Bracket type gas distribution pipe lifting device and aerator pipe maintenance and replacement method

A replacement method and technology for air distribution pipes, which are applied in the directions of portable lifting devices, hoisting devices, chemical instruments and methods, etc., can solve the problems of lack of time for cleaning and maintenance, prone to shaking, and inability to use, so as to achieve a simple maintenance and replacement method. Flexible, ensure aeration effect, ensure the effect of running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

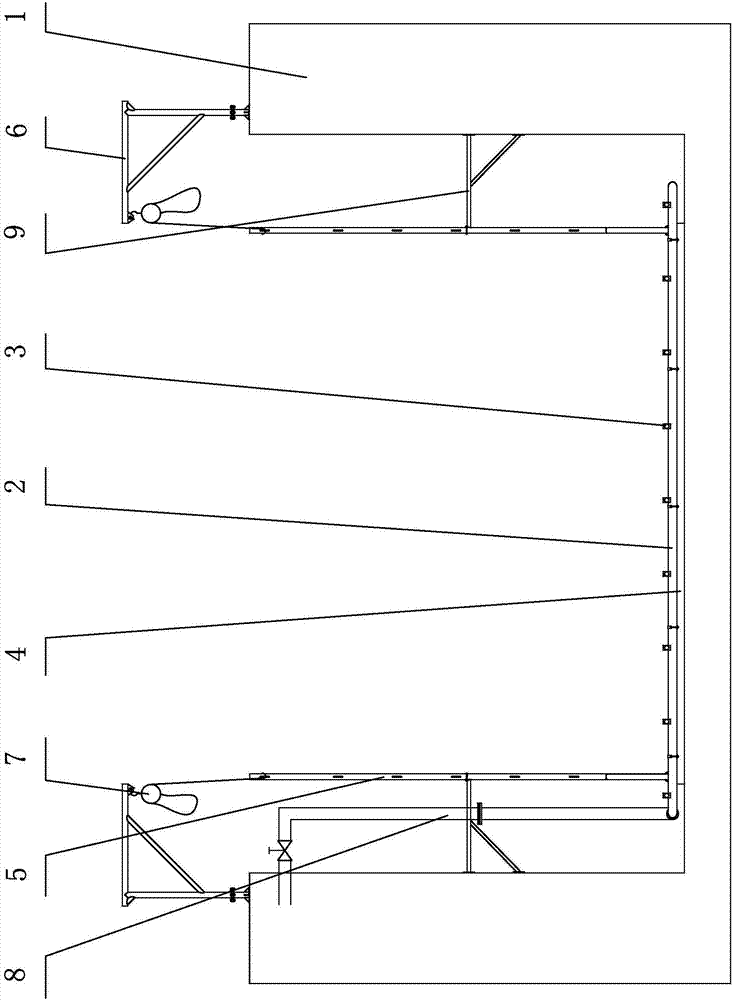

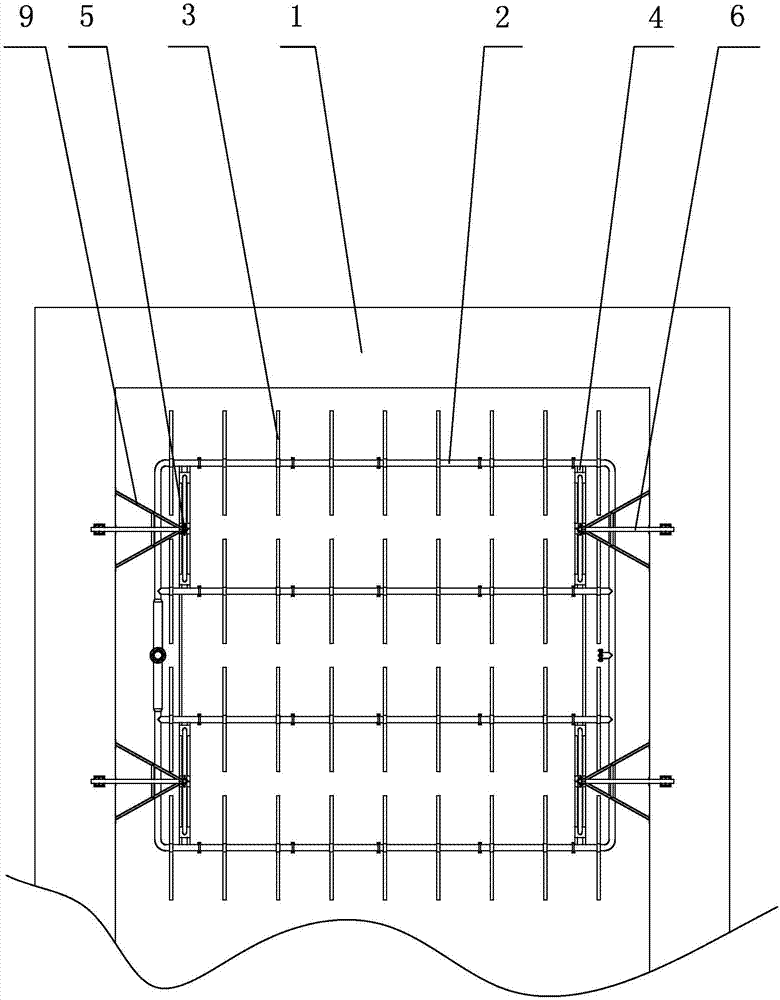

[0026] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0027] The bracket type air distribution pipe lifting device of the present invention, its technical scheme comprises the multiple groups of air distribution pipes 2 carrying the aeration pipe 3 in the aeration tank 1, the multiple groups of air distribution pipes 2 in the aeration tank 1 (such as the aeration tank 1 The length, width and height are respectively 42 meters, 10 meters in width and 6.4 meters in depth) and are arranged along the length direction of the aeration tank 1. Taking the last group of air distribution pipes 2 in the aeration tank 1 as an example, the arrangement Each branch of the trachea 2 is bound to the rectangular bracket 4 with a hoop, and the bracket 4 is settled at the bottom of the aeration tank 1. The length direction of the bracket 4 is the width direction of the aeration tank 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com