Hydraulic compaction device and hydraulic compaction machine

A tamping device and hydraulic technology, applied in the direction of road and soil protection, road repair, etc., can solve the problems of piston rod and tamper damage, high replacement frequency and cost, and unfavorable long-term use of hydraulic tamper, so as to reduce maintenance costs. , impact mitigation, small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

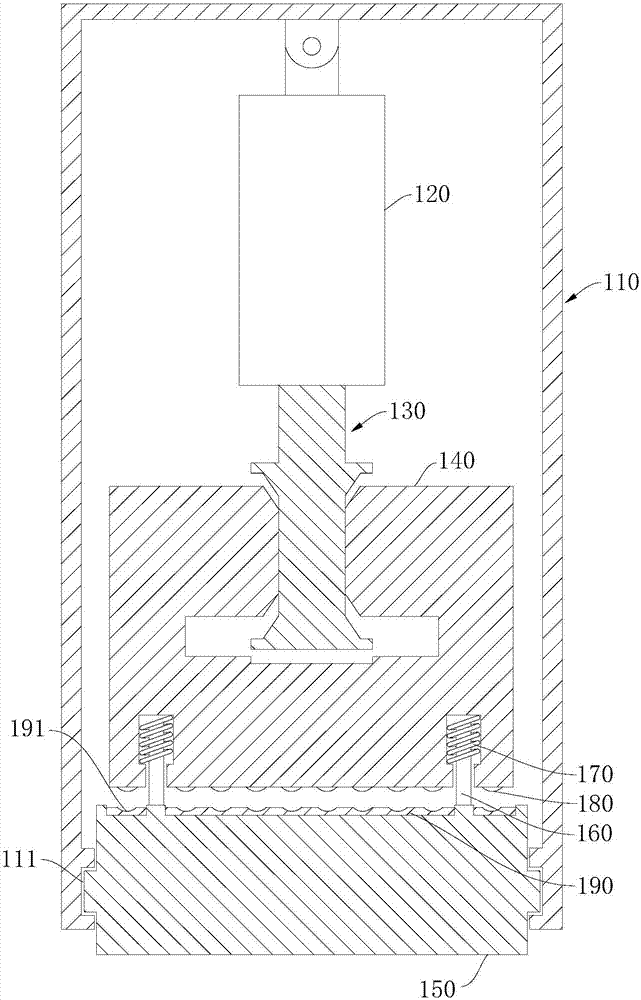

[0034] refer to figure 1 As shown, the embodiment of the present invention provides a hydraulic tamping device, which includes a casing 110 , a hydraulic cylinder 120 , a rammer 140 and a ramming plate 150 .

[0035] In this embodiment, the casing 110 is mainly in the shape of a quadrangular column, and its interior is hollow.

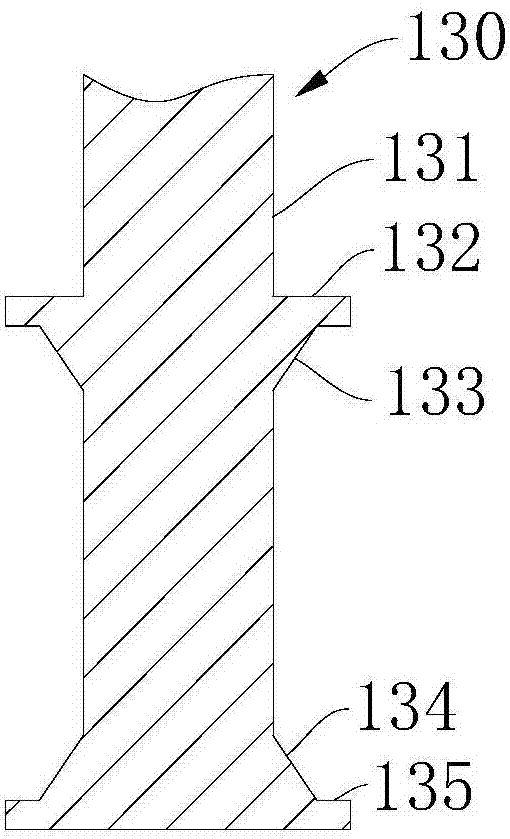

[0036] refer to figure 1 As shown, the hydraulic cylinder 120 is located in the casing 110, and the hydraulic cylinder 120 has a piston rod 130. The end of the hydraulic cylinder 120 away from the piston rod 130 is hinged to the casing 110, and the hinge here can be a hinge.

[0037] Thus, one end of the casing 110 is hinged to the hydraulic cylinder 120 , and the other end of the casing 110 is connected to the tamper plate 150 .

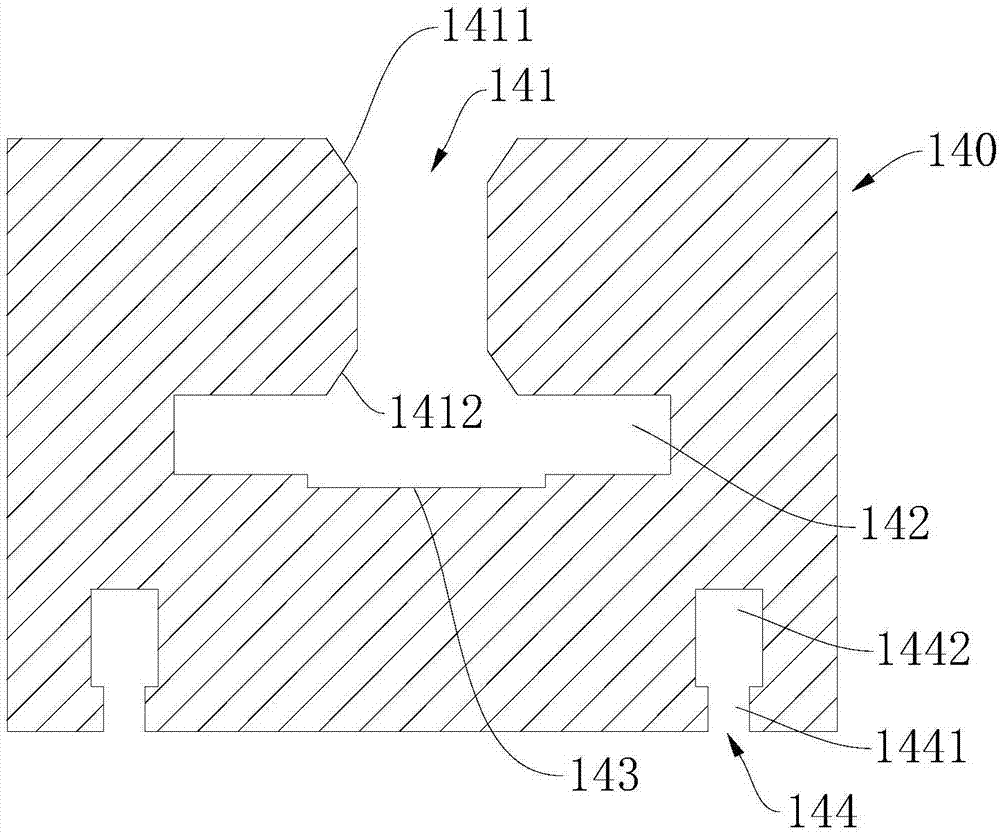

[0038] The rammer 140 is located between the hydraulic cylinder 120 and the rammer 150 , and the rammer 140 is connected to the hydraulic cylinder 120 and the rammer 150 respectively.

[0039] Thus, driven by the hydrauli...

Embodiment 2

[0061] The embodiment of the present invention also provides a hydraulic compaction machine, including a loader, a frame and the above-mentioned hydraulic compaction device, and the loader is connected to the casing 110 of the hydraulic compaction device through the frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com