Rolling schedule optimization method based on comprehensive equal load function

An optimization method and technology of rolling schedule, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as empirical load distribution is not the optimal rolling schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

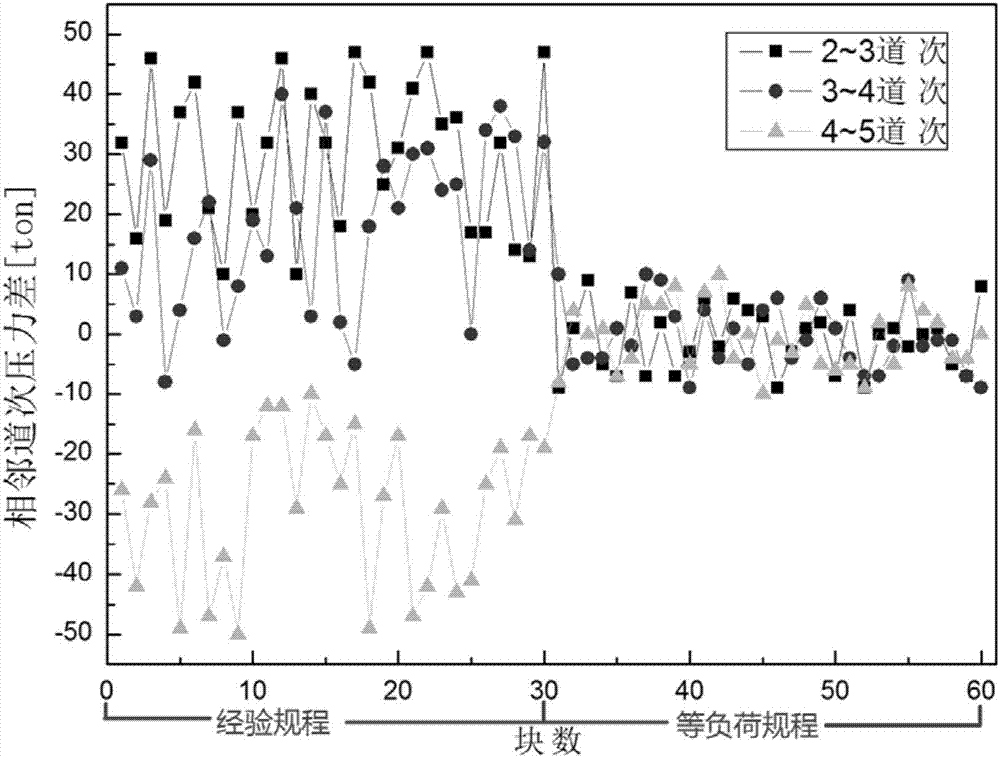

[0026] The technical solution of the present invention will be further described below in conjunction with specific practical application effects.

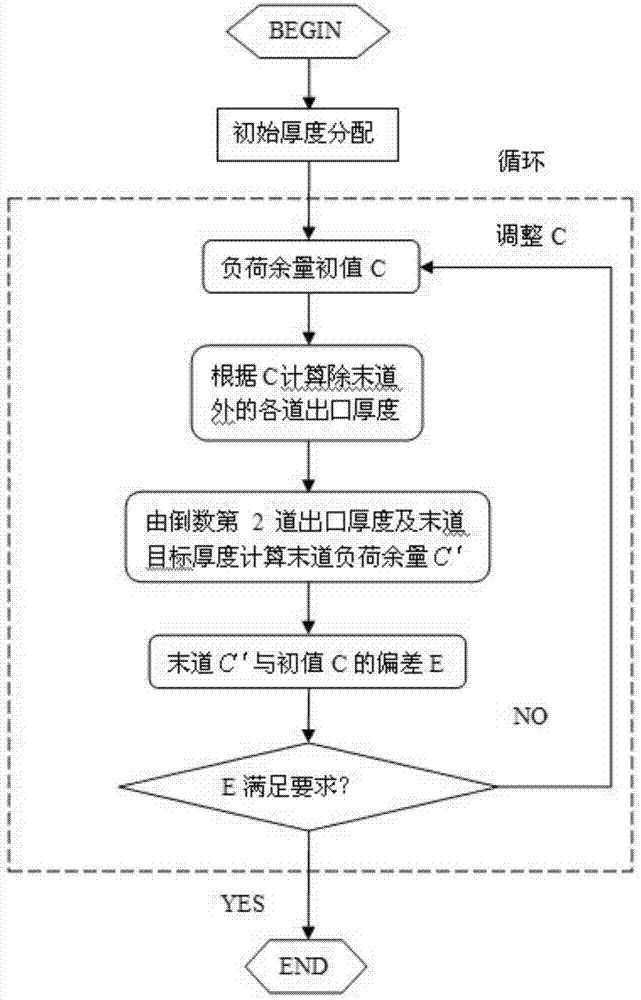

[0027] Such as figure 1 Shown, a kind of rolling optimization method based on comprehensive equal load function of the present invention, this scheme comprises the following steps:

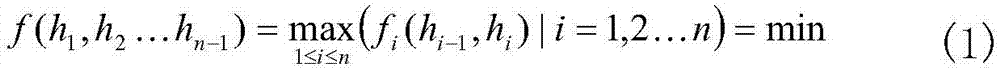

[0028] 1) According to the incoming material thickness h 0 , finished product thickness h n , process given thickness allocation scheme h 1 、h 2 ,... h n-1 And rolling force model P=Bl' c KQ p Calculate the rolling force P for each pass i , and then the maximum allowable rolling force P for each pass maxi According to the constraint conditions of the process equipment, the corresponding load margin value of each pass is calculated Where i=1,2,...,n, i is the pass number, n is the total number of passes, P is the calculated value of rolling force, B is the width of the rolled piece, L' c is the horizontal projection length of the contact ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com