Carbon dioxide laser tube with new structure and vacuum flange modules

A vacuum flange, carbon dioxide technology, applied in lasers, laser parts, laser parts and other directions, can solve the problems of difficult to guarantee the quality of carbon dioxide laser tubes, unable to place the lens protective cover, difficult to ensure the consistency of accuracy, etc. Dependence on the grinding accuracy of the nozzle, good sealing effect, easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

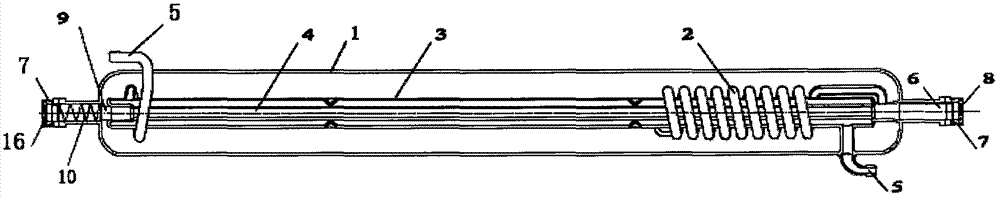

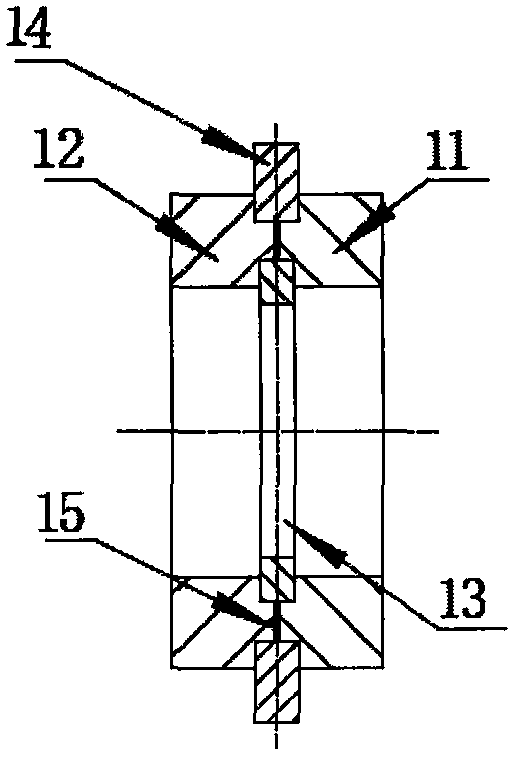

[0013] Such as Figure 1 to Figure 2 As shown, a carbon dioxide laser tube with a vacuum flange assembly of a new structure includes a tube body and a lens, and also includes two vacuum flange assemblies 7, and the two vacuum flange assemblies 7 are glued to the nozzles at both ends of the tube body. Then, the lens is installed on the vacuum flange assembly 7 connected to the nozzle, and the lens is a total reflection mirror 8 or an output reflection mirror 16; the glass part of the carbon dioxide laser tube is composed of a gas storage tube 1, a gas return tube 2, a water cooling tube 3, and a discharge tube 4 and water nozzle 5, the pipe body is a three-layer casing structure, the innermost layer is the discharge tube 4, the middle is the water-cooled tube 3, the outermost layer is the gas storage tube 1, and the gas return tube 2 is used to connect the discharge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com