A kind of manufacturing process of sponge titanium with low impurity content

A production process and impurity content technology, applied in the field of sponge titanium production process, can solve the problems of increasing the impurity content of the product, affecting the reaction speed, reducing the yield of the finished product, etc., so as to reduce the impurity content of the product, change the appearance and color, and improve the quality of the product. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

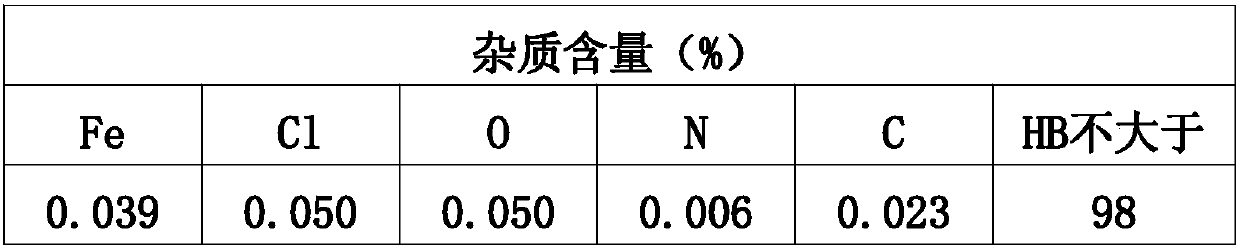

Embodiment 1

[0034] A manufacturing process of titanium sponge with low impurity content, comprising the following steps:

[0035] (1) After titanium slag and petroleum coke are mixed in a weight ratio of 7:1, they are suspended in sodium chloride molten salt, and chlorine gas is introduced to obtain crude titanium tetrachloride;

[0036] (2) The crude titanium tetrachloride is centrifuged at a speed of 1000r / min to obtain liquid phase crude titanium tetrachloride and solid phase residue. The liquid phase crude titanium tetrachloride is kept at 136-145°C and 0-5kPa Vanadium is removed by distillation, and the distillate of vanadium is removed by rectification at 136-145 ° C and 1kPa to remove silicon; the bottom distillate of the rectification equipment is collected, that is, refined titanium tetrachloride; in the step (2) , the weight ratio of metal magnesium, magnesium chloride and titanium tetrachloride is 10:1:23;

[0037] (3) Put magnesium metal into the reactor, and cover the magnes...

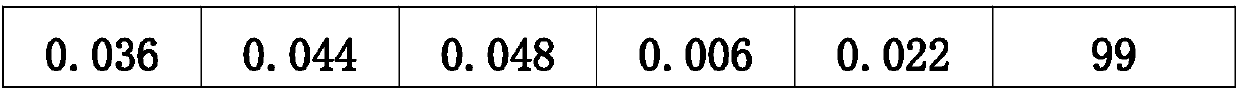

Embodiment 2

[0039] A manufacturing process of titanium sponge with low impurity content, comprising the following steps:

[0040] (1) After titanium slag and petroleum coke are mixed in a weight ratio of 8:1, they are suspended in sodium chloride molten salt, and chlorine gas is introduced to obtain crude titanium tetrachloride;

[0041] (2) The crude titanium tetrachloride is centrifuged at a speed of 1200r / min to obtain liquid phase crude titanium tetrachloride and solid phase residue, and the liquid phase crude titanium tetrachloride is kept at 136-145°C and 0-5kPa Vanadium is removed by distillation, and the distillate of vanadium is removed by rectification at 136-145 ° C and 1kPa to remove silicon; the bottom distillate of the rectification equipment is collected, that is, refined titanium tetrachloride; in the step (2) , the weight ratio of metal magnesium, magnesium chloride and titanium tetrachloride is 10:0.8:23;

[0042] (3) Put the metal magnesium into the reactor, and cover ...

Embodiment 3

[0044] A manufacturing process of titanium sponge with low impurity content, comprising the following steps:

[0045] (1) After mixing titanium slag and petroleum coke in a weight ratio of 6:1, suspending in sodium chloride molten salt, feeding chlorine gas to obtain crude titanium tetrachloride;

[0046] (2) The crude titanium tetrachloride is centrifuged at a speed of 800r / min to obtain liquid phase crude titanium tetrachloride and solid phase residue. The liquid phase crude titanium tetrachloride is kept at 136-145°C and 0-5kPa Vanadium is removed by distillation, and the distillate of vanadium is removed by rectification at 136-145 ° C and 1kPa to remove silicon; the bottom distillate of the rectification equipment is collected, that is, refined titanium tetrachloride; in the step (2) , the weight ratio of metal magnesium, magnesium chloride and titanium tetrachloride is 10:1.2:23;

[0047] (3) Put magnesium metal into the reactor, and cover the magnesium chloride particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com