Fracturing fluid sand-suspending capability evaluation device and evaluation method

An evaluation device and evaluation method technology, applied in the direction of material inspection products, etc., can solve the problems that cannot quantify the change law of proppant settlement, affect the effectiveness of fracturing construction of fracturing fluid and proppant optimal fracturing scheme, and reach the experimental range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

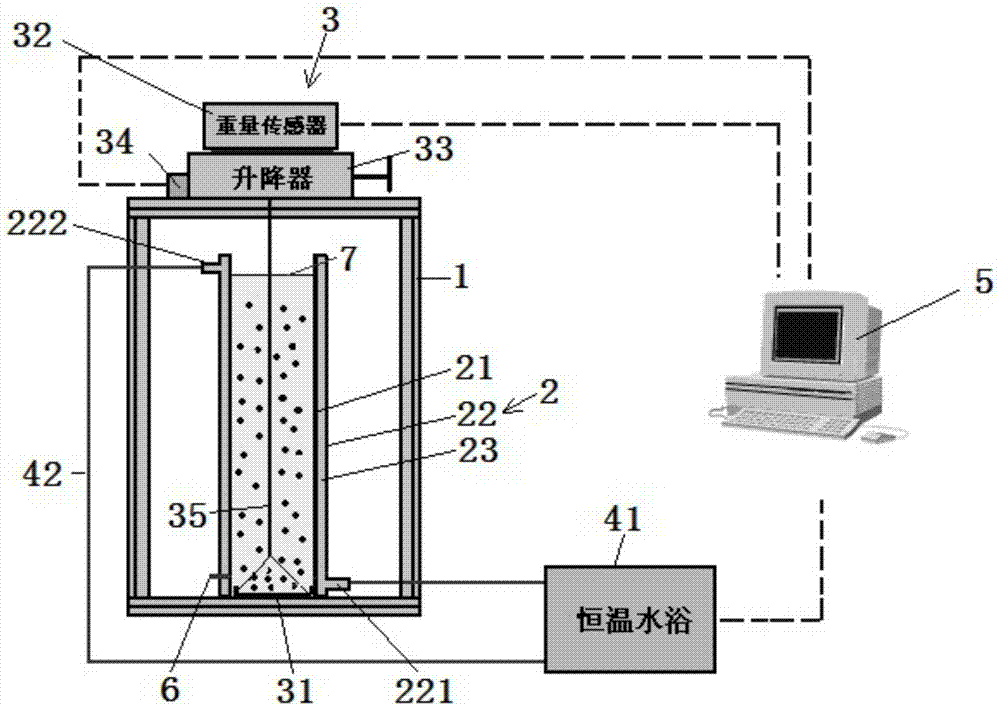

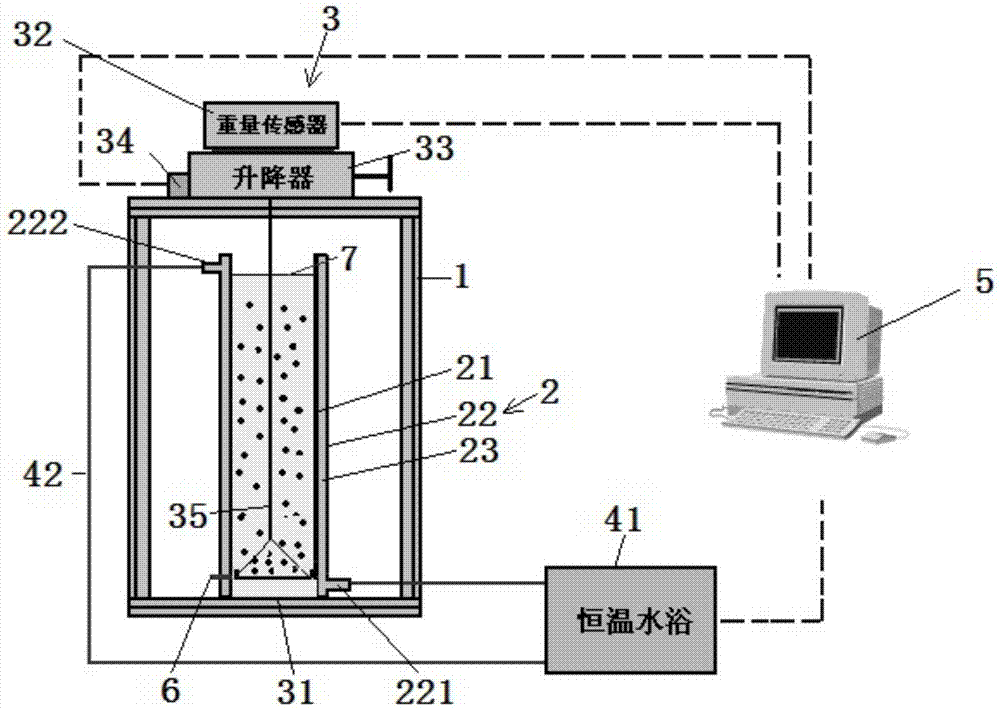

[0038] first as figure 1 As shown in , it is a schematic structural diagram of the evaluation device for sand-carrying capacity of fracturing fluid. The present invention provides an evaluation device for the sand-carrying capacity of fracturing fluid, which is mainly suitable for the testing and research of suspended sand and settlement performance of fracturing fluid. The evaluation device mainly includes: a main frame structure 1, a visual suspended sand measurement container 2, and a proppant Quality measurement system 3 , temperature control system 4 and data acquisition and processing system 5 .

[0039] The visualized suspended sand measuring container 2 is installed on the bottom of the main frame structure 1 and includes: an inner cylinder 21 of the suspended sand measuring container, an outer cylinder 22 of the suspended sand measuring container and an annular sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com