A kind of superfine dry powder fire extinguishing agent and preparation method thereof

A technology of ultra-fine dry powder and fire extinguishing agent, which is applied in fire protection equipment and other directions, can solve the problems of increasing the cost of fire fighting for users or armed police, high cost of fire extinguishing agent, and high price of ammonium polyphosphate, so as to achieve low substrate cost and less preparation equipment. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

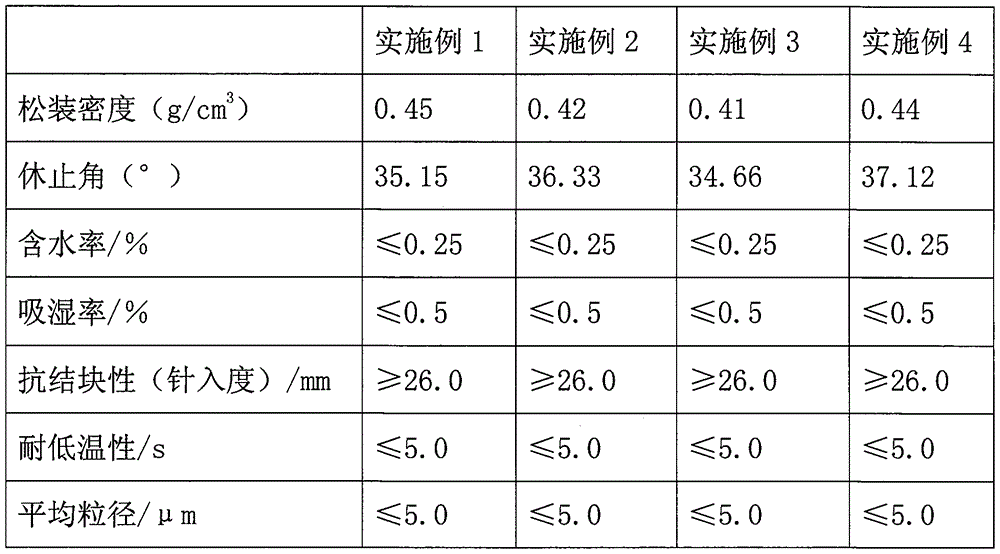

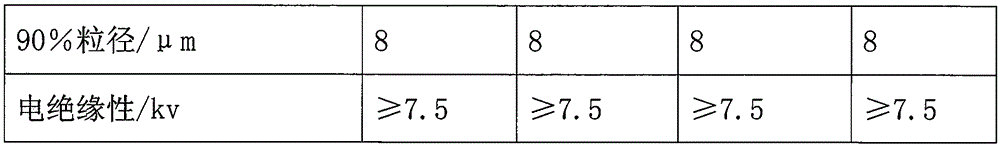

Examples

Embodiment 1

[0019] The preparation of superfine dry powder fire extinguishing agent specifically comprises the following steps:

[0020] Step 1, each raw material component is taken by weighing 1 ton of total raw material: sodium dodecylbenzenesulfonate 2Kg, mica powder 80Kg, hydrophobic white carbon black 60Kg, polyether modified silicone oil (high fluorine silicone oil) 7Kg, hydrogen-containing 2Kg of silicone oil, 1.8Kg of water, 3.2Kg of gasoline, and the remaining materials are 422Kg of magnesium hydroxide and 422Kg of aluminum hydroxide, wherein the mass ratio of magnesium hydroxide and aluminum hydroxide is 1:1;

[0021] Step 2, sodium dodecylbenzenesulfonate (average particle diameter is less than 2 μm), mica powder (average particle diameter is less than 2 μm), magnesium hydroxide (average particle diameter is less than 2 μm), aluminum hydroxide (average particle diameter is less than 2 μm) ) are mixed and stirred evenly after being dried respectively to obtain the intermediate m...

Embodiment 2

[0026] The preparation of superfine dry powder fire extinguishing agent specifically comprises the following steps:

[0027] Step 1, each raw material component is taken by weighing 1 ton of total raw material: sodium dodecylbenzene sulfonate 2.5Kg, mica powder 100Kg, hydrophobic white carbon black 50Kg, polyether modified silicone oil (high fluorine silicone oil) 8Kg, containing 3Kg of hydrogen silicone oil, 2.5Kg of water, 3Kg of gasoline, and the remaining material is 437Kg of magnesium hydroxide and 394Kg of aluminum hydroxide, wherein the mass ratio of magnesium hydroxide and aluminum hydroxide is 1: 0.9;

[0028] Step 2, sodium dodecylbenzenesulfonate (average particle diameter is less than 2 μm), mica powder (average particle diameter is less than 2 μm), magnesium hydroxide (average particle diameter is less than 2 μm), aluminum hydroxide (average particle diameter is less than 2 μm) ) are mixed and stirred evenly after being dried respectively to obtain the intermediat...

Embodiment 3

[0033] The preparation of superfine dry powder fire extinguishing agent specifically comprises the following steps:

[0034] Step 1, each raw material component is taken by weighing 1 ton of total raw material: sodium dodecylbenzene sulfonate 3Kg, mica powder 120Kg, hydrophobic white carbon black 35Kg, polyether modified silicone oil (high fluorine silicone oil) 6Kg, hydrogen-containing 1.5Kg of silicone oil, 1.5Kg of water, 5Kg of gasoline, and the remaining materials are 331Kg of magnesium hydroxide and 497Kg of aluminum hydroxide, wherein the mass ratio of magnesium hydroxide and aluminum hydroxide is 1: 1.5;

[0035] Step 2, sodium dodecylbenzenesulfonate (average particle diameter is less than 2 μm), mica powder (average particle diameter is less than 2 μm), magnesium hydroxide (average particle diameter is less than 2 μm), aluminum hydroxide (average particle diameter is less than 2 μm) ) are mixed and stirred evenly after being dried respectively to obtain the intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com