Flat plate loop heat pipe-based closed chassis cooling system

A flat-panel loop and heat dissipation system technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve problems such as computer failure, development level impact, and increase user additional costs, to achieve compressed size and volume, Effect of high heat transfer capacity and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0020] This embodiment provides a closed computer heat dissipation system based on a flat-plate loop heat pipe, which changes the heat dissipation method of ventilation and heat dissipation of the traditional computer case, and adopts a flat-plate loop heat pipe heat transfer technology for high-power devices on the basis of fully sealing the computer case. To dissipate heat.

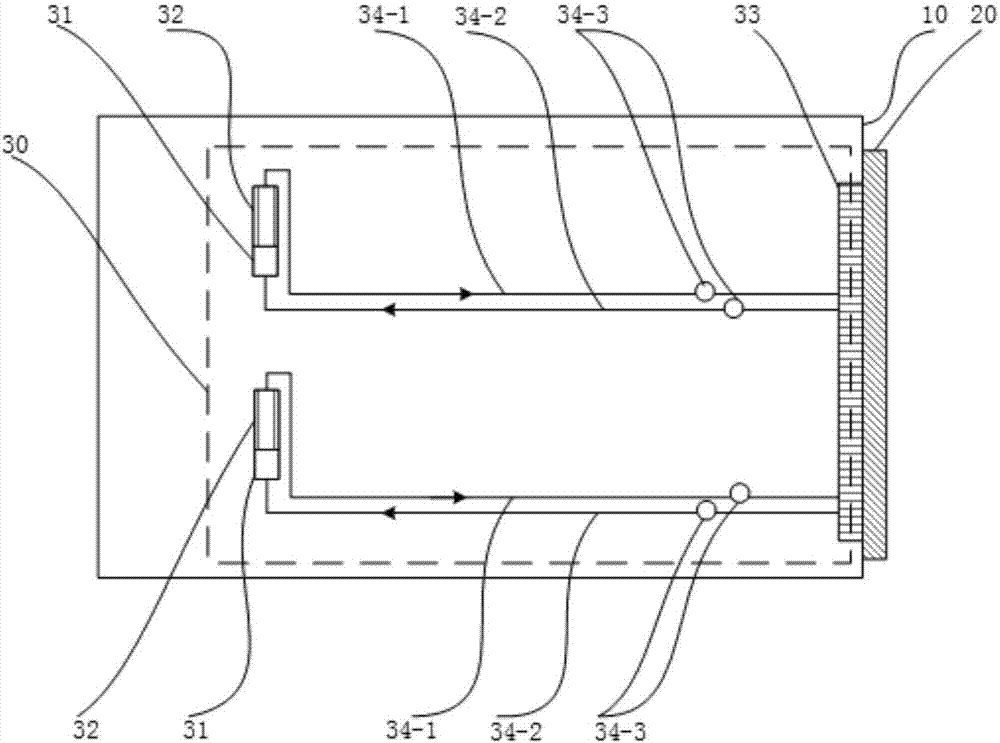

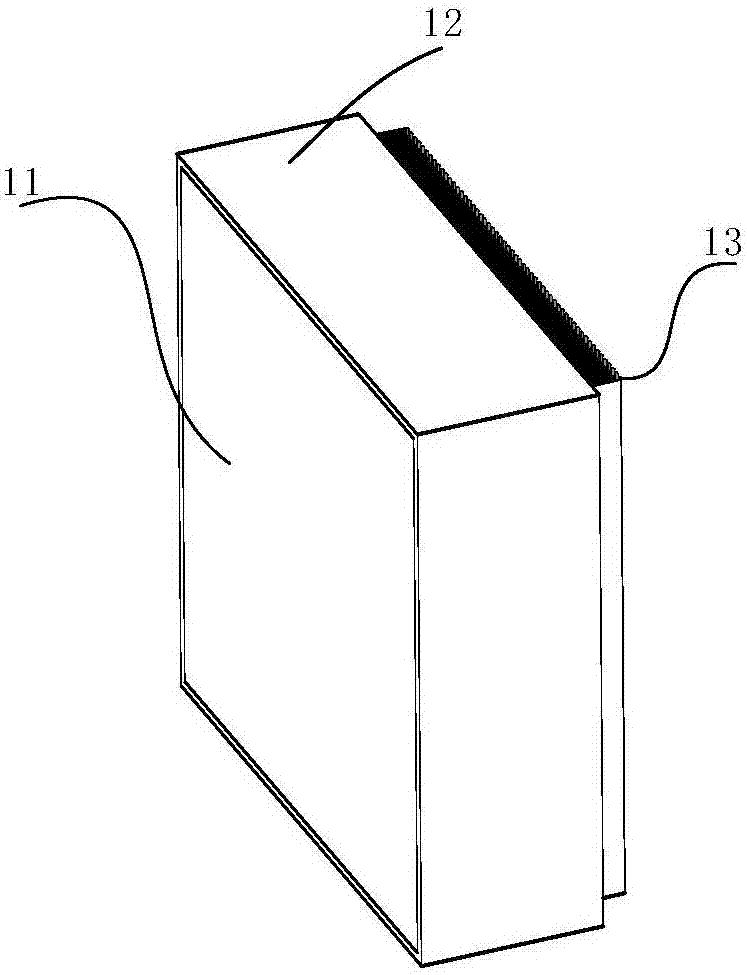

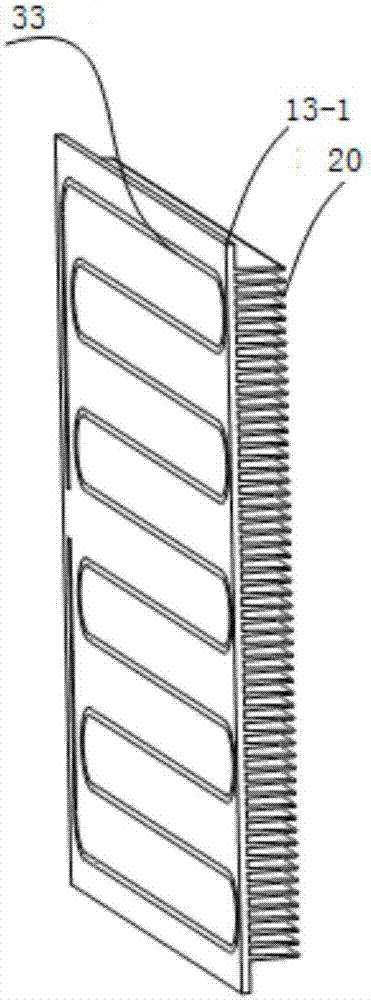

[0021] like figure 1 As shown, the fully enclosed computer heat dissipation system includes: a closed chassis 10, heat dissipation fins 20, and flat-plate loop heat pipes 30; wherein, multiple sets of flat-plate loop heat pipes 30 can be set according to the needs of heat dissipation devices, figure 1 Two sets of flat loop heat pipes 30 are arranged in the enclosed cabinet 10 shown.

[0022] The closed chassis 10 is equipped with a flat-plate loop heat pipe 30 inside and a cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com