A device for automatically preparing foam stock solution from foam powder

An automatic preparation and foam technology, applied in fire protection equipment and other directions, can solve the problems of fire truck limitation, large volume occupied by foam stock solution, and limited volume of fire truck, and achieve the effect of saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

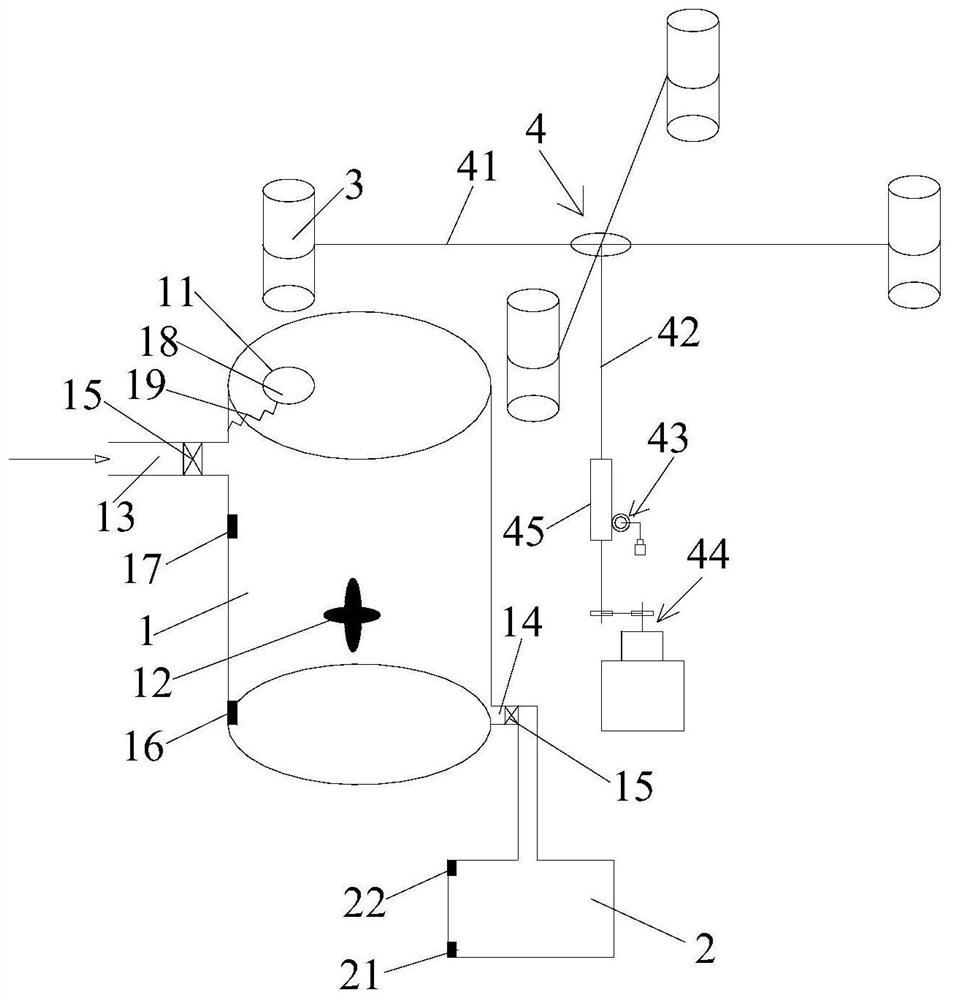

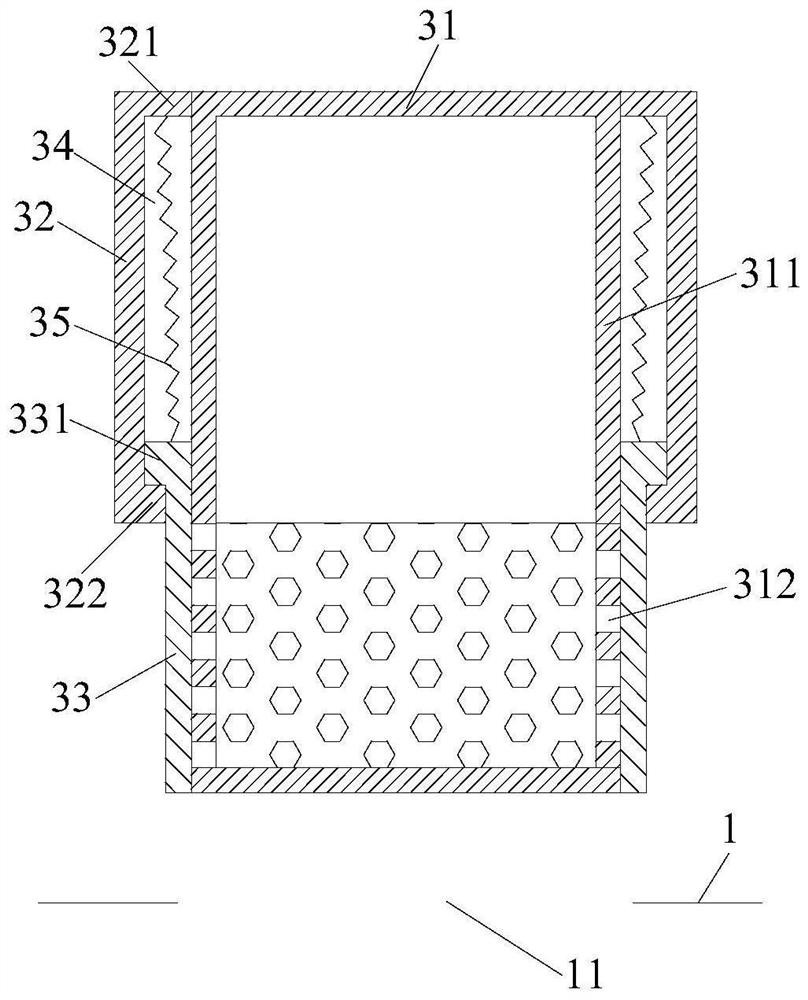

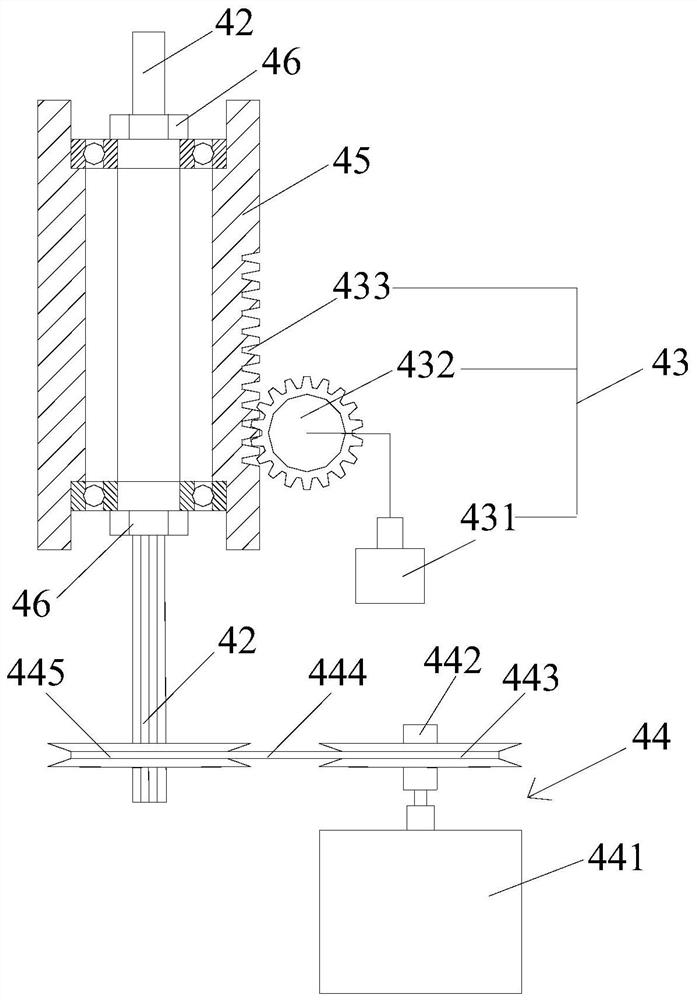

[0030] Please combine figure 1 and figure 2 As shown: a device for automatically preparing foam stock solution from foam powder provided in this embodiment, including a mixing tank 1, a foam stock solution storage tank 2, a foam powder storage tank 3 and a drive for driving the foam powder storage tank 3 to lift and rotate Platform 4, the top of the mixing tank 1 is provided with a powder feeding hole 11, the mixing tank 1 is provided with an agitator 12, and the upper part of the mixing tank 1 is provided with a water inlet 13, and the lower part is provided with a foam liquid outlet 14 , the foam stock solution outlet 14 is in communication with the foam stock solution storage tank 2; the foam powder storage tank 3 includes a tank body 31, and the peripheral side wall of the tank body 31 is divided into a sealing part 311 and an opening part from top to bottom 312, a fixed sleeve 32 is provided on the outer periphery of the tank at the sealing portion 311, and a movable sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com