Wedged embedded binder clip loading and unloading device

A long tail clip and embedded technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of reduced precision, wear, and difficult control of cylinder speed, so as to promote production efficiency, improve operation efficiency, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

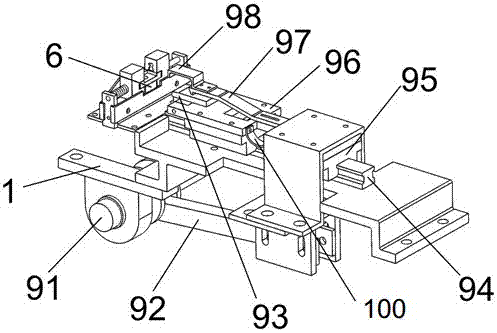

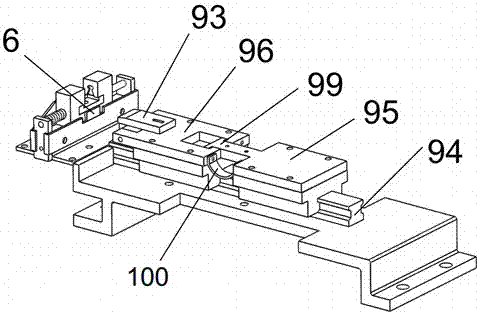

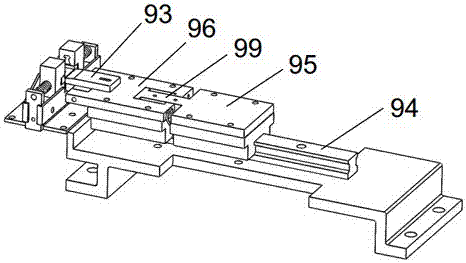

[0024] With reference to the accompanying drawings, the wedge-shaped embedded long tail clip loading and unloading device includes a frame 1, a convex bottom platform 8 is fixed on the frame, and left and right stoppers 11, 12, front and rear baffles are fixed on the convex bottom platform. Left and right slide blocks 21,22 are arranged in the slideway that left and right stoppers and front and rear baffle plates 7 form, and the inboard side of left and right slide blocks is provided with groove 25 consistent with long tail folder shape, slide block side perforation; Spring guide rod 3. One end is fixed with the stopper, and the other end is inserted into the opening 23 on the side of the slider. The spring guide rod is covered with a spring 4; the clip body base 5 is clamped between the left and right sliders, and the two sides of the clip body base are embedded in the gaps of the left and right sliders. The lower end of the clamp body base is provided with a limit block, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com