Slitting and marking device for paper towel folding machine

A marking device and folding machine technology, applied in the direction of folding thin materials, transporting and packaging, sending objects, etc., can solve the problems of inability to use slitting and folding machines, pigment contamination of products, low production efficiency, etc., to reduce defective products, difficult The effect of pollution and high dosing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

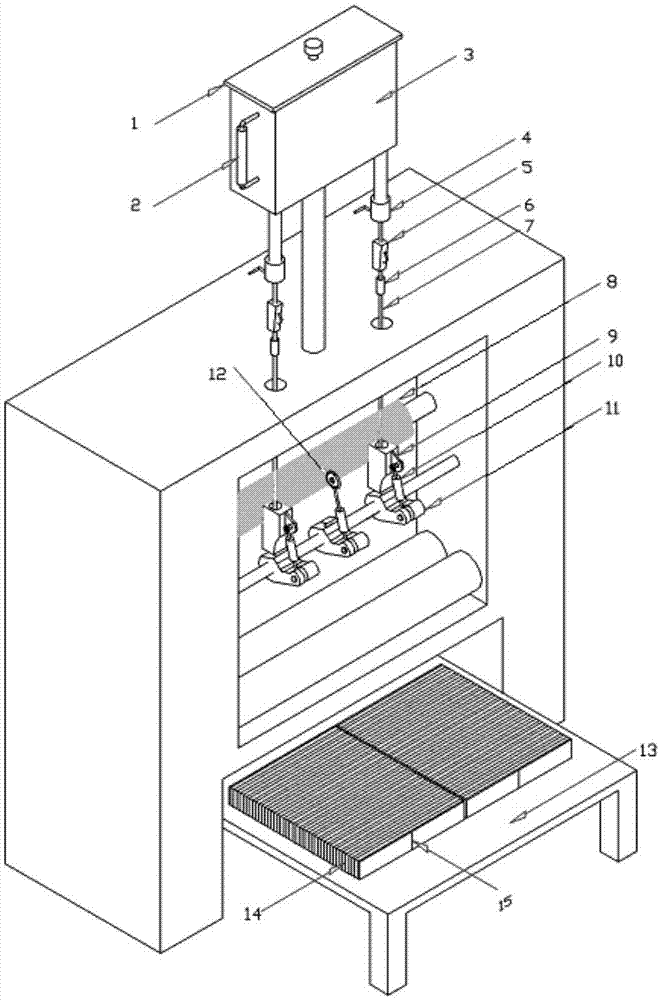

[0025] A paper towel folding machine slitting and marking device, its structure is as follows figure 1 As shown, it mainly includes a pigment marking assembly, a cylinder 10 and a cutting knife 12. The paint marking assembly includes a paint container 3 and a paint marker 9 connected to the paint container 3 through a paint pipeline 7 , and a flow control unit is arranged on the paint pipeline 7 .

[0026] A paint container cover 1 is provided on the paint container 3 to place paint splashes, and a liquid level tube 2 is provided on the side of the paint container 3 for observing the use of paint in the paint container 3 . The quantity of the paint markers 9 is set as required, and each paint marker 9 communicates with the paint container 3 through the paint pipeline 7 . The flow control unit includes a valve 4, a flow control valve 5 and a flow rate observation tube 6. The pigment is automatically added through the control of the valve 4. According to the speed of the foldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com