Preparation method of hollow rod-like zinc borate

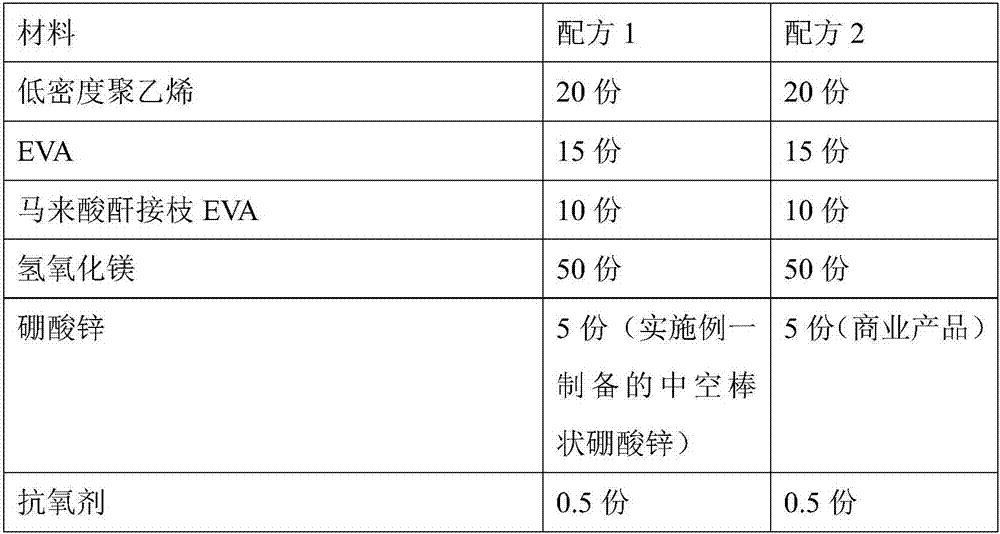

A zinc borate and rod-shaped technology, applied in the field of zinc borate preparation, can solve the problems of long reaction and aging time, poor flame retardant performance, complex zinc borate process, etc., and achieves reduced reaction time, shortened reaction time, and improved oxygen index. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

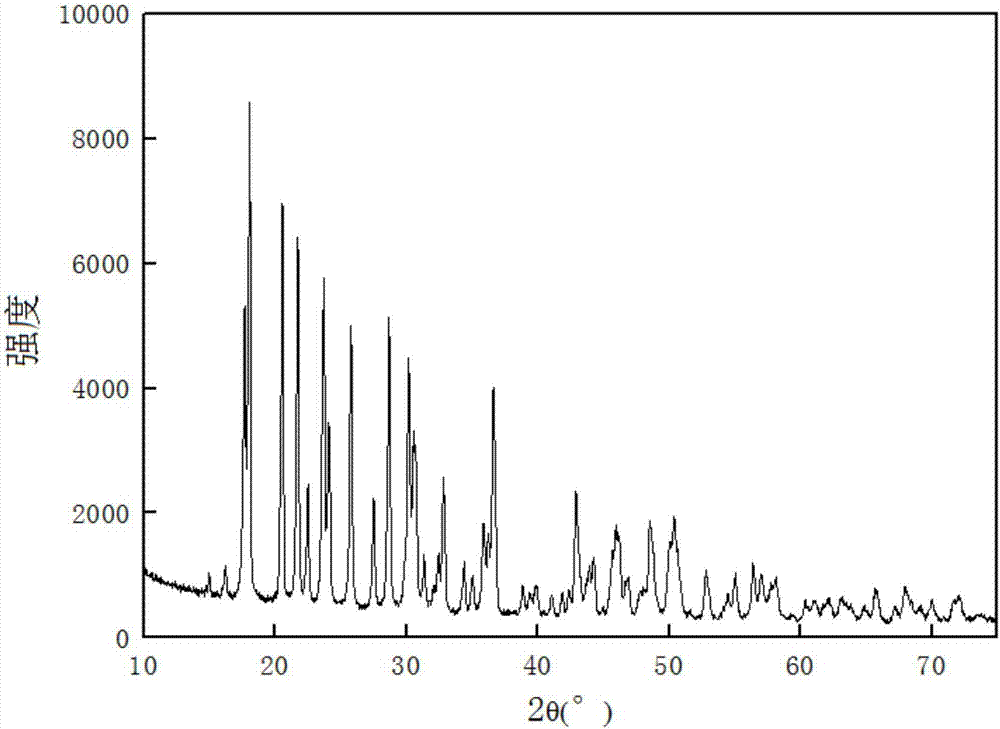

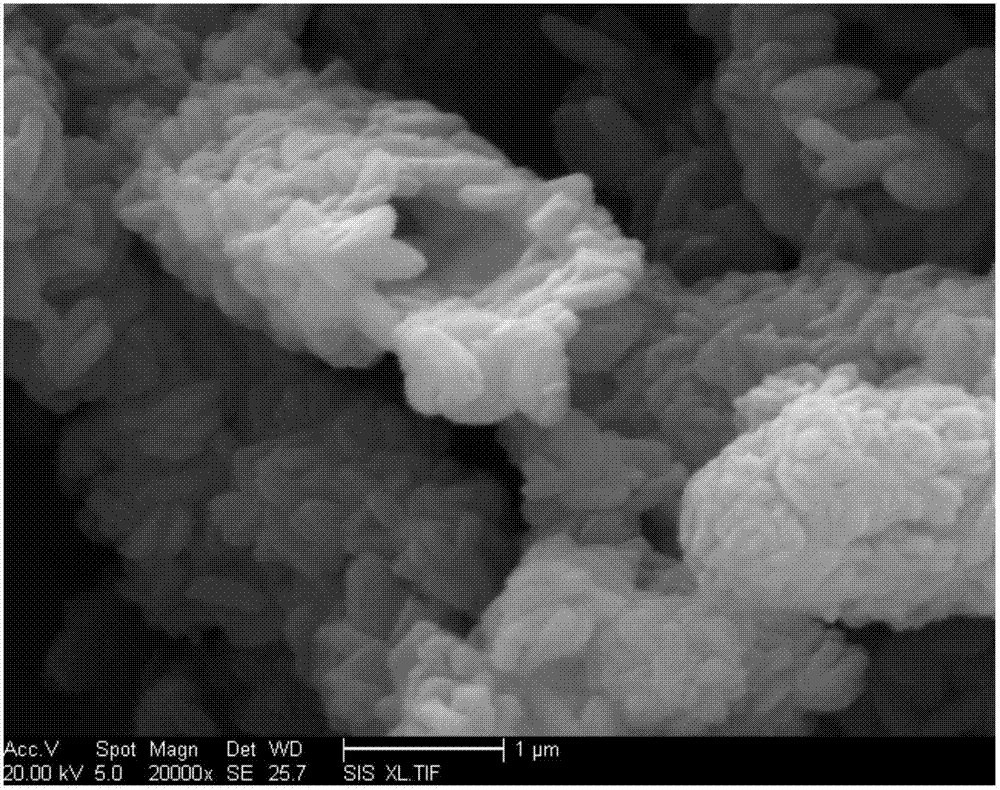

[0021] Specific implementation mode one: the present implementation mode is the preparation method of hollow rod-shaped zinc borate, specifically completes according to the following steps:

[0022] 1. Mix boric acid, zinc oxide and deionized water evenly to obtain a mixed solution;

[0023] The volume ratio of the amount of boric acid described in step 1 to deionized water is (3mol ~ 5mol): (400mL ~ 700mL);

[0024] The volume ratio of the amount of zinc oxide described in step 1 to deionized water is 1mol:(400mL~700mL);

[0025] 2. Put the mixed solution into the hydrothermal reaction kettle, then raise the temperature of the hydrothermal reaction kettle to 100℃~160℃, and then magnetically stir at the temperature of 100℃~160℃ and the stirring speed of 30r / min~60r / min React for 0.5h to 4h to obtain the reaction solution; then quickly cool the hydrothermal reaction vessel to room temperature, remove the reaction solution, and then filter to obtain the reactant; wash the react...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the rapid cooling of the hydrothermal reactor to room temperature in step 2 is performed by putting the hydrothermal reactor into a room temperature water bath for cooling. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the amount of boric acid described in step 1 to deionized water is 3.5mol:(420mL~700mL). Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Stick length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com