Annular neighborhood reference contour line-based grid model adaptive layering method

A grid model, contour line technology, applied in image data processing, instruments, additive processing, etc., can solve the problems of difficult to achieve high-precision and high-efficiency layered slicing, difficult models, model contour errors, etc. The effect of traversing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

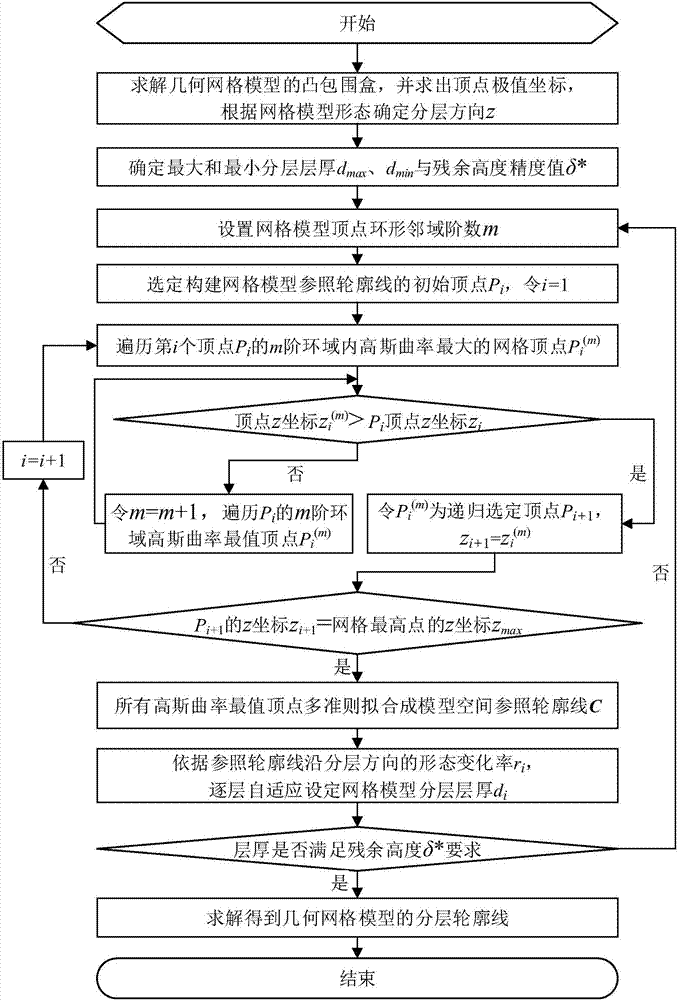

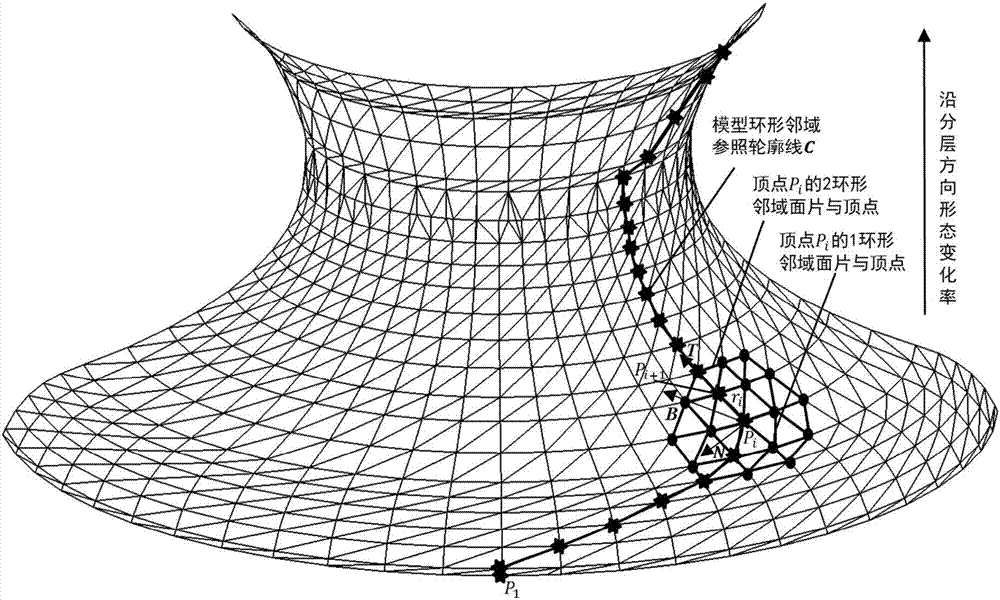

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

[0044] Embodiments of the present invention are as follows:

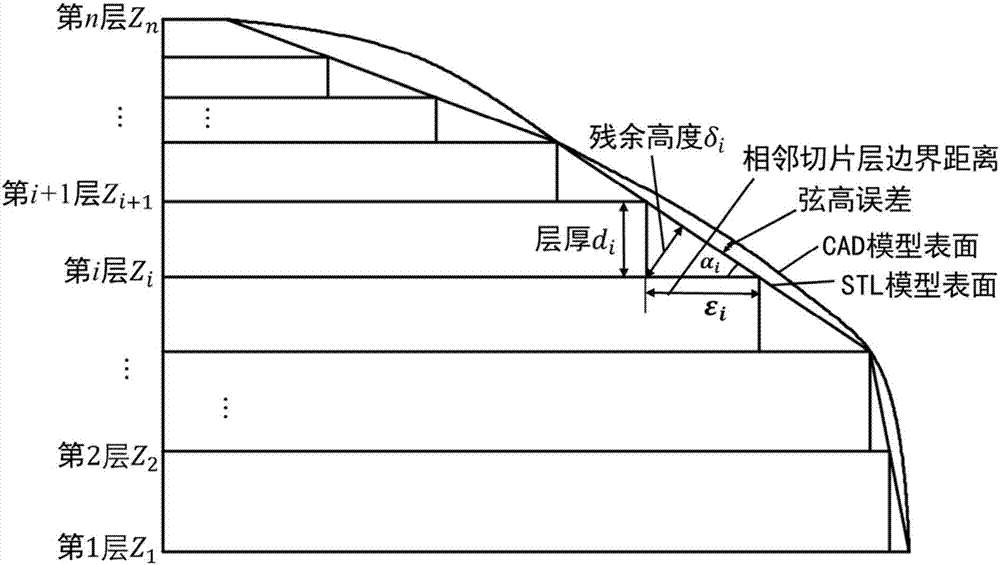

[0045] Such as figure 2 Shown is a schematic diagram of the layered residual height of the grid model of the present invention. The evaluation index of the step effect during 3D printing adopts the residual height, which refers to the distance from the vertex of the curved triangle to the surface of the model along the direction of the normal vector of the model surface. The i-th layer is layered, and the maximum residual height of all its patches is δ i = d i ·|cosα i |, d i is the layer thickness, α i is the angle between the patch and the horizontal direction, which can be obtained from the component vector of the normal vector of the patch in the Z direction, and the residual height δ i Can be expressed as:

[0046]

[0047] ε i It is the boundary distance between the adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com