Zipper dyeing cylinder balanced bobbin creel

A creel and dyeing vat technology, applied in the field of zipper dyeing vat balancing creel, can solve the problems of potential safety hazards, waste of dyes and wastewater treatment volume, and achieve the effects of preventing color differences, reducing the amount of water and dyes, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

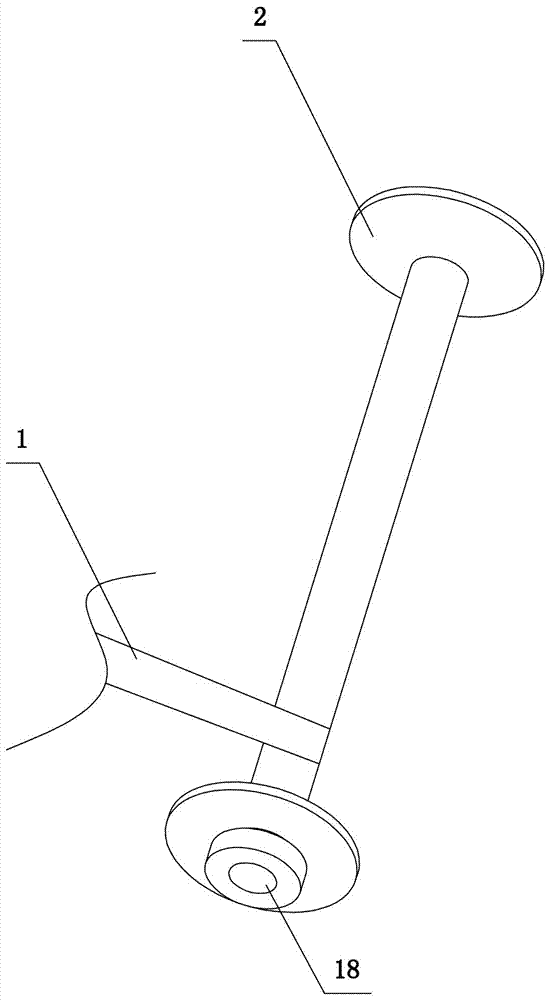

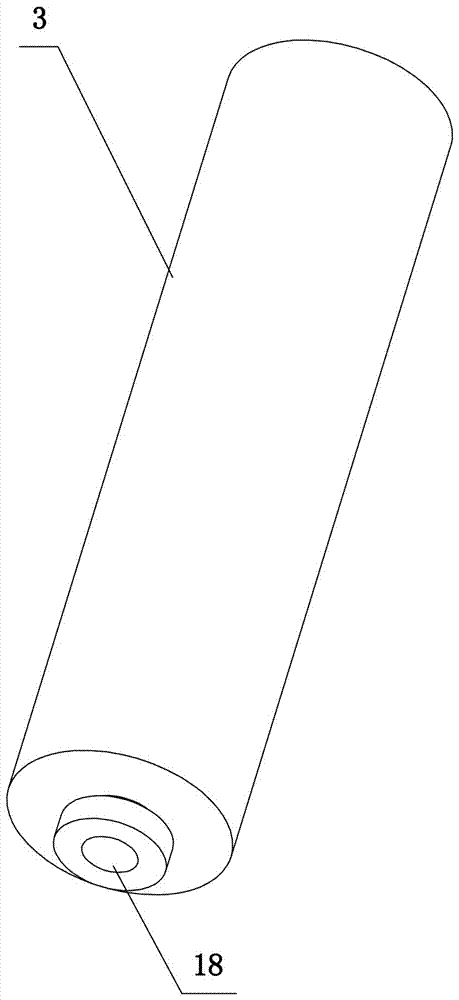

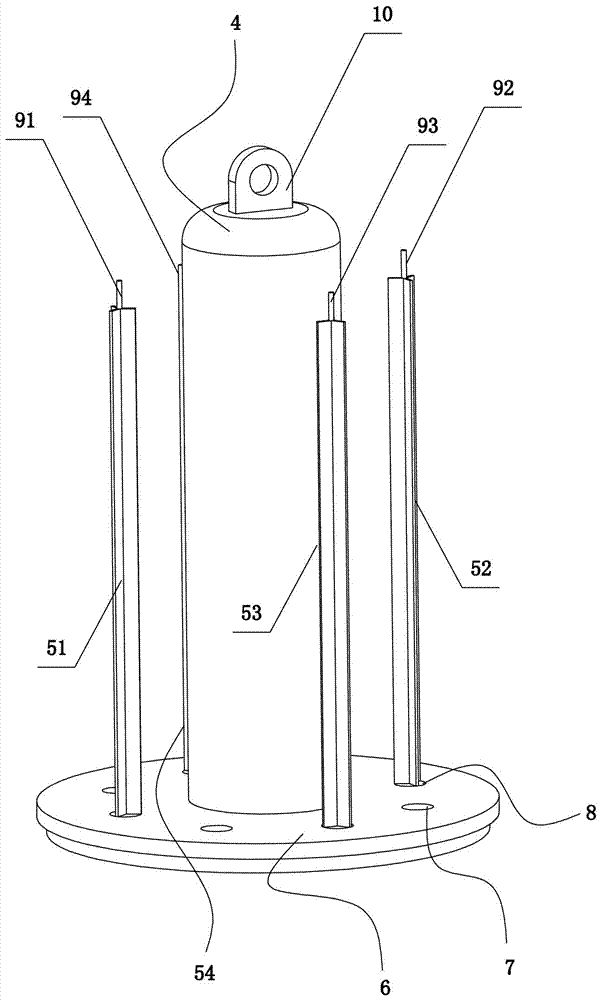

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 . A zipper dyeing vat balancing bobbin holder, comprising a base 6 and a center pillar 4 arranged on the base 6, a winding mechanism is arranged in an array around the center pillar 4, and a winding unit 1 is wound on the winding mechanism 3, The wrapping mechanism 3 is arranged vertically on the base 6 , and a hoisting part 10 is arranged on the top of the central pillar 4 . The winding attachment mechanism 3 includes a rolling cage 2 and a first opening 18 located in the middle of the rolling cage 2 and a mounting column 51 inserted in the first opening 18, a mounting column 52, a mounting column 53 and Installing column 54, described installing column 51, installing column 52, installing column 53 and one end of installing column 54 are connected with described base 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com