Precision instrument polishing equipment

A technology of precision instruments and equipment, applied in the field of precision instruments, can solve the problems of unsatisfactory precision requirements, poor polishing quality, poor rigidity of polishing knives, etc., and achieve the effects of low production cost, convenient and fast polishing, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

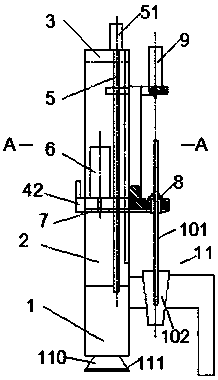

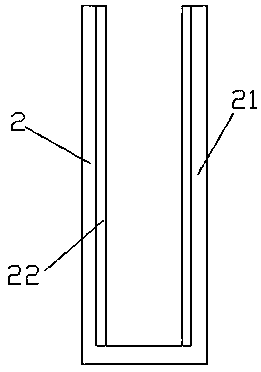

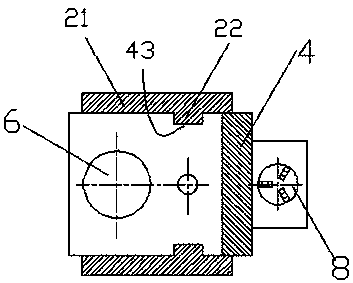

[0022] Such as Figure 1-Figure 7 As shown, a kind of precision instrument polishing equipment of the present invention comprises machine base 1, vertical rod 2, support plate 3, work frame 4, moving device, first rotating power device, instrument fixing device and polishing knife 11, described The vertical rod 2 is fixedly arranged on the left side of the upper surface of the machine base 1, the vertical rod 2 includes side plates 21 arranged front and back, the support plate 3 is fixed on the upper end of the vertical rod 2, and on the side The inner side of the plate 21 is provided with a slide rail protruding bar 22 extending in the up and down direction, the left part of the work frame 4 is arranged between the side plates 21 arranged front and back, and the moving device includes an up and down moving device 51 and a lead screw 5. The up and down movement device 51 is fixed above the support plate 3, and the conduction shaft of the up and down movement device 51 runs thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com