Glass fiber reinforced plastic pipeline winding system and method

A technology of glass fiber reinforced plastics and pipes, which is applied in the direction of tubular objects, household appliances, and other household appliances, which can solve problems such as inconvenience and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

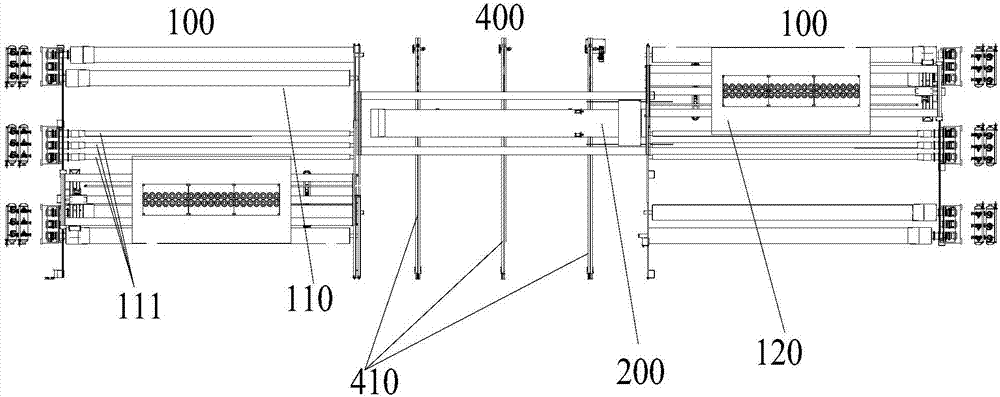

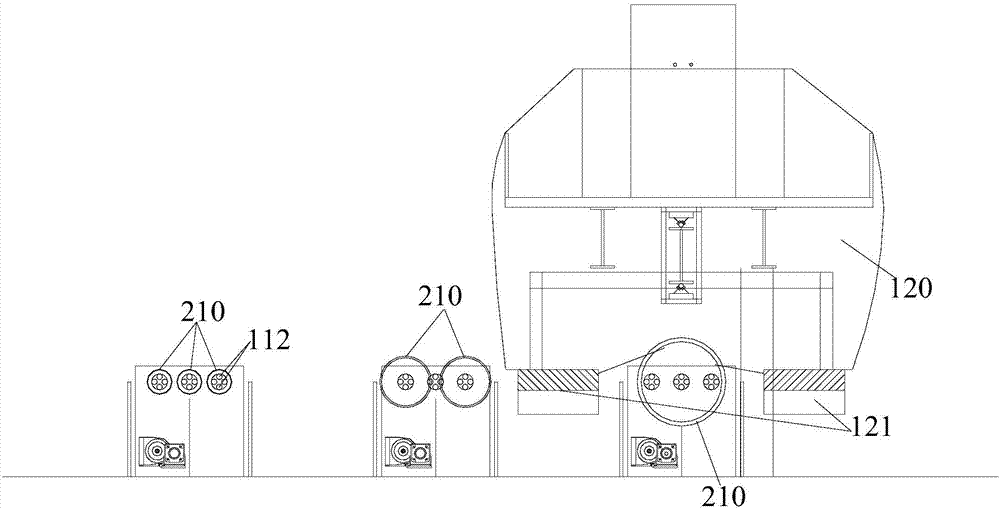

[0028] Please refer to figure 1 , the present invention provides a FRP pipe winding system, comprising two symmetrically arranged FRP winding units 100 and a demoulding unit 400 located between the two FRP winding units 100, the FRP winding unit 100 includes several sets of winding Shafts 110 , each set of winding shafts 110 is provided with at least three symmetrically distributed mandrels 111 , and each mandrel 111 has the same diameter and is less than 150 mm. In this example, please refer to figure 1 , each winding shaft 110 is provided with three mandrels 111, and the distance between each mandrel 111 is generally less than or equal to 50 mm.

[0029] The FRP winding unit 100 provided by the present invention is arranged under the vehicle frame, and a moving track (not shown) is arranged on the vehicle frame. The first orbit and the second orbit parallel to the radial direction of the mandrel 111 are perpendicular to each other. Generally, the number of first orbits is ...

Embodiment 2

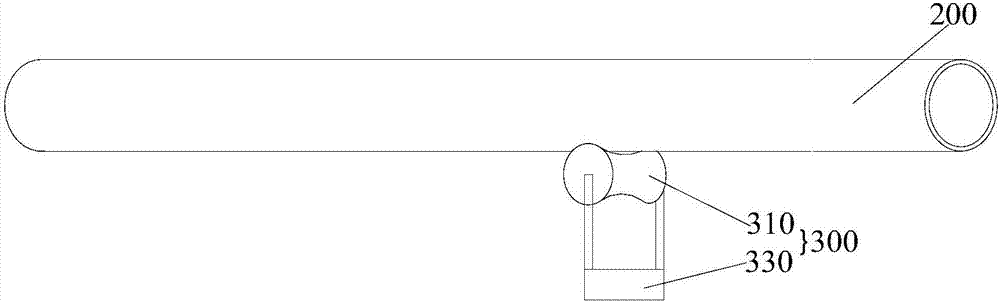

[0041] Please refer to Figure 4 The difference between this embodiment and Embodiment 1 is that the auxiliary demoulding device 300 is a conveying chain 320, the outer surface of the conveying chain 320 is spliced to form a rolling surface matching the outer surface of the FRP pipe 200, and the rolling direction of the conveying chain 320 is the same Facing the demoulding direction, a lifting rod device 330 is also provided below the conveying chain 320 for adjusting the height of the conveying chain 320 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com