Adjustable pressure gas pressure reduction device and method

A technology of pressure gas and decompression device, applied in the field of decompression, can solve the problems of decompression and outlet pressure fluctuation, inconvenient maintenance and high production cost, and achieve stable decompression and outlet pressure, good environmental adaptability and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

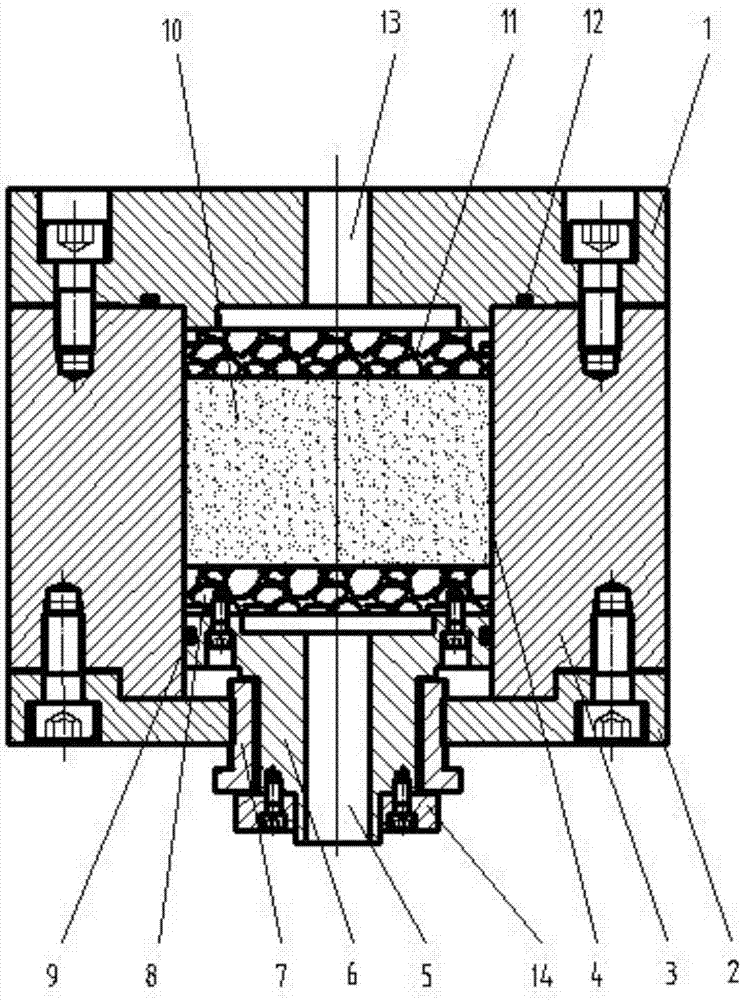

[0028] like figure 1 shown. The invention discloses an adjustable pressure gas decompression device, comprising a valve body 3 with a valve cavity 4, the inlet head 1 of the valve cavity 4 is sealed and connected with the upper end surface of the valve body 3 through bolts, the valve cavity 4 The lower head 2 is sealed and connected with the lower end surface of the valve body 3 through bolts;

[0029] In the valve cavity 4, an air intake and air permeable steel layer 11 and an exhaust air permeable steel layer 8 are placed in sequence according to the direction of air flow, and a fine sand layer 10 is filled between the air intake and air permeable steel layer 11 and the exhaust air permeable steel layer 8;

[0030] The lower head 2 is provided with an adjustable valve assembly for providing the exhaust air-permeable steel layer 8 to move in the direction of the air-intake air-permeable steel layer 11, so as to extrude and fill the air-intake air-permeable steel layer 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com