PAR lamp

A lamp head and lampshade technology, applied in the field of PAR lamps, can solve the problems of complicated positioning, low assembly efficiency, easy imaging, etc., and achieve the effect of good light output, good heat dissipation, and elimination of macular

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

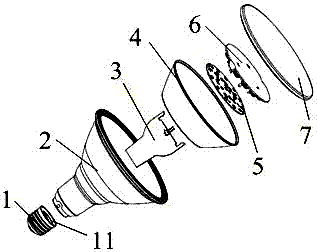

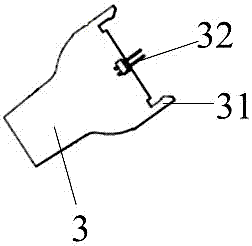

[0058] like Figures 1 to 8 As shown, Embodiment 1 of the present invention provides a PAR (Parabolic Aluminum Reflector dish-shaped aluminum reflection, the same below) lamp, which includes a lamp cap 1, a housing 2 connected to the lamp cap, and a driving power source located inside the housing 2 3. The metal cup 4 located inside the housing 2, the LED lamp board 5 located at the bottom of the metal cup 4, the lens 6 and the lampshade 7 located on the LED lamp board 5;

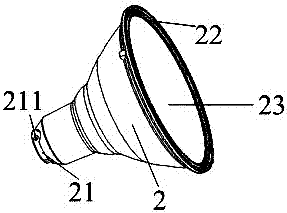

[0059] The housing 2 includes a lamp cap connector 21, and at least one through hole 211 is arranged on the lamp cap connector 21, and the lamp cap connector 211 is connected with the lamp cap 1 through solid glue, and the solid glue penetrates through the through hole 211;

[0060] The housing 2 is made of glass, and includes a lampshade connector 22 on the top of the housing 2. The lampshade 7 is made of glass, and the lampshade 7 matches the size and shape of the lampshade connector 22. , the lampshade ...

Embodiment 2

[0086] like Figures 9 to 14 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the driving power of this embodiment uses a PCB board (Printed circuit board printed circuit board) protruding from the driving power instead of the elastic buckle and conductive pin , corresponding adjustments are made to the structure of the metal cup and the LED light board, specifically:

[0087] A PAR lamp, comprising a lamp base 1, a housing 2 connected to the lamp base, a driving power supply 3 located inside the housing 2, a metal cup 4 located inside the housing 2, and an LED located at the bottom of the metal cup 4 A lamp panel 5, a lens 6 and a lampshade 7 located on the LED lamp panel 5;

[0088] The lamp cap 1 is used to realize the mechanical and electrical connection between the PAR lamp and the external power supply, which can be a threaded lamp cap or a bayonet lamp cap, and different types of lamp caps can be selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com