Intensified burner

A burner and combustion chamber technology, applied in the directions of burners, gas fuel burners, combustion methods, etc., can solve the problems of insufficient utilization of combustible substances, insufficient combustion of the burner, serious pollution, etc., and achieves simple structure, Low cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

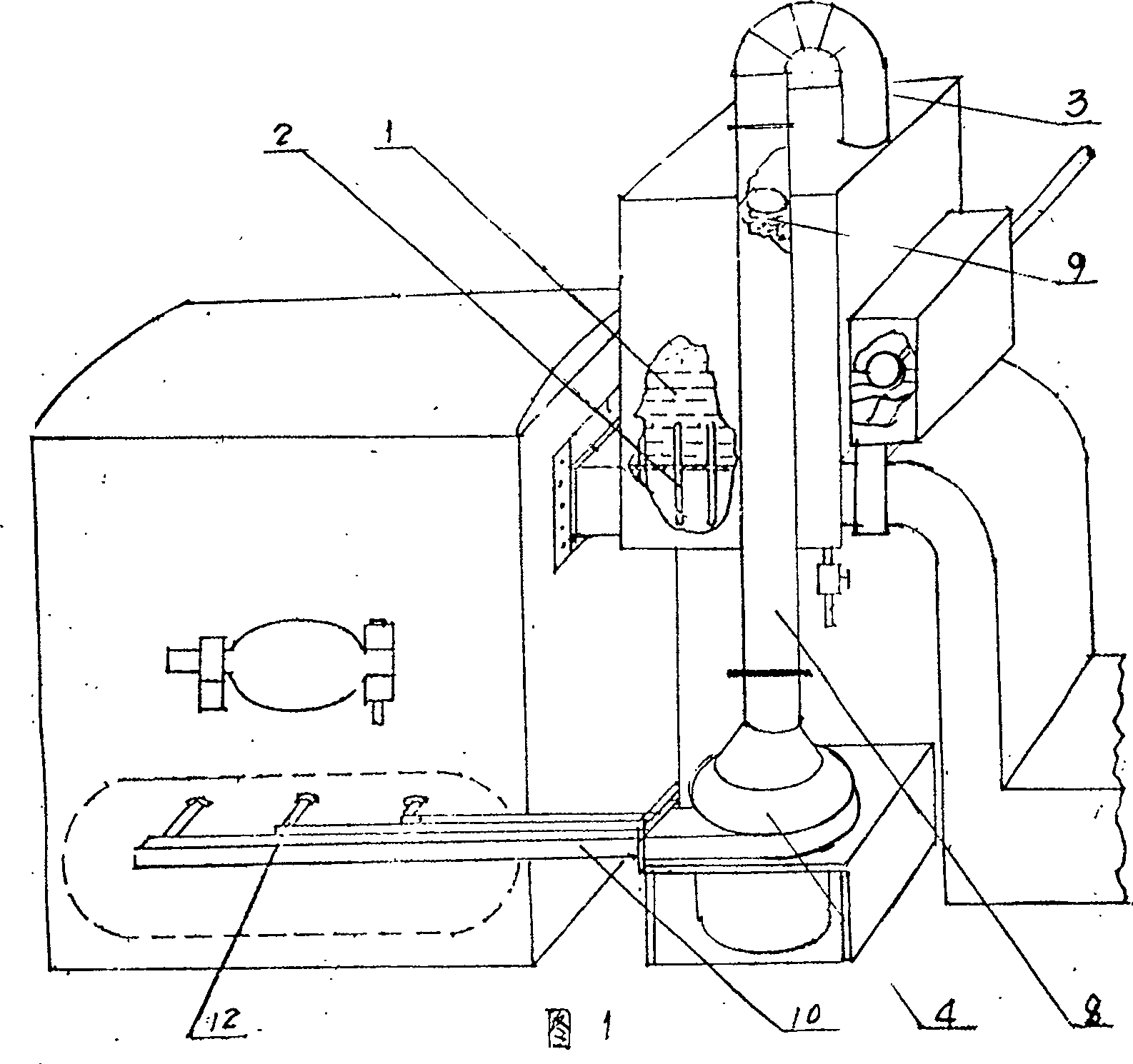

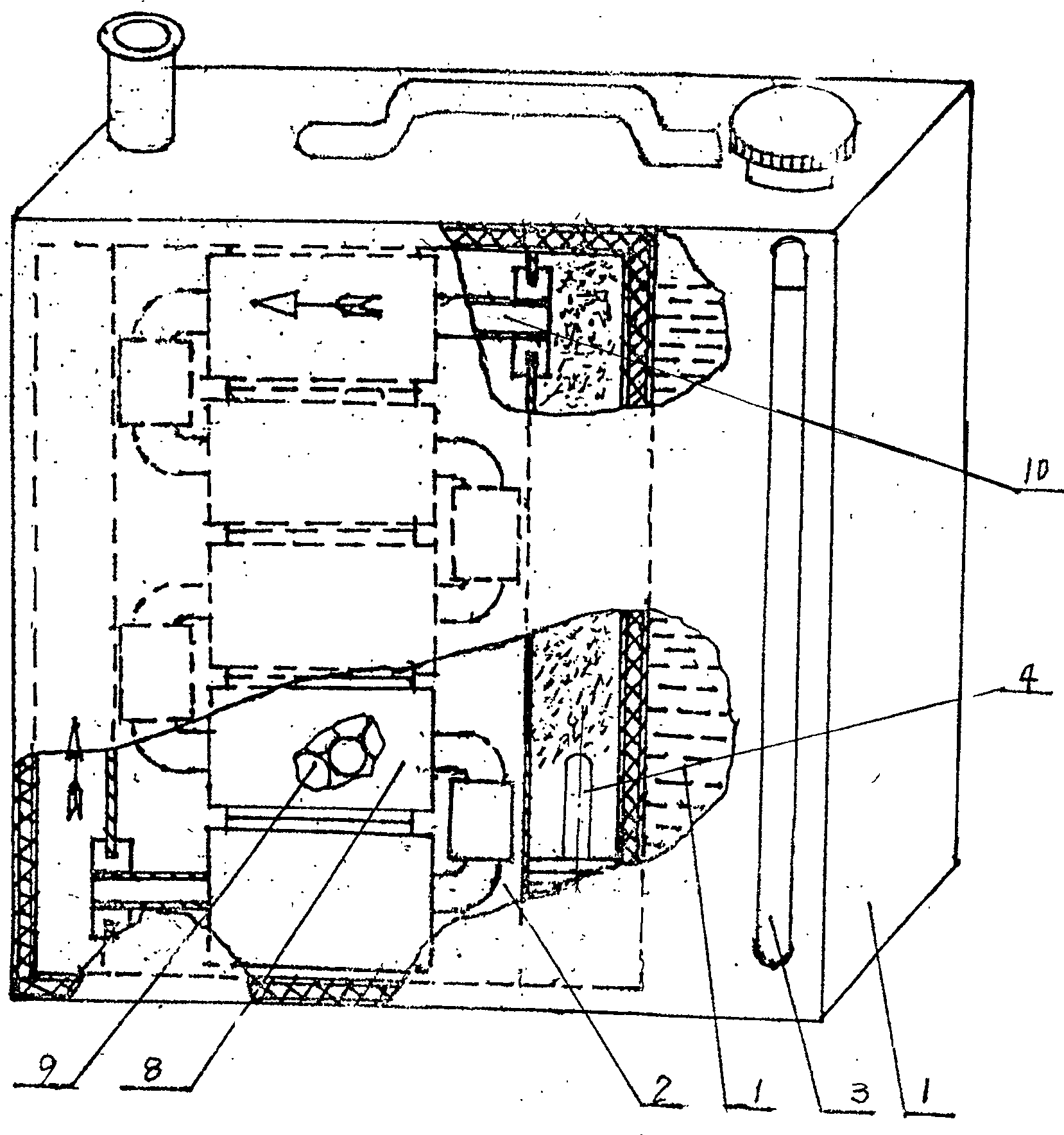

[0018] The strengthened burner comprises: a water storage tank 1, a heating device 2 is installed in the water storage tank 1, and the water storage tank 1 is connected with a columnar catalytic chamber 8 through its gas supply pipe 3, and the catalytic chamber 8 is Catalyst 9 is installed, and the catalyst is a mixture of oxidation or rare earth chloride, iron oxide such as ferric oxide or ferric oxide or a mixture thereof, calcium carbonate, and magnesium oxide, and the ratio of parts by weight is 4: 3:1:2, the outlet pipe 10 of the catalytic chamber 8 leads to the combustion grate 12 or the combustion chamber of the automobile engine. After the water vapor is activated by the rare earth material, the combustion is enhanced by this device.

Embodiment 2

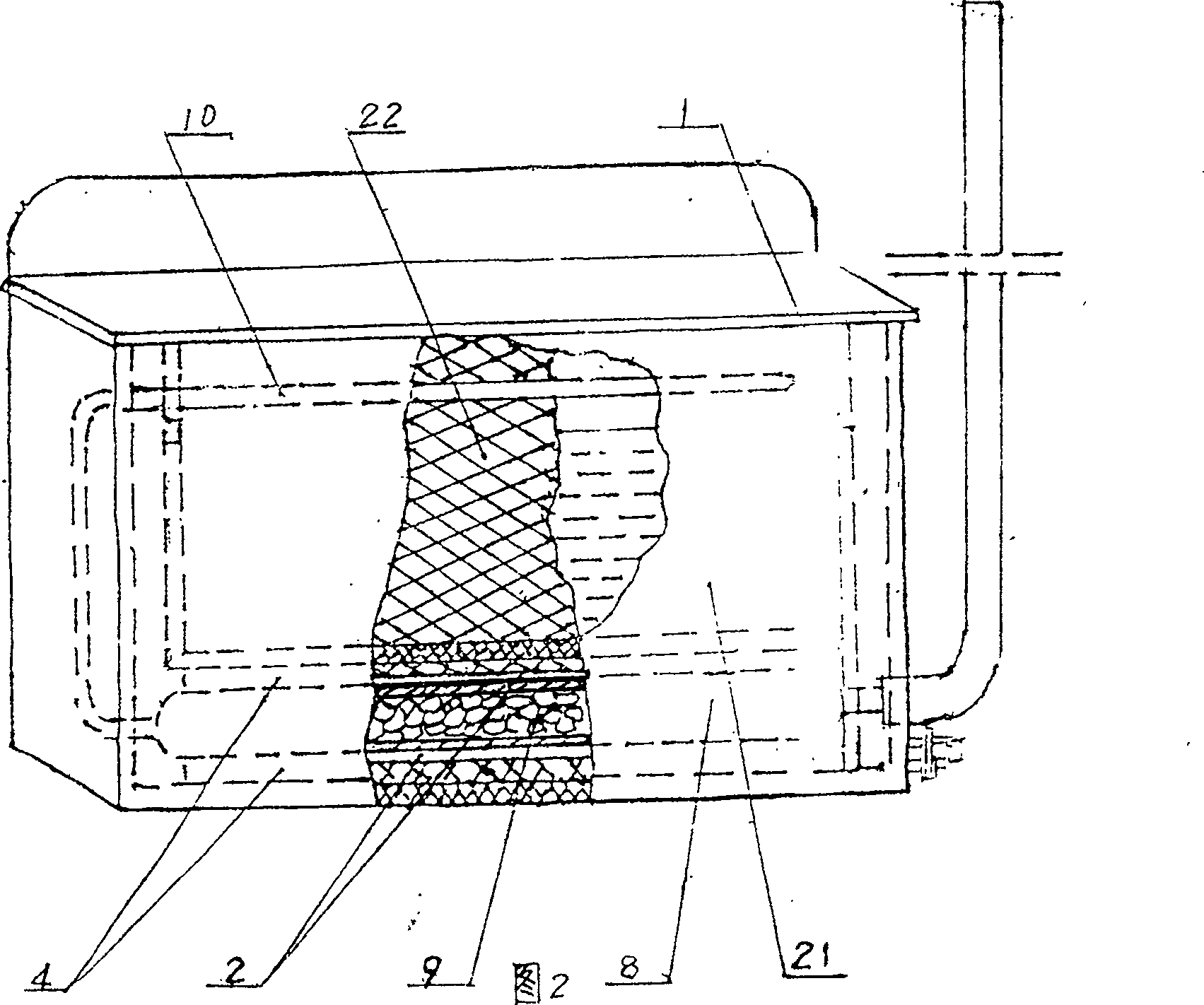

[0020] For the above-mentioned enhanced burner, when the catalytic chamber 8 is installed on the boiler, the heating device 2 is a boiler flue, and the water vapor heated by the flue in the air supply pipe 3 enters the catalytic chamber through the air supply pipe 3 8. The outlet of the gas outlet pipe 10 of the catalytic chamber is located at the combustion grate 12 of the boiler combustion chamber, such as arranged on both sides of it or above it along the length of the grate.

Embodiment 3

[0022] For the enhanced burner described in Example 1, when the catalytic chamber 8 is installed on the automobile, the heating device 2 is a set of electric heating tubes, and the catalytic chamber 8 and the heating device 2 are all installed in the water storage tank 1, water-absorbing sponge 22 is housed in the water storage tank 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com