An ore fluidized roasting device and method with adjustable unidirectional and bidirectional discharge

A fluidized roasting and adjustable technology, used in the field of ore fluidized roasting and metallurgy, can solve the problems of difficult adjustment and control of operating parameters, small processing capacity per unit of material, etc., achieve easy control and large-scale, eliminate dead zones , the effect of large heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better explain the present invention, the specific implementation manners of the present invention will be described in detail below with reference to the drawings.

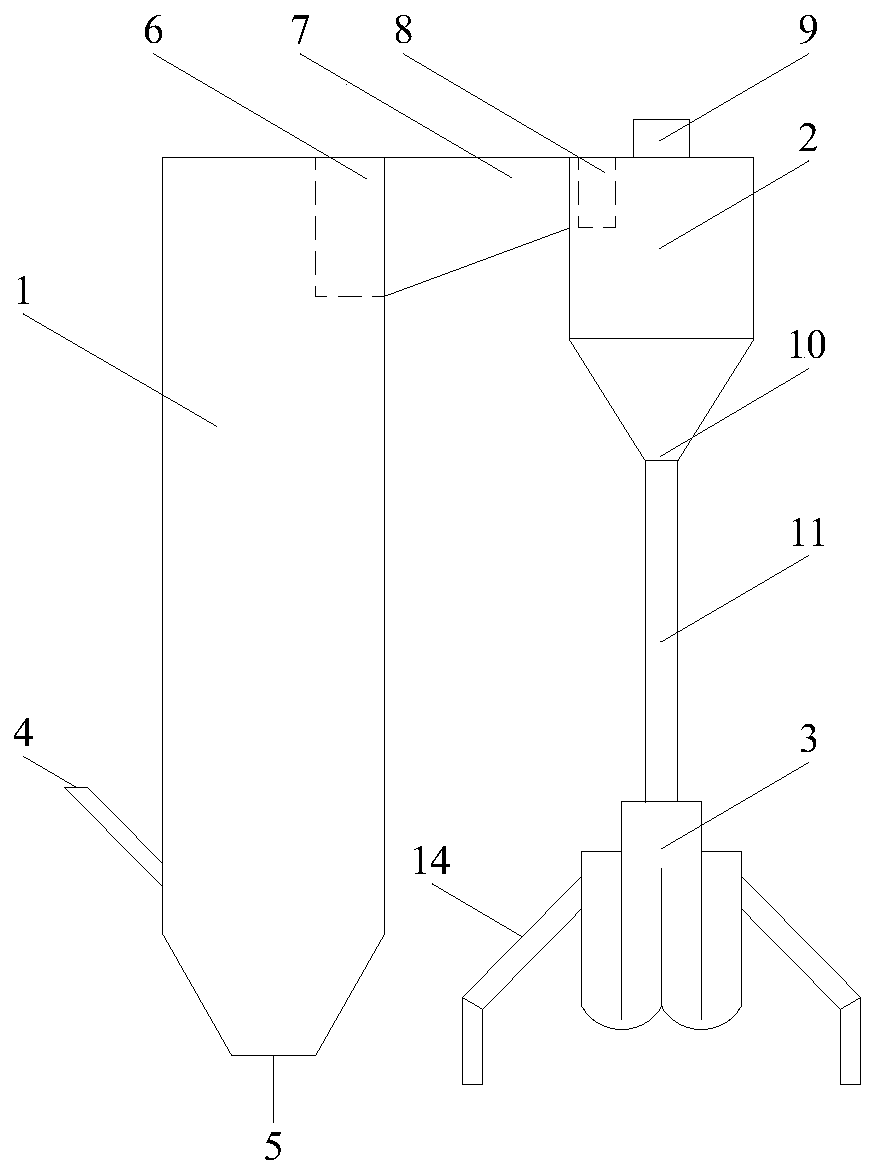

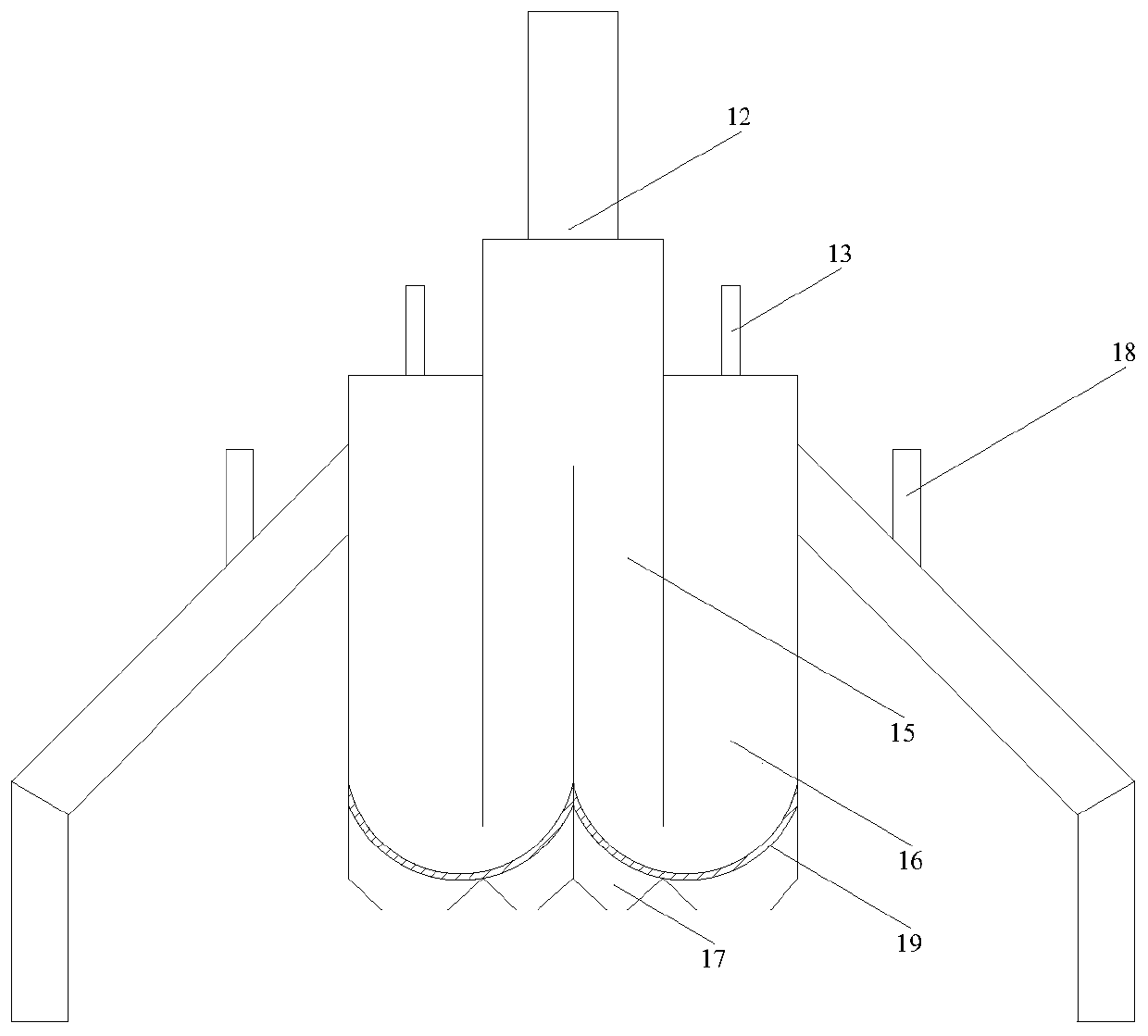

[0033] Such as figure 1 An ore fluidized roasting device with adjustable unidirectional and bidirectional discharge includes a preheater 1, a heat separator 2 and an adjustable roaster 3, all of which have high-temperature resistant fireproof linings. The side of the preheater 1 is connected to the raw material inlet and the screw feeder 4, the bottom end is the flue gas inlet 5, and the gas material mixing outlet 6 at the top is connected to the volute 8 at the top of the heat separator through the connecting pipe 7; the heat separator 2 The top end is a hot gas outlet 9, the bottom end is a discharge port 10, and is connected to the top feed port 12 of the adjustable roaster 3 through a vertical channel 11; the bottom of the adjustable roaster 3 is provided with a plurality of nitrogen and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com