Composite corrosion inhibitor for aqueous cutting fluid, preparation method of the corrosion inhibitor, and the aqueous cutting fluid

A composite corrosion inhibitor and cutting fluid technology, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of high cost, unsatisfactory aluminum alloy protection effect, etc., achieve reduced additive amount, excellent protection performance, and reduced cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

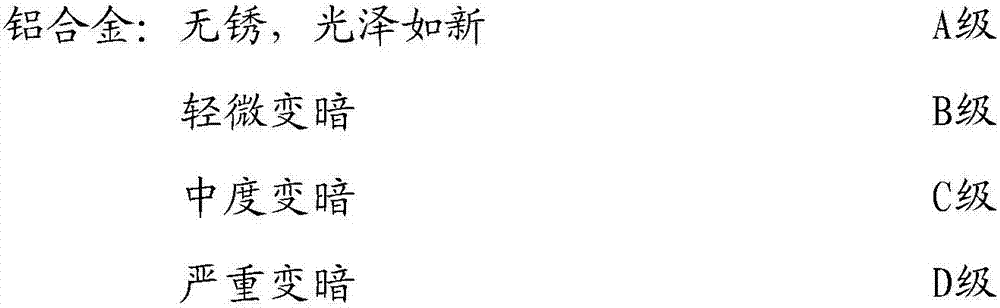

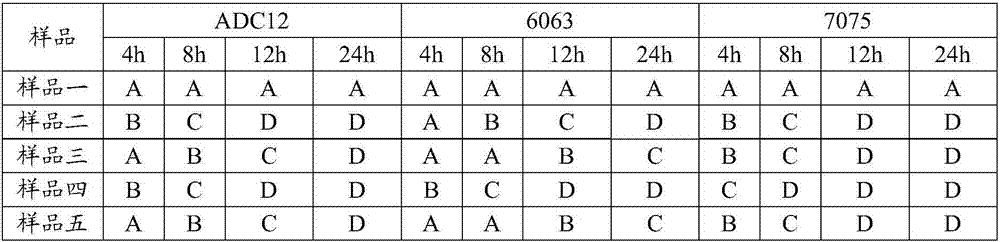

[0045] Take an ordinary water-based cutting fluid A, sample 1: add 0.5% aluminum corrosion inhibitor compound package 1 to water-based cutting fluid A, stir evenly; sample 2: add 0.5% ASI80 to water-based cutting fluid A, stir uniform. Sample 3: Add 0.6% to water-based cutting fluid A CP-NF-3, stir well; sample 4: add 0.3% ASI80 and 0.2% C101 to water-based cutting fluid A, stir well. Sample 5: Take 20.00% of ASI80, 26.67% of AR-80, and 53.33% of C101 and stir evenly to obtain Aluminum Corrosion Inhibitor Compound Package II. Add 0.5% Aluminum Corrosion Inhibitor Compound Package II to water-based cutting fluid A; Sample Five: Take 26.67% of ASI80, 53.33% of Lubrhophos LB-400, 20.00% of CP-NF-3 was stirred evenly to obtain the aluminum corrosion inhibition compound package III, and 0.5% aluminum corrosion inhibition compound package III was added to the water-based cutting fluid A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com