Flat-plate furnace

A flat-plate furnace, furnace door sealing technology, applied in incinerators, combustion methods, combustion types and other directions, can solve the problems of high labor intensity, low combustion efficiency, long cremation time, etc. The effect of short cremation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

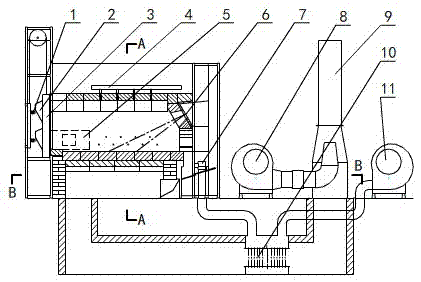

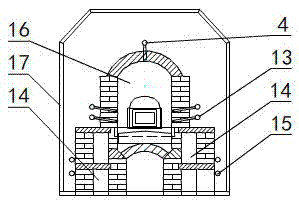

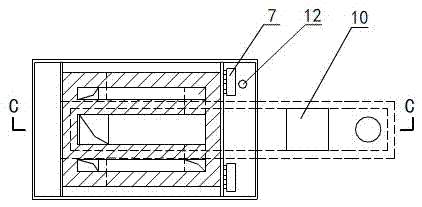

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] The spring of the present invention 1 High-quality springs with high temperature resistance are selected, 1 The role is to pass through the inclined iron block 2 Give the furnace door a certain pre-pressure, that is, to ensure that there is a requirement for sealing. When the pressure in the furnace is too high, the furnace door will 3 A certain gap is created to ensure that the pressure in the furnace is not too high. Top duct 4 , side air duct 13 and upwind pipe 15 They are all made of stainless steel tubes, and their function is to supply high-pressure air to the furnace to accelerate incineration and shorten the cremation time. fuel injection port 6 The function is to spray fuel oil into the furnace during the incineration process to improve the incineration effect, and the bellows 7 The function is to supply air to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com