Test fixture for simply supported beam fatigue loading and use method of test fixture

A fatigue loading and test fixture technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost and long fatigue test time, achieve easy loading and unloading, reduce time and cost consumption, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

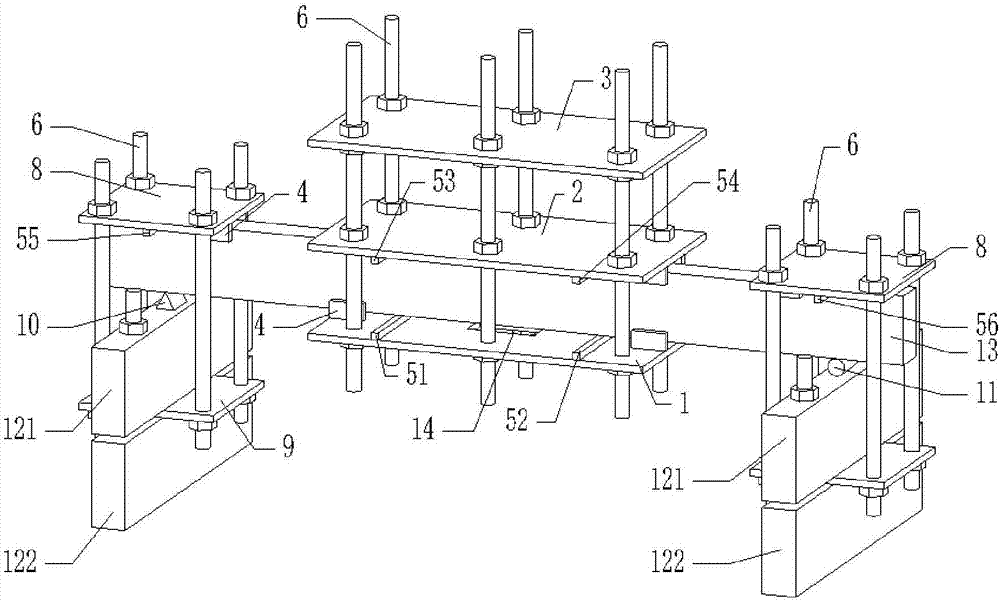

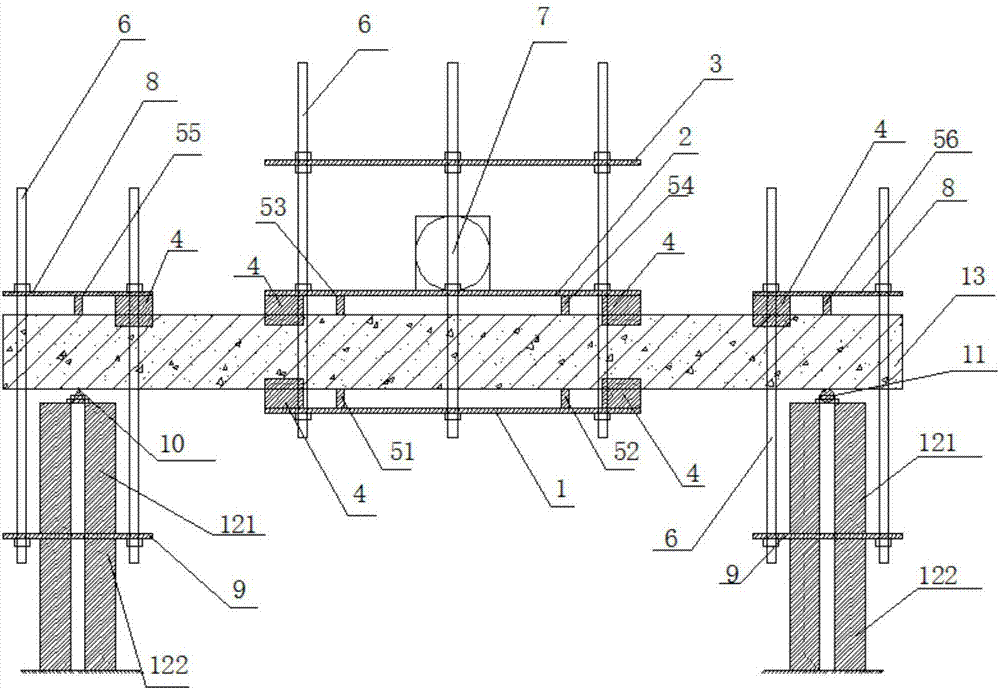

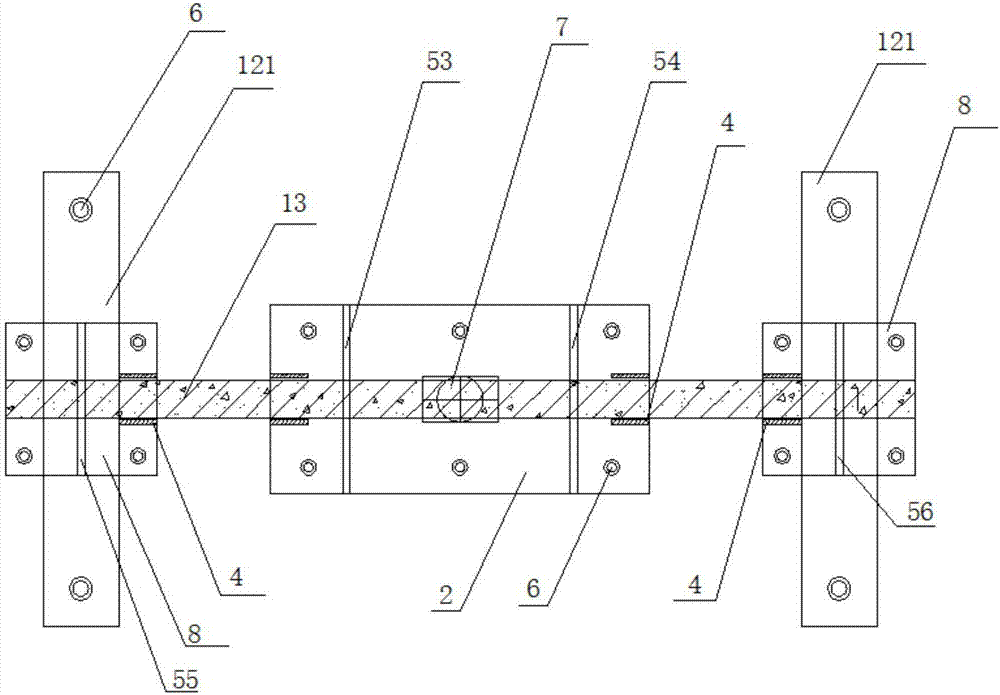

[0043] Example: such as Figure 1-Figure 9 As shown, a test fixture for fatigue loading of simply supported beams in the present invention includes fixture I arranged at the mid-span of simply supported beam 13, fixture II and vibration motor 7 arranged at both ends of simply supported beam 13, as Figure 4As shown, the clamp I includes fastening plates I1, fastening plates II2, screw nuts, splints 4 and load ribs 51, 52, 53 and 54 placed on the upper and lower sides of the simply supported beam 13. The fastening plates I1 It is connected with the fastening plate II2 through a screw 6 and a nut, and the two sides of the simply supported beam 13 on the opposite surface of the fastening plate I1 and the fastening plate II2 are respectively provided with splints 4 (contacting, not extruded) to ensure simple support The beam 13 does not move or fall during the fatigue loading process, and two load ribs 51 and 52 are set between the fastening plate I1 and the simply supported beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com