Positioning marking method, device and system of in-built part of rotating shell

A technology for positioning marks and the inner surface of the shell, applied in workshop equipment, manufacturing tools, etc., can solve the problems of occlusion of the projection path and low spatial opening, and achieve the effect of improving positioning accuracy, realizing high-precision positioning, and eliminating alignment errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

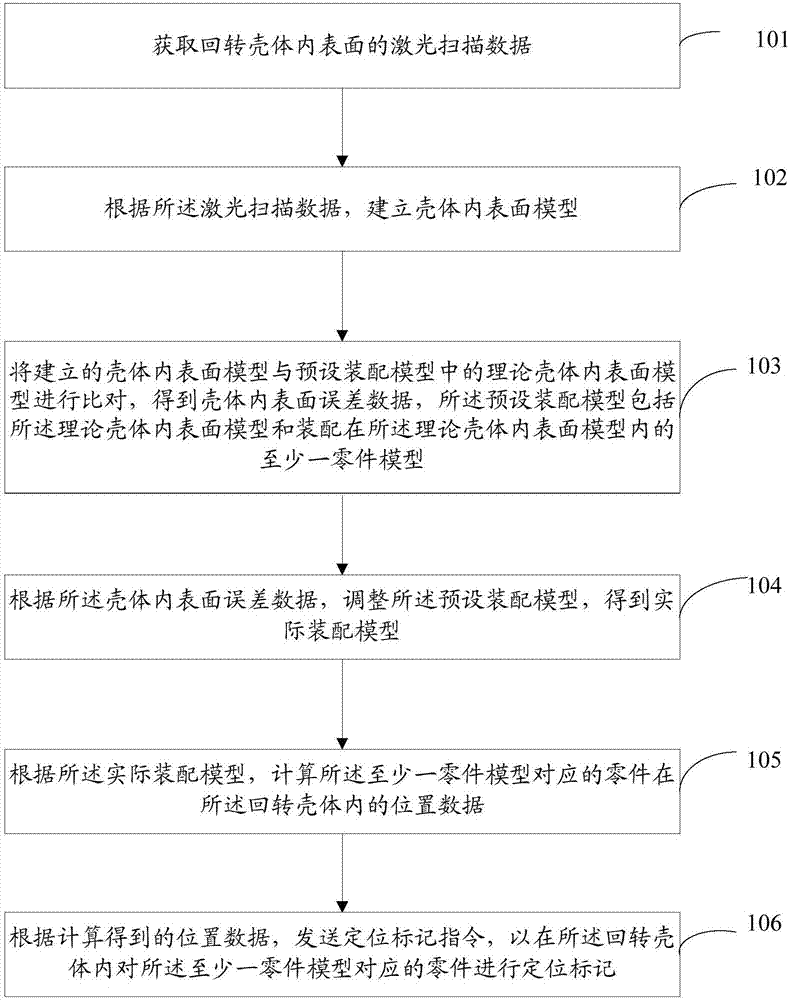

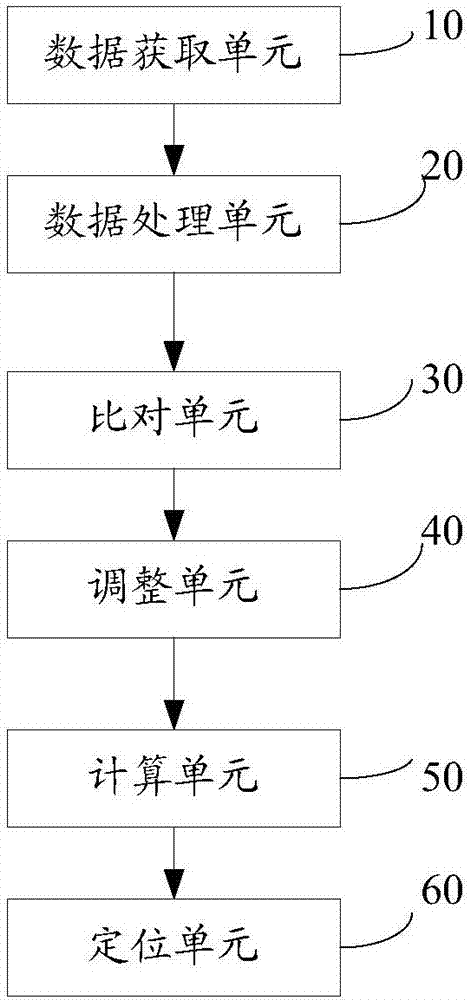

Method used

Image

Examples

specific Embodiment

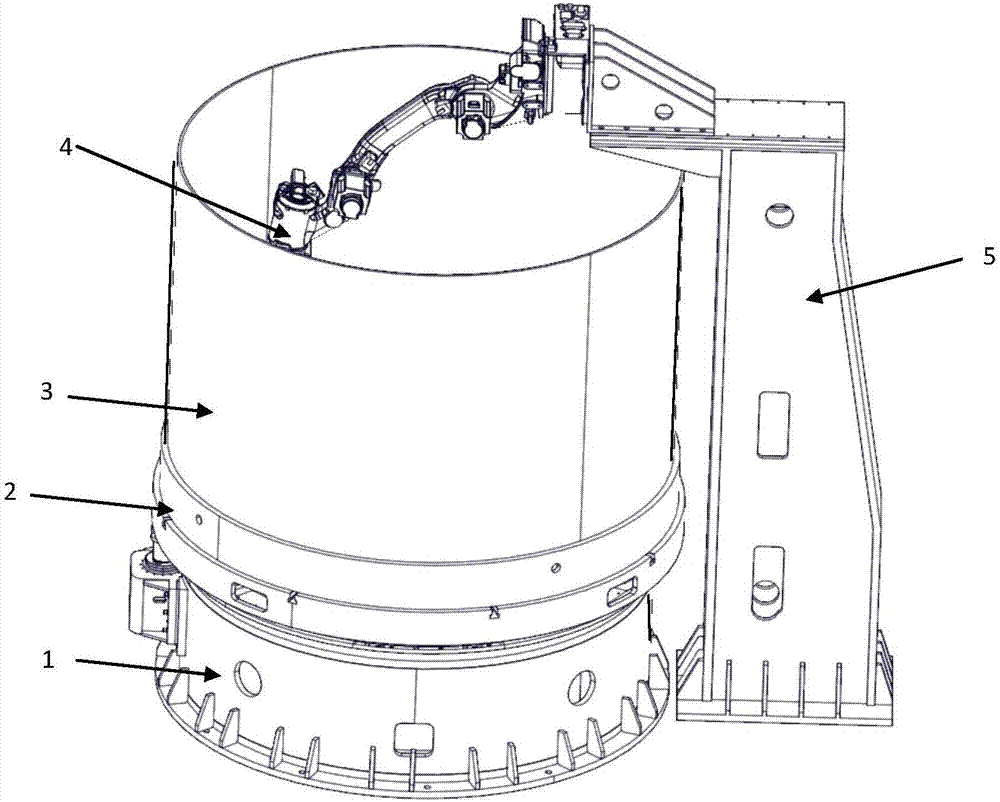

[0119] The device comprises a numerical control turntable 1, a positioning disc 2, a robot 4 (joint arm robot), an auxiliary tooling 5, a robot end clamping mechanism 6, a laser scanner 7, and a jetting dock 8. Among them, the rotary housing 3 is fixed on the positioning disc 2 through the positioning pin 9, and the positioning joint 10 is installed on the positioning disc 2, and the positioning disc 2 is installed on the numerical control turntable 1 through the positioning joint 10, and the positioning is realized by the positioner 11. Disc positioning, tension. Thereby, the coaxiality between the rotary housing 3 and the numerically controlled turntable 1 is ensured, and alignment in this way is high in efficiency and simple in operation, and there is no need to continuously adjust the position of the rotary housing 3 on the numerically controlled turntable 1 by using a traditional dial indicator.

[0120] After the rotary housing 3, the positioning disk 2 and the numerical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com