Method for controlling and/or regulating a hydraulic system of a transmission

A hydraulic system and transmission technology, which is applied in fluid pressure actuation system testing, transmission device control, components with teeth, etc., can solve problems that cannot be expressed, characteristic curve clusters are difficult to express and match, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

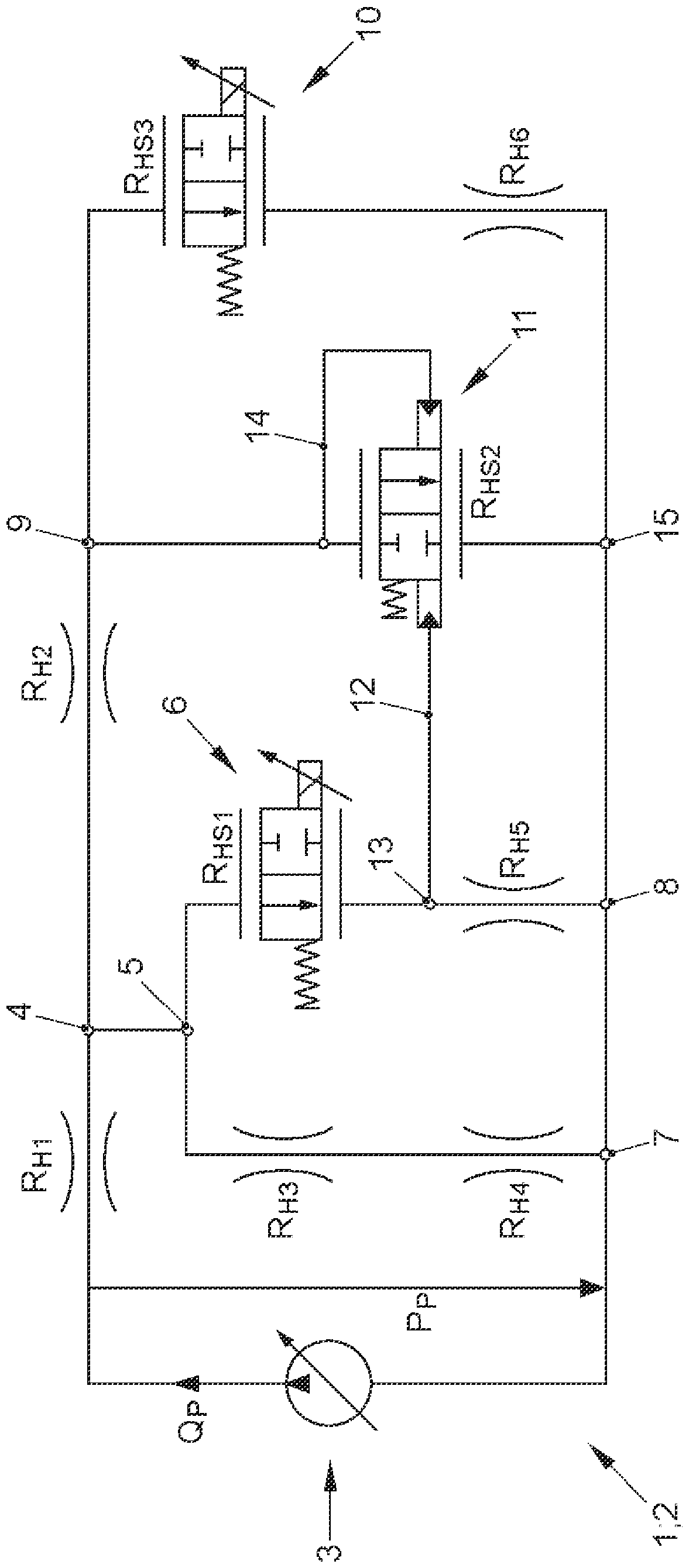

[0050] exist figure 1 A hydraulic system 1 of a motor vehicle transmission is shown very schematically in the form of a network model 2 . Motor vehicle transmissions are designed in particular as dual clutch transmissions. The dual clutch transmission has a dual clutch with two clutches K1 , K2 (not shown). Preferably, the dual clutch transmission also has a clutch K0 for coupling the electric motor to the transmission.

[0051] The hydraulic system 1 has at least one pump 3 . In particular, exactly one pump 3 is present. The pump 3 is preferably designed as an electrically driven pump 3 . In an alternative refinement, a plurality of pumps (not shown) can be present in the hydraulic system 1 , for example a main pump driven by the internal combustion engine of the motor vehicle and an electrically driven additional pump.

[0052] Pump 3 delivers the volume flow Q from the oil sump, which is not drawn in detail P . The pump 3 delivers hydraulic oil, in particular cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com