Positioning and clamping equipment having air detection function, arranged on four-axis machine tool and used for compressor cylinder finish machining

A technology of compressor cylinder block and clamping equipment, applied in metal processing equipment, positioning device, measuring/indicating equipment, etc., can solve the problems of difficult three-sided processing, inability to guarantee processing accuracy, and easy deformation of workpieces, etc. Achieve the effect of improving accuracy, simple structure and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

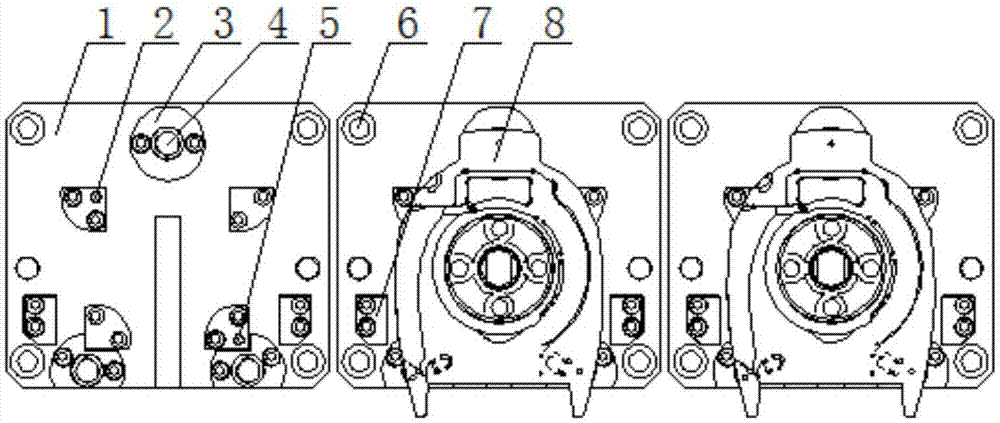

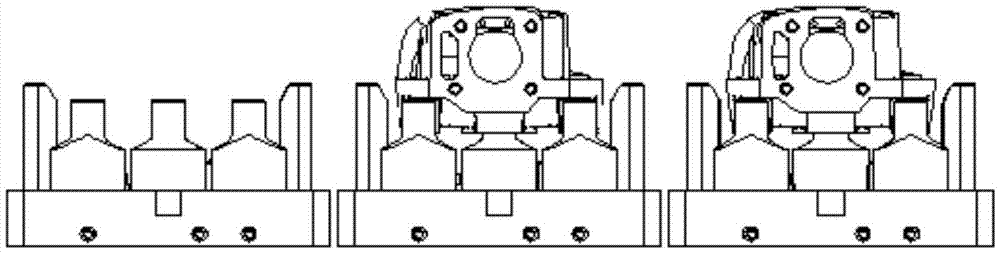

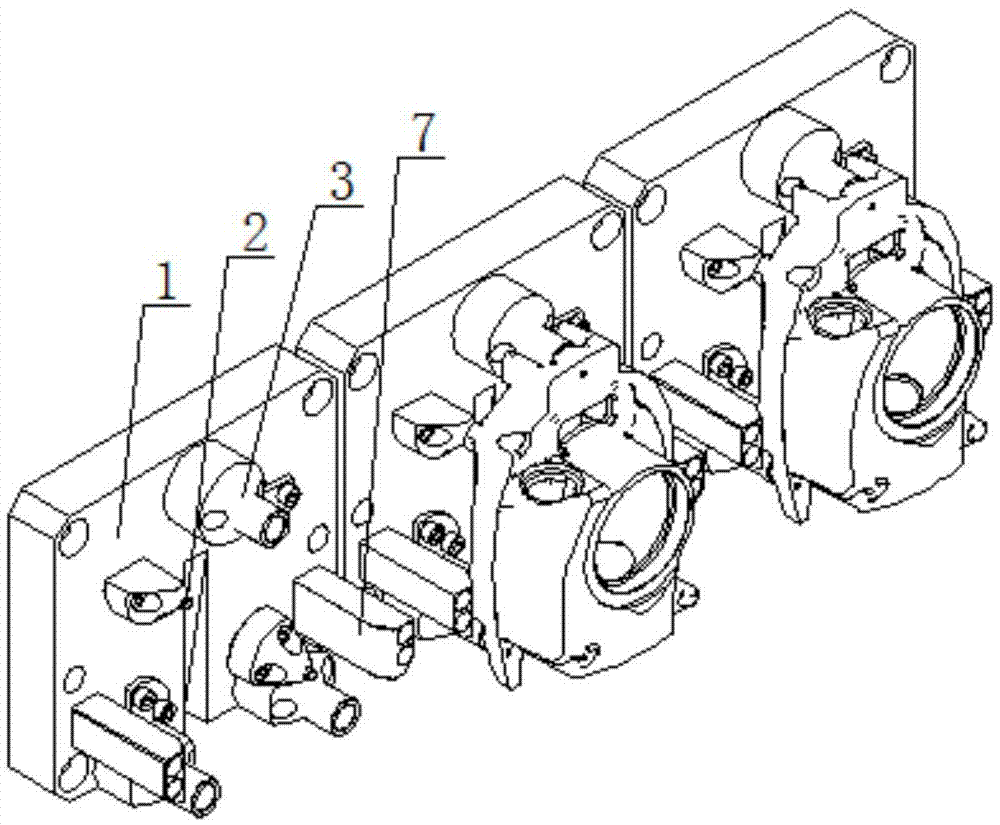

[0018] A pneumatic inspection, positioning and clamping device for the four-axis machine tool finishing of a compressor cylinder block, including a plurality of clamp units, the number of which is not limited, three in this embodiment. Each fixture unit is made of main board 1, air detection support sleeve 3, installation guide block 7 and positioning pins, and mounting holes 6 are made on the four corners of the main board, so as to be installed on the four-axis machine tool. There are three gas detection support sleeves, one of which is installed in the middle of the upper front of the main board, and the other two are symmetrically installed on the left and right sides of the lower front of the main board. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com