Evaluation method of anti-skid performance of coarse aggregate based on AIMS aggregate imaging system

An imaging system and anti-skid performance technology, applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the disadvantages of not effectively reflecting the surface characteristics of coarse aggregate and the pros and cons of skid resistance, and the design and improvement of asphalt pavement skid resistance impact, large variability of coarse aggregate grinding value measurement results, etc., to achieve excellent long-term anti-skid performance, scientific and reasonable evaluation methods, and intuitive evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The anti-skid performance evaluation method of AIMS-based diorite A and diorite B in this embodiment comprises the following steps:

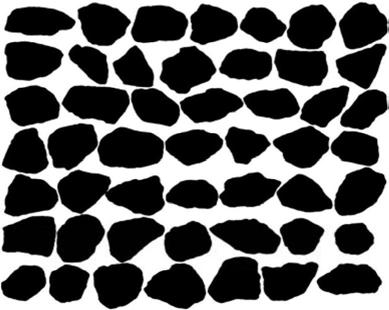

[0031] Use the AIMS aggregate imaging system to scan the images of the diorite A and B, measure and calculate the angularity index Ai of the coarse aggregate by using its own data processing system; the diorite A and B in this embodiment are before the scanning measurement , it should be cleaned first to remove dust and other impurities, so as not to interfere with the scanning results. Scan results see figure 1 and figure 2 , and the measurement data are shown in Table 1.

[0032] Table 1 Angular AIMS measurement results of diorite A and B

[0033] sample Particle size (mm) Ai(mm) Diorite A 4.75 2709.6 Diorite A 9.5 2697.8 Diorite B 4.75 2852.7 Diorite B 9.5 2593.2

[0034] Utilize AIMS aggregate material imaging system, carry out image scanning to diorite A, B, adopt wavelet method to m...

Embodiment 2

[0046] The present embodiment is based on the skid resistance evaluation method of the diabase of AIMS, limestone and comprises the following steps:

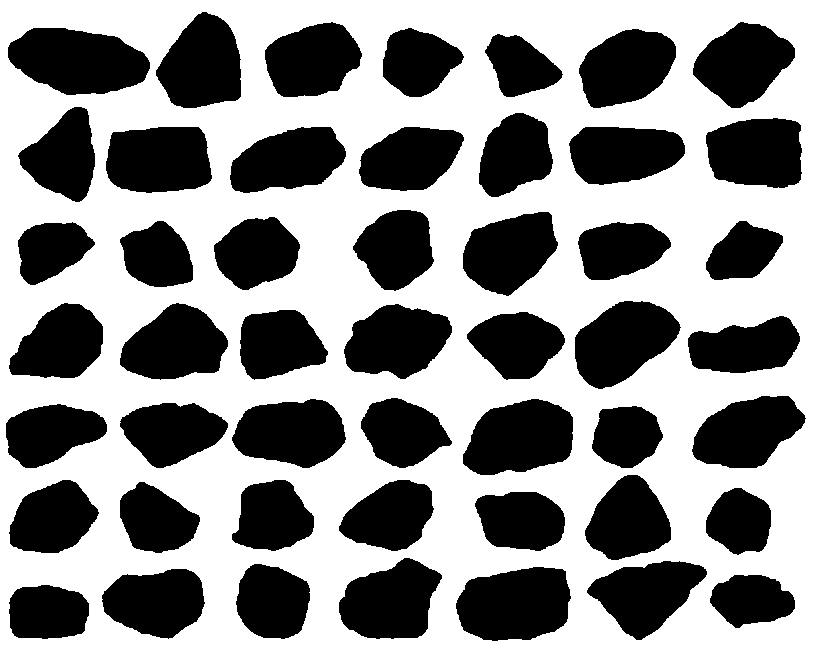

[0047](1) Utilize the AIMS aggregate imaging system to scan the image of diabase and limestone, measure and calculate the angularity index Ai of the coarse aggregate; before the diabase and limestone in the present embodiment are scanned and measured, they should be Perform a wash to remove impurities such as dust that could interfere with your scan results. scan result Figure 5 and Figure 6 , the measured data are shown in Table 5.

[0048] Table 5 Angular AIMS measurement results of diabase and limestone

[0049] sample Particle size (mm) Ai(mm) Diabase 4.75 2699.9 Diabase 9.5 2701.4 limestone 4.75 3092.1 limestone 9.5 2938.8

[0050] (2) Utilize AIMS aggregate material imaging system, image scanning is carried out to diabase, limestone, adopt wavelet method to measure and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com