A kind of medium and high strength aluminum alloy seamless pipe extrusion process method

A process method and aluminum alloy technology, which is applied in the field of aluminum alloy extrusion, can solve the problems of lower production efficiency and success rate, difficulty in guaranteeing the dimensional accuracy of finished products, and high deformation resistance of aluminum alloy, so as to improve production efficiency, surface quality, The effect of uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The medium and high strength seamless pipe extrusion process of the present invention includes heating the billet → heating the mold → rapid thermal piercing by using a piercing head → lubricating the follower needle to extrude the pipe.

[0025] Bar heating: place the solid bar in a heating furnace, heat the billet to the normal hot extrusion temperature of the aluminum alloy through a resistance furnace or other heating furnace, and keep it warm for 4 to 6 hours; heat the extrusion cylinder to 400~450°C and maintain the temperature.

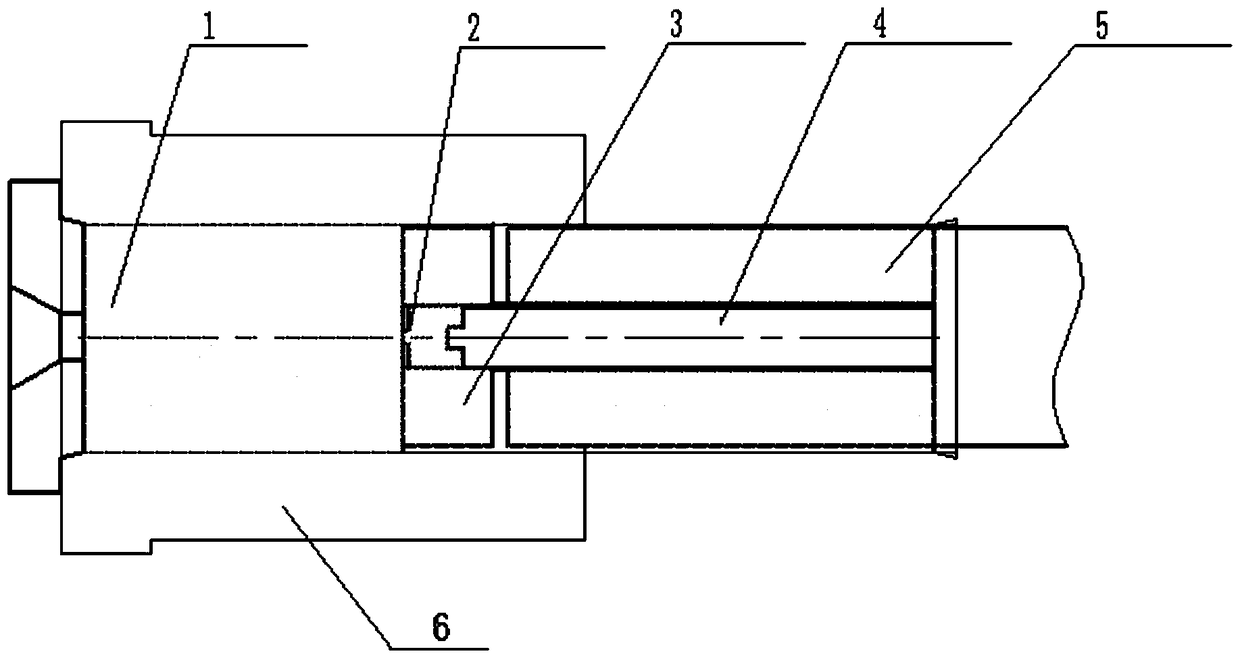

[0026] Die heating: the extrusion die (including the extrusion barrel 6), the extrusion needle 4 and the piercing head 2 and other molds are placed in a mold heating furnace and heated to 400-500°C.

[0027] High-speed extrusion of the piercing head: such as figure 1 As shown, the preheated piercing head 2 is matched with the extrusion pad 3. After the billet 1 and the extrusion pad 3 enter the extrusion cylinder 6, the thread is taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com