Hot-pressing composite testing method based on thermal simulation test machine

A composite test and testing machine technology, which is applied in the preparation of test samples, the application of stable tension/pressure to test the strength of materials, sampling, etc., can solve the problems of composite performance of composite test pieces, and achieve the effect of short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

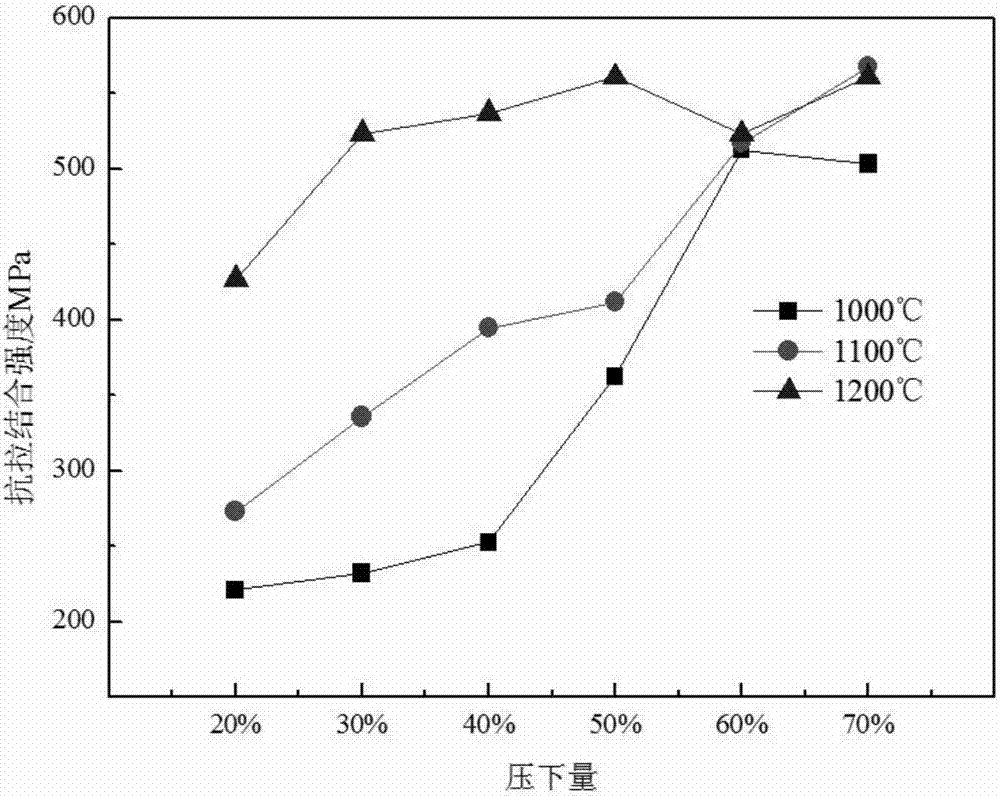

[0049] Carry out 1000℃, 20% reduction and 5s -1 Deformation rate of stainless steel / carbon steel composite test:

[0050] S1: Take stainless steel and carbon steel cylindrical specimens of φ10mm, and process the ends of the two specimens to be compounded into step shapes of φ8mm×2.4mm and φ8mm×9.6mm, so that the compression deformation can be concentrated at φ8mm; Sandpaper is used to polish the stainless steel test piece 1 and the carbon steel test piece 2 to be compounded, remove the oxide layer on the compounded surface, and clean the compounded surface with alcohol and acetone;

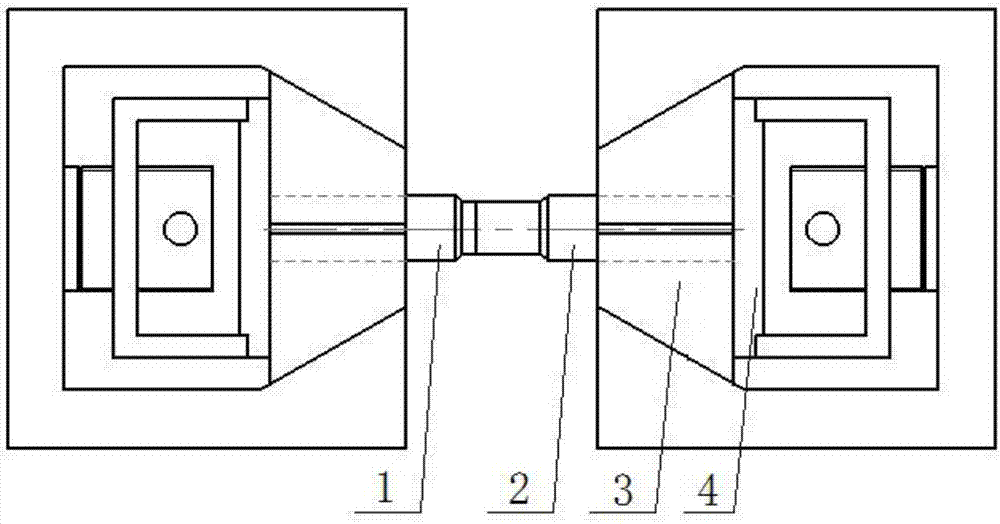

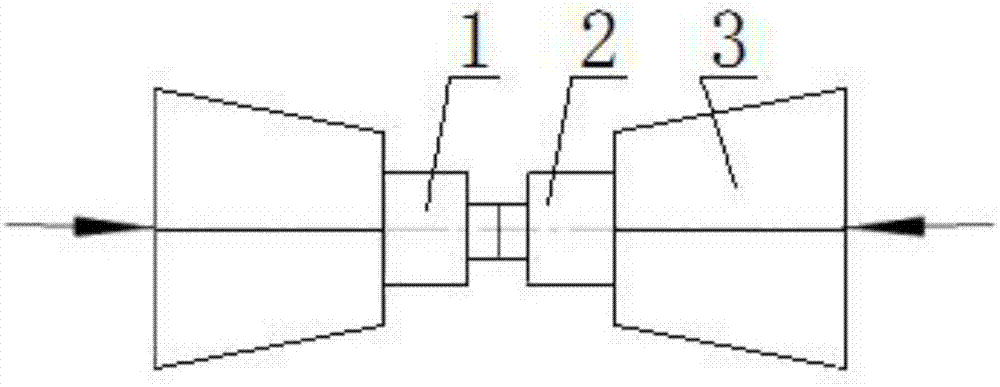

[0051] S2: if figure 1 and figure 2 As shown, the stainless steel test piece 1 and the carbon steel test piece 2 are respectively clamped on the clamping device 3, and the clamping device 3 is moved to make the surfaces to be combined of the stainless steel test piece 1 and the carbon steel test piece 2 contact each other;

[0052] S3: Heat the test piece to 1000°C, the heating rate is 10°C / s,...

Embodiment 2

[0057] 1100°C, 40% reduction and 5s -1 Deformation rate of stainless steel / carbon steel composite test:

[0058] S1: Take stainless steel and carbon steel cylindrical specimens of φ10mm, and process the ends of the two specimens to be compounded into step shapes of φ8mm×2.4mm and φ8mm×9.6mm, so that the compression deformation can be concentrated at φ8mm; Use sandpaper to polish the surface of the stainless steel specimen and the carbon steel specimen to be compounded, remove the oxide layer on the compounded surface, and clean the compounded surface with alcohol and acetone;

[0059] S2: Clamp the stainless steel test piece and the carbon steel test piece respectively on the clamping device, and move the clamping device so that the composite surfaces of the stainless steel test piece and the carbon steel test piece are in contact with each other;

[0060] S3: Heat the test piece to 1100°C, the heating rate is 10°C / s, and the holding time is 180s;

[0061] S4: Set the temper...

Embodiment 3

[0065] Carry out 1200℃, 60% reduction and 5s -1 Deformation rate of stainless steel / carbon steel composite test:

[0066] S1: Take stainless steel and carbon steel cylindrical specimens of φ10mm, and process the ends of the two specimens to be compounded into step shapes of φ8mm×2.4mm and φ8mm×9.6mm, so that the compression deformation can be concentrated at φ8mm; Use sandpaper to polish the surface of the stainless steel specimen and the carbon steel specimen to be compounded, remove the oxide layer on the compounded surface, and clean the compounded surface with alcohol and acetone;

[0067] S2: Clamp the stainless steel test piece and the carbon steel test piece respectively on the clamping device, and move the clamping device so that the composite surfaces of the stainless steel test piece and the carbon steel test piece are in contact with each other;

[0068] S3: Heat the test piece to 1200°C, the heating rate is 10°C / s, and the holding time is 180s;

[0069] S4: Set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com