Production process of 7075 aluminum alloy seamless tube

A production process and aluminum alloy technology, which is applied in the field of aluminum alloy manufacturing, can solve the problems of difficult process control, large pipe size deviation, and large friction force, and achieve the effects of reducing effective contact area, ensuring quality, and reducing friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

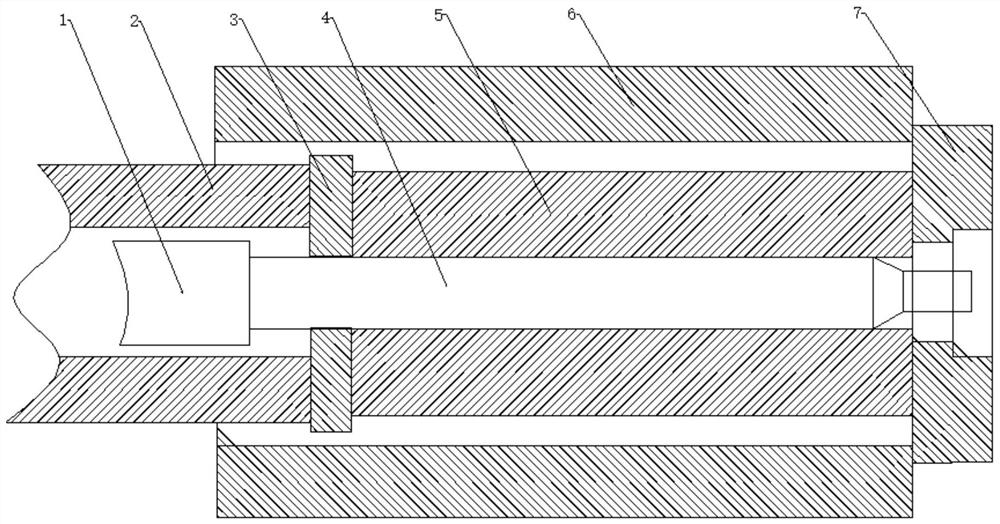

Image

Examples

Embodiment 1

[0029] A kind of production technology of 7075 aluminum alloy seamless pipe, comprises the following steps:

[0030] A. Ingredients: The aluminum alloy raw materials for preparing aluminum alloy seamless pipes are mixed according to weight percentage, namely: Si: 0.06%, Fe: 0.13%, Cu: 1.57%, Mn: 0.02%, Mg: 2.72%, Cr: 0.19%, Zn: 5.36%, Ti: 0.03%, Zr: 0.007%, single impurity ≤ 0.05%, total ≤ 0.15%, the balance is Al;

[0031] B. Melting and casting: Put the prepared aluminum alloy raw materials in a melting furnace to melt into liquid aluminum alloy at a melting temperature of 720-750°C. During the melting process, turn on electromagnetic stirring and remove slag, and then pour the melted aluminum alloy into Refining in a refining furnace with a refining temperature of 710-750°C, using Cl-Ar mixed gas for refining and slag removal to obtain aluminum alloy solid ingots;

[0032] C. Homogenization: The aluminum alloy ingot is subjected to homogenization heat treatment in a homogeni...

Embodiment 2

[0038] The difference between Example 2 and Example 1 is that in step A, the aluminum alloy raw materials for preparing aluminum alloy seamless pipes are mixed according to weight percentage, namely: Si: 0.06%, Fe: 0.13%, Cu: 1.55%, Mn: 0.02%, Mg: 2.62%, Cr: 0.19%, Zn: 5.36%, Ti: 0.03%, Zr: 0.007%, single impurity ≤ 0.05%, total ≤ 0.15%, the balance is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com