Resin injection sleeve for RTM (Resin Transfer Molding) die

A glue injection and mold technology, applied in the field of easy-to-clean glue injection auxiliary devices, can solve the problems of increasing costs, reducing work efficiency, scratching the inner hole of the glue injection sleeve, etc., to meet the sealing requirements, increase the service life, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

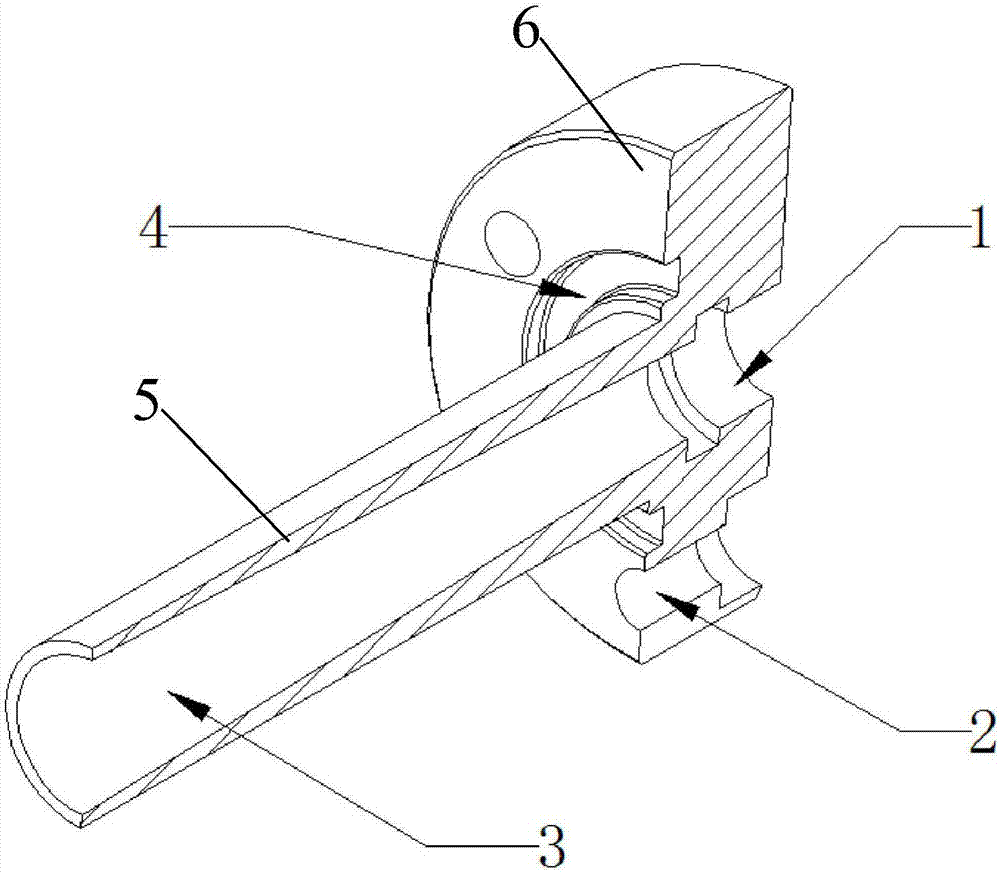

[0011] Depend on figure 1 It can be seen that an RTM mold injection sleeve includes a rubber injection sleeve body 5, a sealing groove 4 for placing an O-ring is provided between the rubber injection sleeve body 5 and the mold 6, and a countersink hole 2 is provided on the injection sleeve. The bolt fastens the injection sleeve and the mold through the counterbore 2 and compresses the O-ring; one end of the injection sleeve body is provided with a pipe thread 1 connected to the outer wire, and a tapered inner wall 3 is arranged inside the injection sleeve body. The pipe thread 1 is connected to the external pipeline of the mold including the standard pipe thread outer wire to ensure the sealing requirements between the mold and the injection sleeve; three hexagon socket head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com