Spraying device for inner surfaces of pipe fittings

A technology of spraying device and inner surface, applied in the direction of spraying device, etc., can solve the problem of high price, achieve the effect of simple and lightweight structure, meet various processing requirements, and process a large range of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

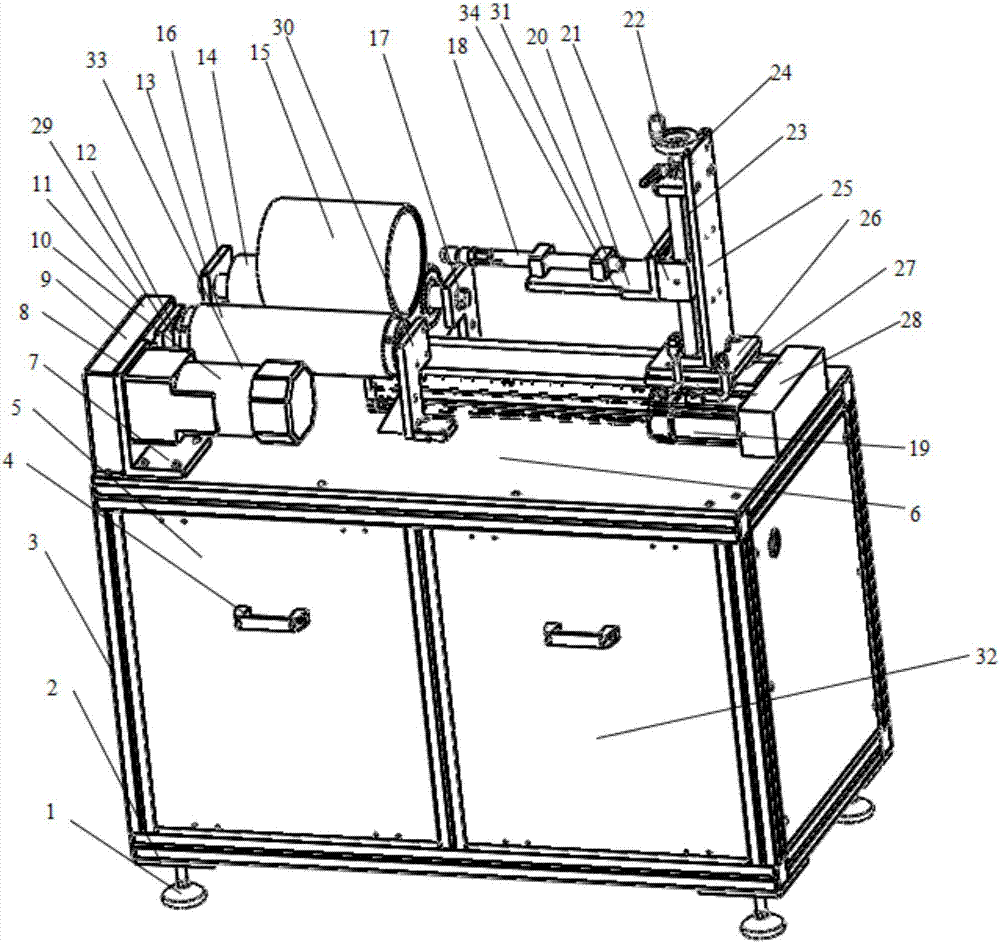

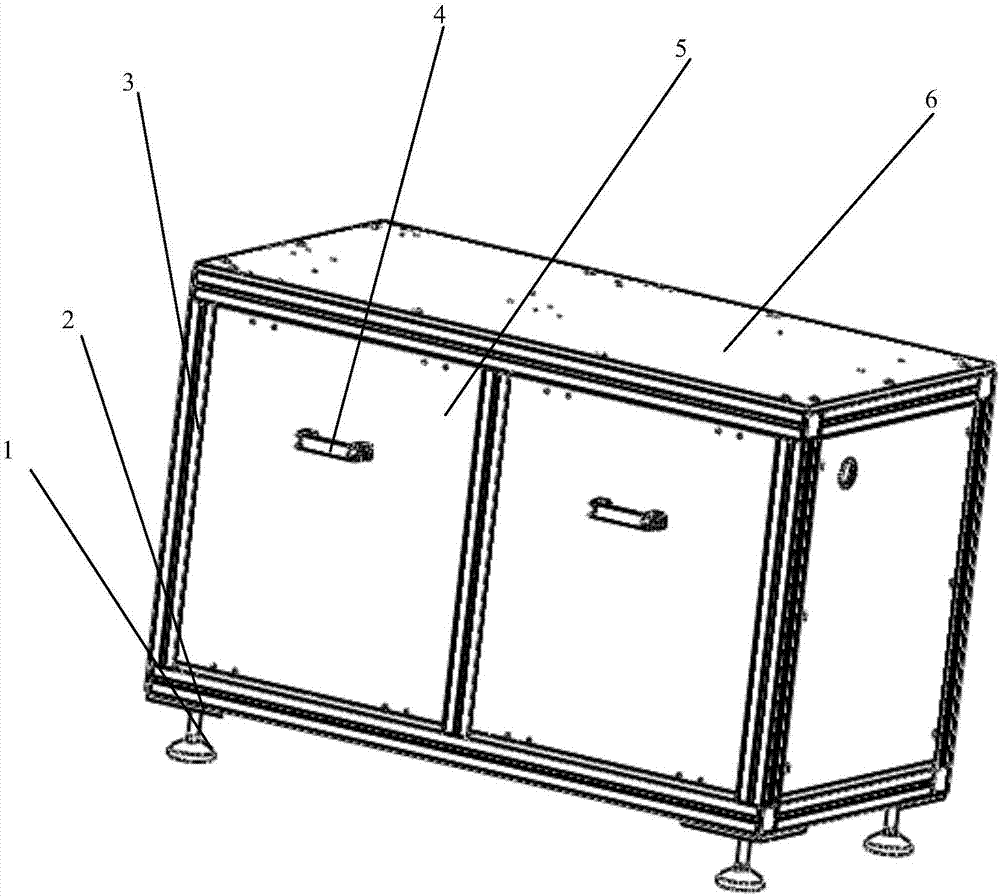

[0026] A spraying device for the inner surface of pipe fittings provided by the present invention includes a lower cabinet body 32 , a pipe fitting speed regulating mechanism 33 and a spraying mechanism 34 ;

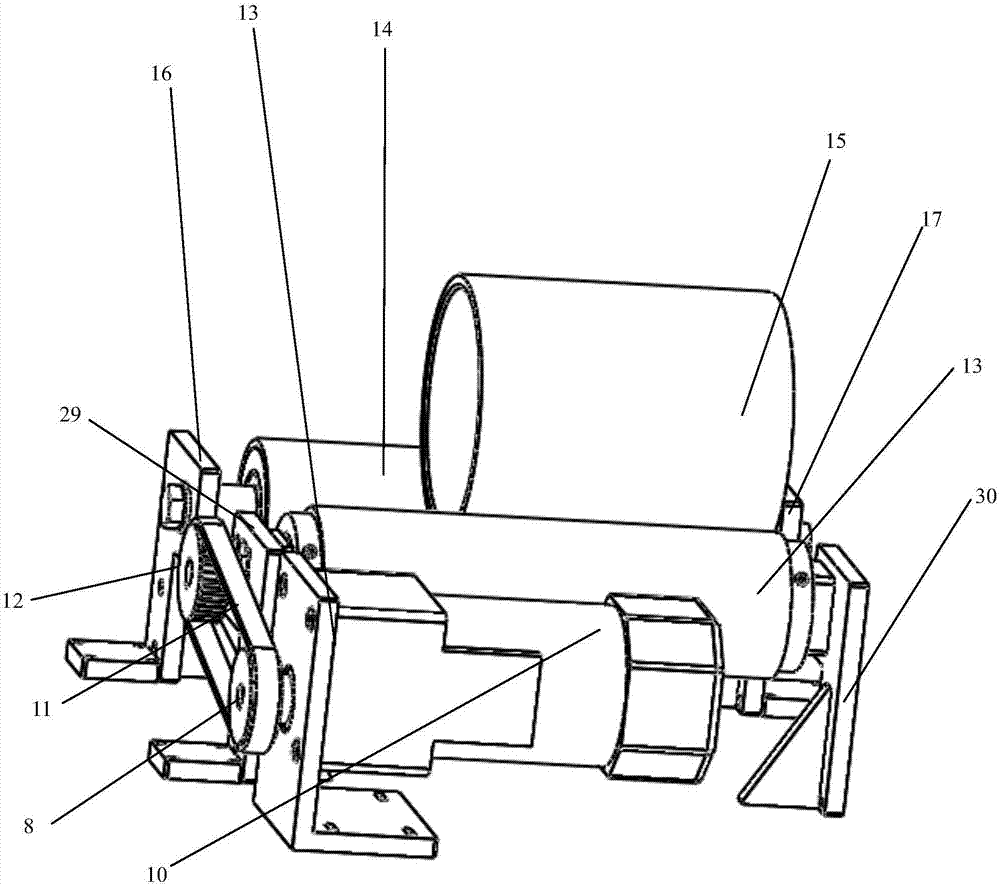

[0027] The pipe speed regulating mechanism 33 includes a motor mounting plate 7, a first driving device 10, a driving pulley 8, a synchronous belt 11, a driven pulley 12, a driving roller 13, a workpiece 15, a driven roller 14 and a rotating mechanism protective cover 9, The first driving device 10 is arranged parallel to the driving roller 13 and the driven roller 14 . The motor mounting plate 7 is fixed on the mounting plate 6 of the lower cabinet 32 by bolts, and the first driving device 10 is mounted on the motor mounting plate 7 by bolts; the workpiece 15 is placed between the driving roller 13 and the driven roller 14, and the workpiece 15 The outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com