Double-curved arch supporting structure used for underground engineering and construction method

A technology for supporting structure and underground engineering, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of many processes, difficult to meet design requirements, heavy structure, etc., to improve the construction progress, shorten the operation time, Ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

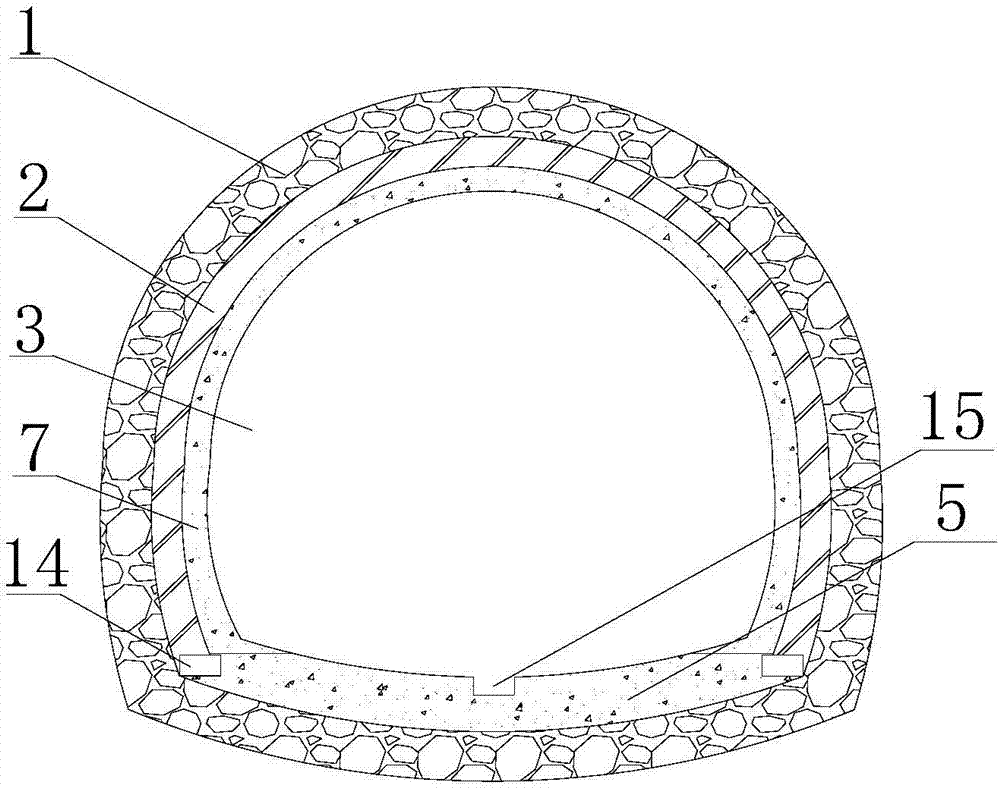

[0062] Example 1: In this example, a tunnel is taken as an example. The stratum around the tunnel is unstable, the surrounding rock type is IV, the cracks are developed, and the water richness is average. The tunnel width is 10m, and the double-curved arch structure is used as the composite lining. initial support.

[0063] Below in conjunction with accompanying drawing concrete description:

[0064] Such as figure 2 , Figure 6 , Figure 7 and Figure 8 As shown, a double-curved arch support structure for underground engineering includes a surrounding rock 1, a double-curved arch support structure 2, and a cave body 3. The double-curved arch support structure 2 is located between the surrounding rock 1 and the cave body 3. A secondary lining 7 is constructed between the double-curved arch support structure 2 and the cave body 3. The double-curved arch support structure 2 includes an arc-shaped arch 4 connected by a plurality of double-curved arch units 6 and a concrete p...

Embodiment 2

[0075] Example 2: In this example, the roadway is taken as an example. The formation around the cave is stable, the surrounding rock type is II, the cracks are relatively developed, and the water-rich property is weak. The width of the tunnel is 4m, and the service life of the roadway is 1 to 3 years. , the double-curved arch structure is used as a single-layer lining support.

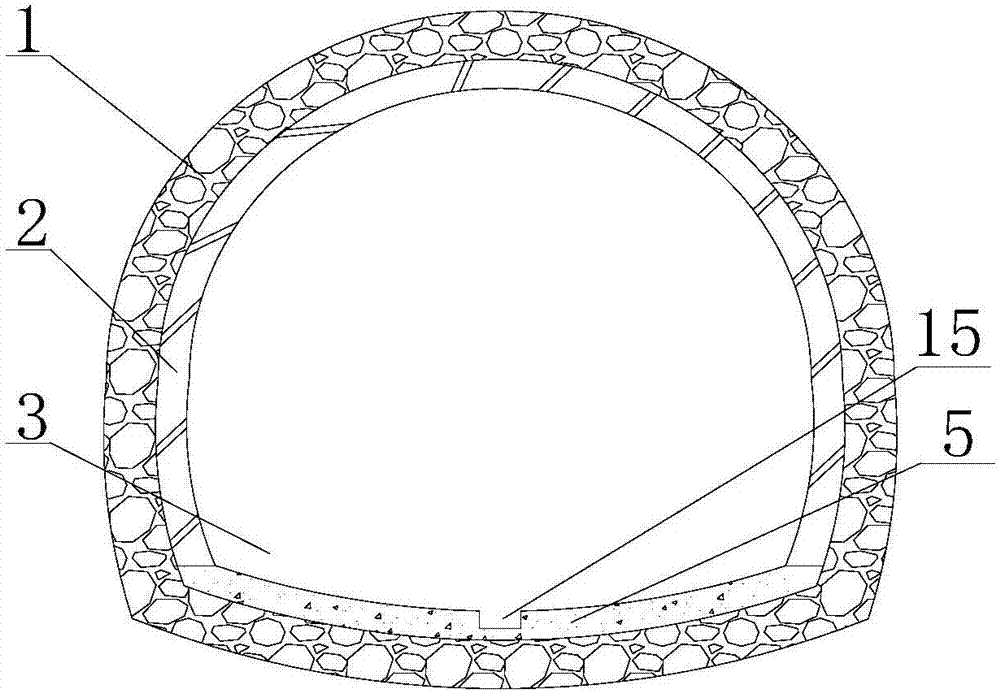

[0076] Such as figure 1 As shown, a double-curved arch support structure for underground engineering includes a surrounding rock 1, a double-curved arch support structure 2 and a cave body 3. The double-curved arch support structure 2 is located between the surrounding rock 1 and the cave body 3, and other The structure is as described in Example 1.

[0077] The construction method of using the double-curved arch structure 2 as a single-layer lining support: includes the following steps:

[0078] Step 1: Determine and prefabricate the double-curved arch unit 6 with a specification of 800mm×1800mm acc...

Embodiment 3

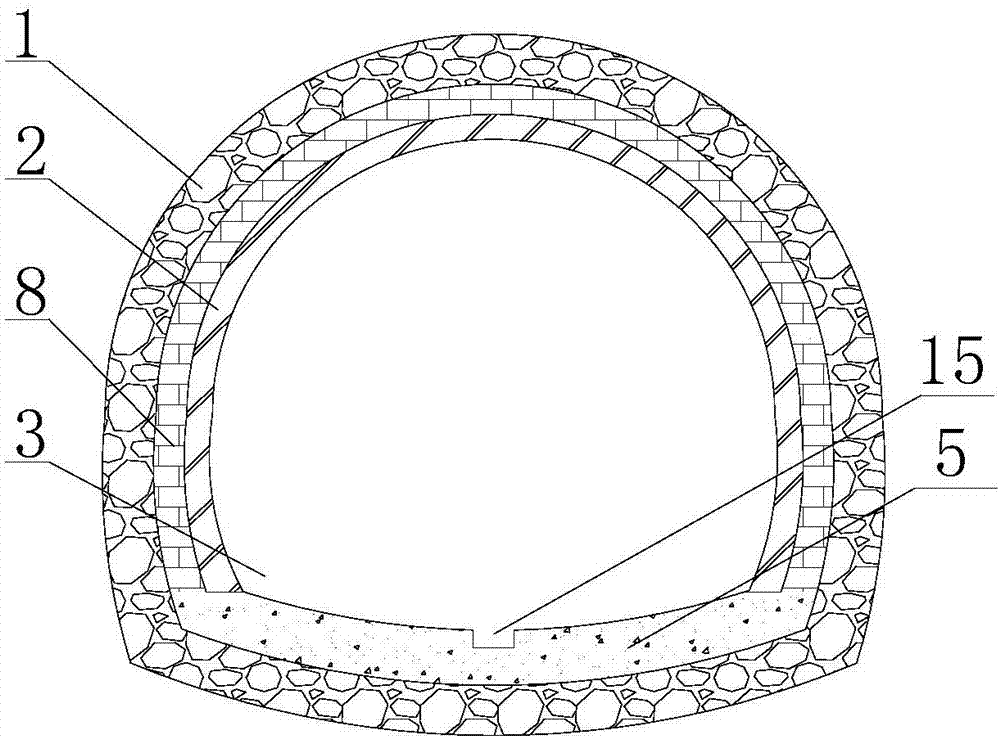

[0084] Embodiment 3: In this embodiment, a tunnel is taken as an example. The stratum around the tunnel is unstable, the surrounding rock type is IV, the cracks are developed, and the water abundance is average. The tunnel width is 10m.

[0085] Such as image 3 As shown, a double-curved arch support structure for underground engineering uses the double-curvature arch support structure 2 as permanent support, and an initial support 8 is constructed between the double-curvature arch support structure 2 and the surrounding rock 1 .

[0086] The above-mentioned double-curved arch structure 2 is used as the construction method of the secondary lining of the composite lining: comprising the following steps:

[0087] Step 1: Determine and prefabricate the double-curved arch unit 6 with a specification of 800mm×1800mm according to the grade of surrounding rock, the magnitude of the load, the excavation contour line of the cave body, and the excavation method;

[0088] Step 2: Perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com