Quick repair method of leaking hole of rubber hose

A repair method and rubber tube technology, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of easy loosening of fastened parts, easy blockage of debris, and reduced ventilation, so as to achieve a smooth appearance, Less likely to re-leak and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The combustion-supporting gas and combustible gas of the gas cutting torch are conveyed by rubber tubes. When gas cutting is working, the rubber tubes often rub against the ground or other equipment or materials, or roll over them, causing leaks in the rubber tubes. Leakage points cause leakage of combustible gas or combustion-supporting gas, which becomes a hidden danger of accidents.

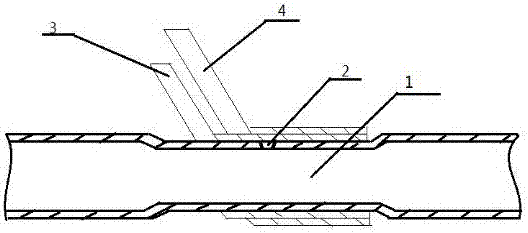

[0020] After the rubber tube leak occurs, high-pressure gas will leak from the leak, and the location of the leak can be confirmed through sound, feeling and visual inspection. After determining the location of the leak point, as attached figure 1 As shown, stretch a section of rubber tube 1 containing leak point 2 with both hands or clamps to make it produce elastic contraction deformation. Wrap the leak hole 2 and the rubber tube 1 tightly with plastic tape 3. The plastic tape 3 is tightly wound on the outer layer with electrical insulating tape 4 . The electrical insulating tape 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com