Online testing device and testing method used in machine tool spindle thermal error

A technology of machine tool spindle and test method, which is applied in the direction of measuring device, machine gear/transmission mechanism test, general control system, etc. many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

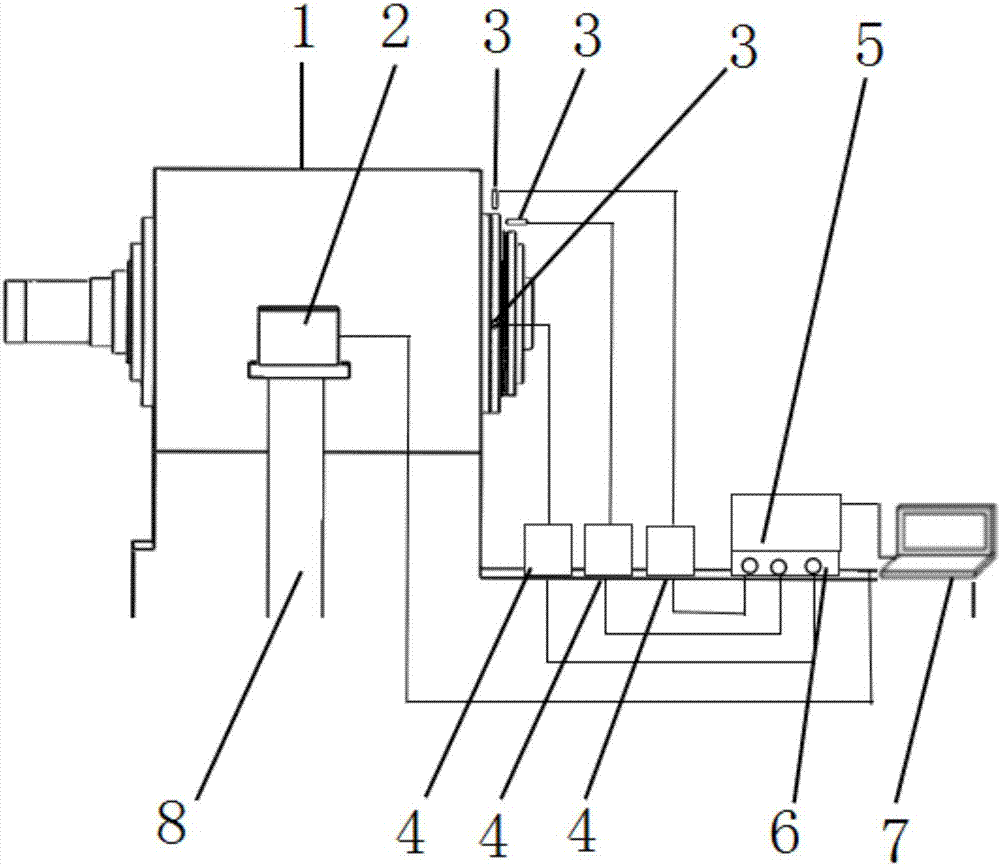

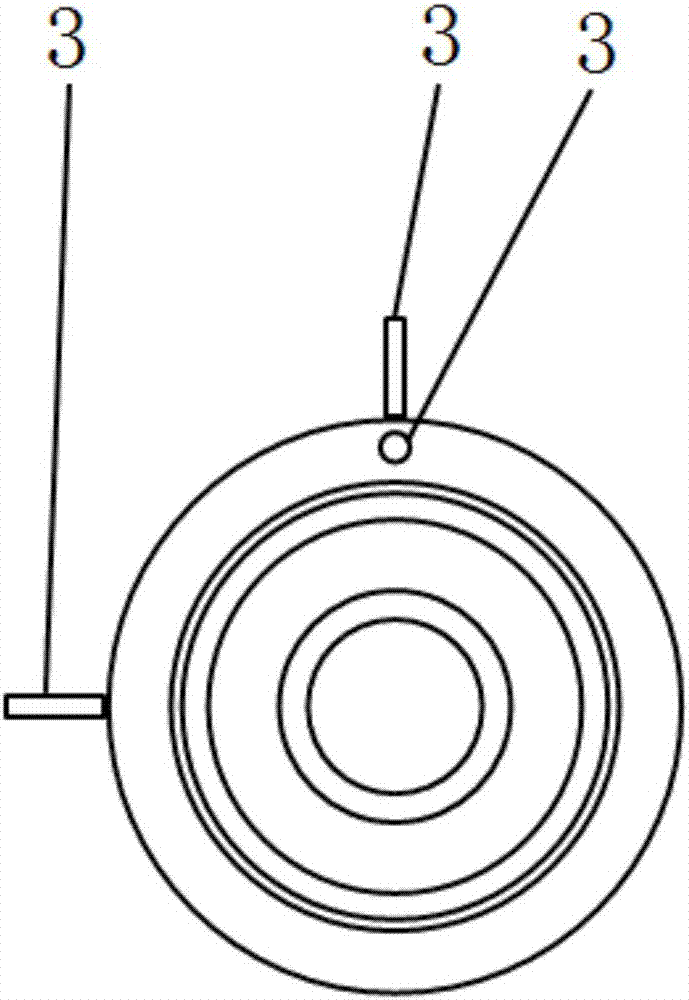

[0027] The present invention provides an on-line testing device (testing device for short, refer to Figure 1-2 ), including a thermal imager 2, an eddy current sensor 3, a sensor signal conditioner 4, a PLC 5, a PLC analog unit 6, a computer 7 and a support 8; the support 8 is placed on a horizontal plane and is positioned directly in front of the main shaft 1; The thermal imager 2 is installed on the bracket 8, and the thermal imager 2 can take a panoramic view of the main shaft 1, and collect temperature signals of temperature sensitive points on the main shaft 1 at the same time; the front end of the main shaft 1 is equipped with three eddy current sensors 3, electric The eddy current sensor 3 is used to measure the axial and two radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com