A method for preparing nanometer erbium oxide by reaction ball milling

An erbium oxide, ball milling technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of poor particle dispersion and uniformity, slow reaction speed of precipitation method, small specific surface area, etc., to achieve controllability High, short preparation cycle, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

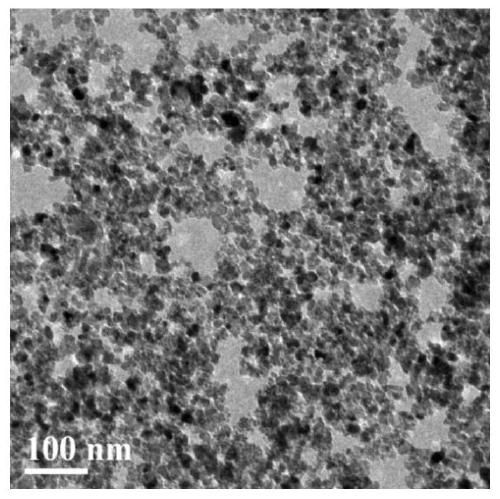

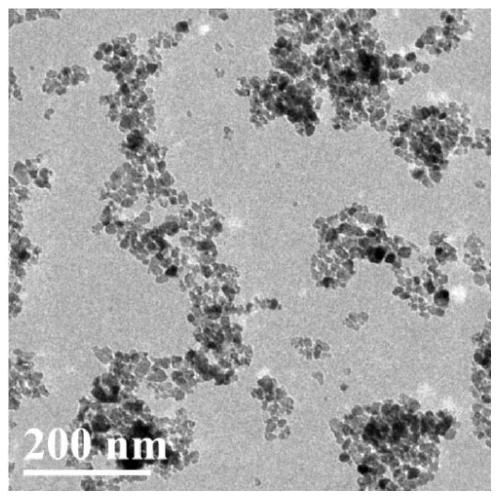

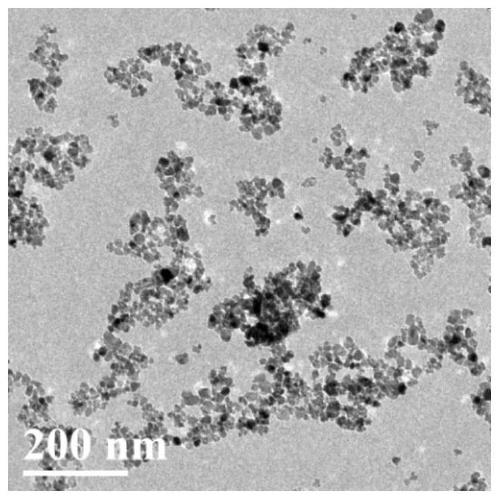

Image

Examples

Embodiment 1

[0034] A method for preparing nano-erbium oxide by reaction ball milling, the specific process is as follows:

[0035] (1) Get 9.2L of 1.7mol / L erbium chloride solution, add 78.2L deionized water (50°C-60°C), and prepare 0.2mol / L erbium chloride solution A;

[0036] (2) Ultrasonic dispersion of 0.2g graphene oxide in 50ml of absolute ethanol for a dispersion time of 30min to obtain alcohol solution B of graphene oxide;

[0037] (3) Take 90g of sodium dodecylbenzenesulfonate, put it into 100ml of deionized water, the temperature of the deionized water is 50°C-60°C, stir until fully dissolved, and obtain solution C;

[0038] (4) get sodium carbonate 4200g, as precipitant powder D;

[0039] (5) In the grinding cavity of the planetary ball mill with a grinding cavity volume of 100L, add zirconia zirconium beads with a diameter of 1 μm, the filling volume of the zirconium oxide zirconium beads in the grinding cavity of the ball mill accounts for 50% of the grinding cavity volume, ...

Embodiment 2

[0046] A method for preparing nano-erbium oxide by reaction ball milling, the specific process is as follows:

[0047] (1) Get 9.2L of 1.7mol / L erbium chloride solution, add 31.28L deionized water (50°C-60°C), and prepare 0.5mol / L erbium chloride solution A;

[0048] (2) Ultrasonic dispersion of 0.3g graphene oxide in 50ml of absolute ethanol, dispersion time 50min, to obtain alcohol solution B of graphene oxide;

[0049] (3) Take 120g of sodium dodecylbenzenesulfonate, put it into 100ml of deionized water (50°C-60°C) and fully dissolve it to obtain solution C;

[0050] (4) Take 3200g of sodium bicarbonate and 1150g of sodium oxalate respectively, and fully mix to obtain powder D;

[0051] (5) In the grinding cavity of the planetary ball mill with a grinding cavity volume of 100L, add zirconia zirconium beads with a diameter of 1 μm, the filling volume of the zirconium oxide zirconium beads in the grinding cavity of the ball mill accounts for 50% of the grinding cavity volume, ...

Embodiment 3

[0058] A method for preparing nano-erbium oxide by reaction ball milling, the specific process is as follows:

[0059] (1) Get 9.2L of 1.7mol / L erbium nitrate solution, add 39.1L deionized water (50°C-60°C), and prepare 0.4mol / L erbium nitrate solution A;

[0060] (2) Ultrasonic dispersion of 0.4g graphene oxide in 50ml of absolute ethanol, dispersion time 60min, to obtain alcohol solution B of graphene oxide;

[0061] (3) Take 120 g of sodium dodecylbenzene sulfonate, put it into 100 ml of deionized water (50°C-60°C) and fully dissolve it to obtain solution C;

[0062] (4) Take 2000g of sodium carbonate, 1100g of sodium bicarbonate and 1100g of sodium oxalate respectively, and fully mix to obtain powder D;

[0063] (5) In the grinding cavity of the planetary ball mill with a grinding cavity volume of 100L, add zirconia zirconium beads with a diameter of 1 μm, the filling volume of the zirconium oxide zirconium beads in the grinding cavity of the ball mill accounts for 50% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com