Construction method of full-sleeve rotary bored pile with fixed reinforcement cage position

A technology of bored cast-in-place piles and construction methods, applied in sheet pile walls, infrastructure engineering, construction and other directions, can solve the problems of high engineering cost, hanging foot piles, low bearing capacity of piles, etc., and achieves control of pile quality, The effect of speeding up construction progress and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

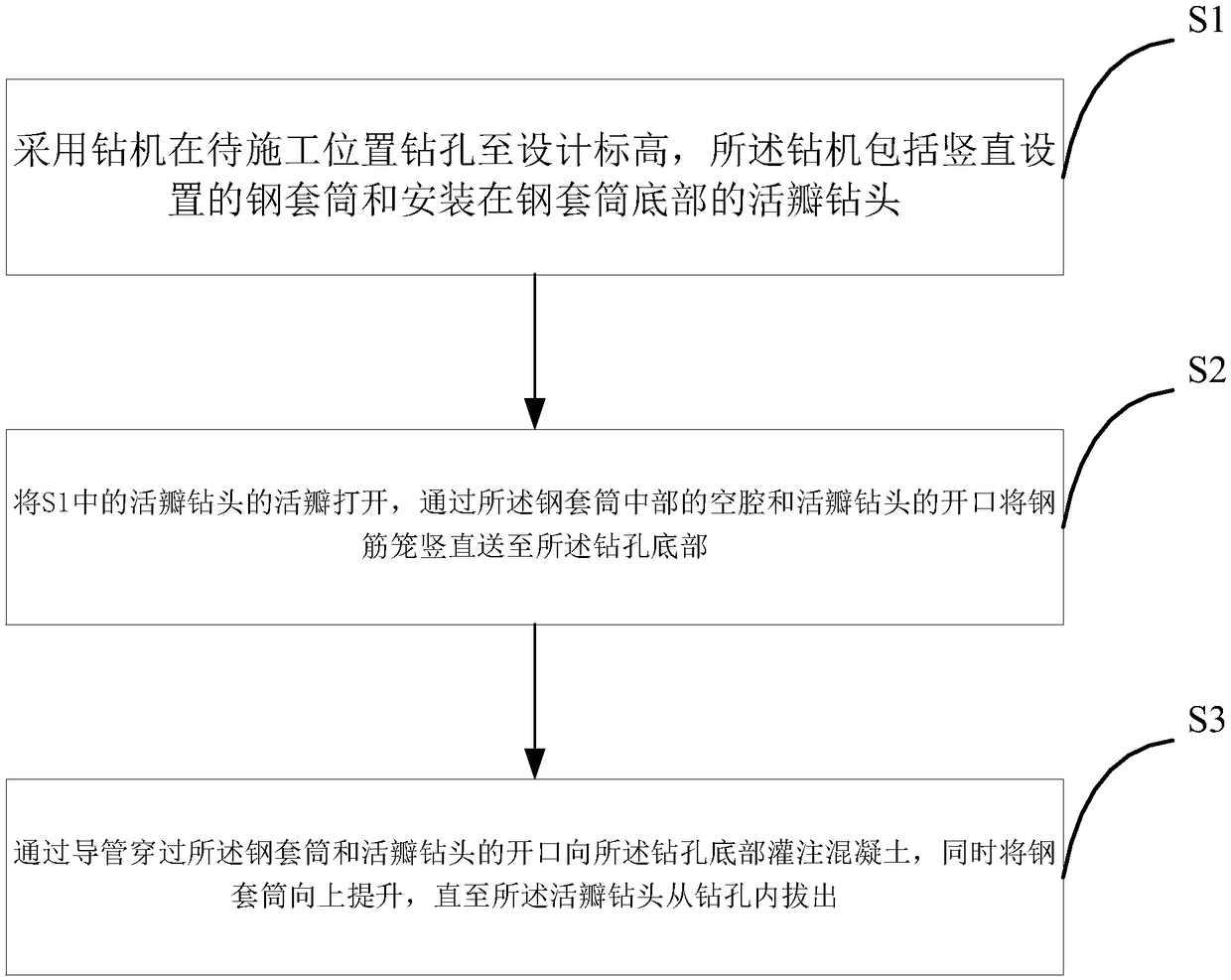

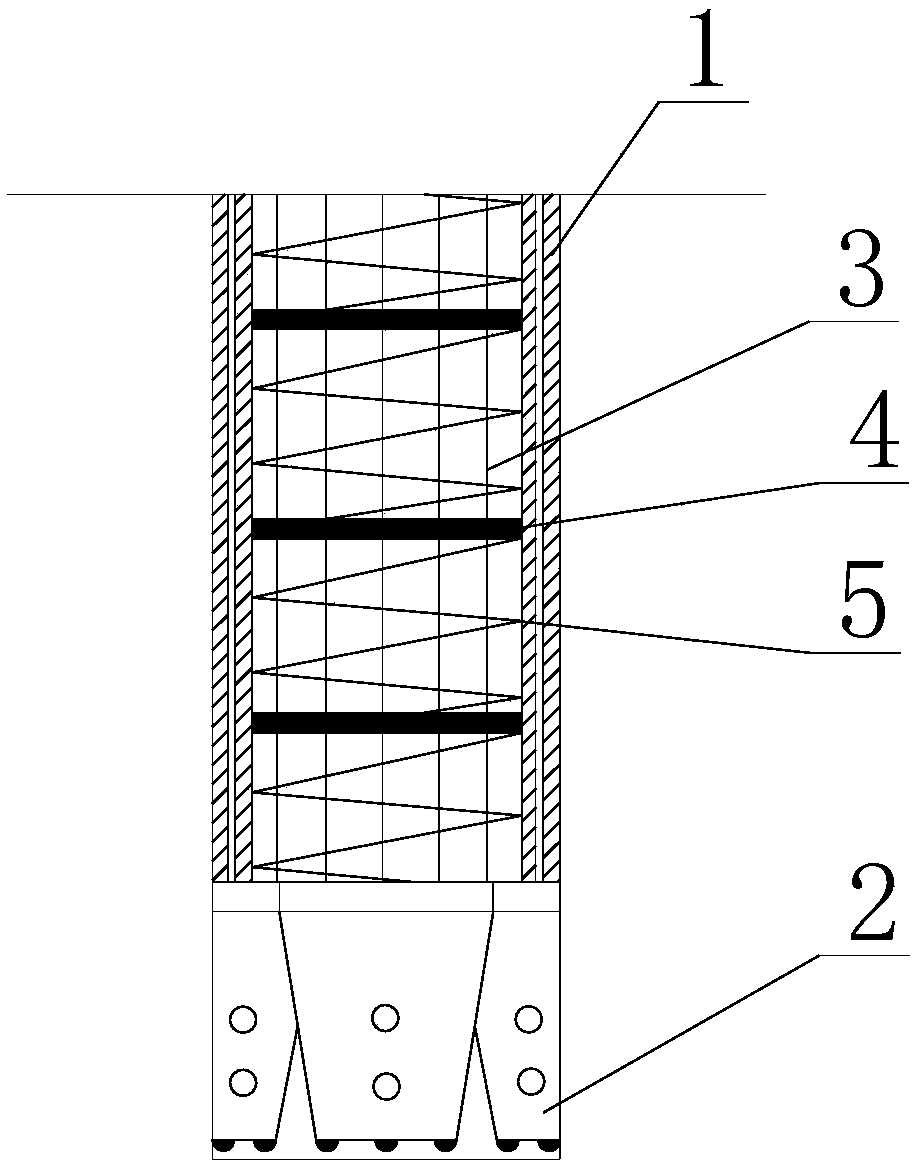

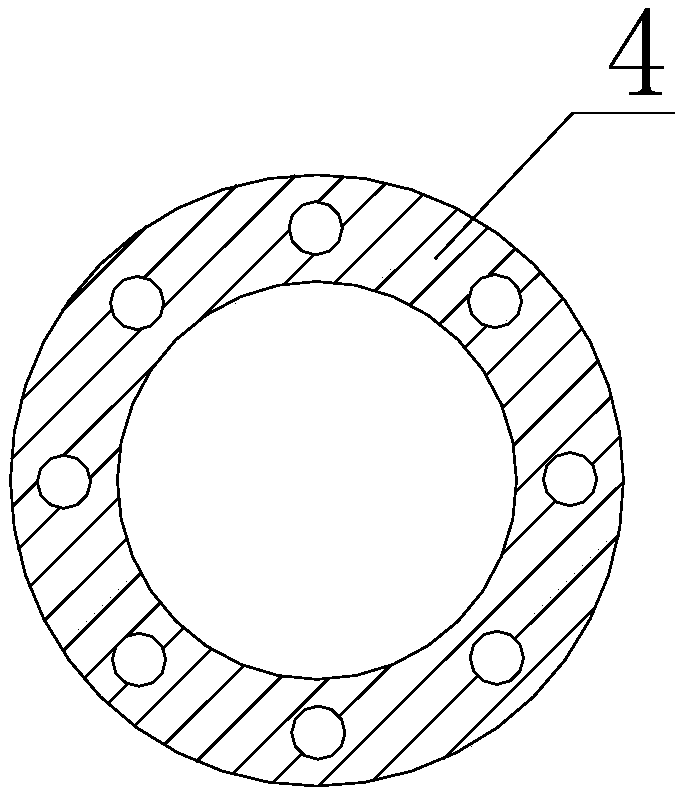

[0023] Such as Figures 1 to 3 as shown, figure 1 It is a flowchart of a construction method for a full-sleeve rotary bored pile with a fixed steel cage position proposed by the present invention, figure 2 It is a structural schematic diagram of the drill bit drilling into the borehole in the construction method of a full-sleeve rotary bored pile construction method with a fixed steel cage position proposed by the present invention, image 3 It is a structural schematic diagram of the steel partition of the reinforcement cage in the construction method of the full-sleeve rotary bored pile with fixed reinforcement cage position proposed by the present invention.

[0024] refer to Figures 1 to 3 A construction method for a full-sleeved rotary bored pile with a fixed steel cage position proposed by the present invention comprises the following steps:

[0025] S1. Use a drilling rig to drill holes to the design elevation at the location to be constructed. The drilling rig inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com