Wiring and shaping device of optical projection

A technology of optical projection and projection screen, which is applied in the field of optical projection wiring forming devices and production and production devices, can solve the problem of being unable to adapt to the development needs of paperless and information-based production, easily scratching the insulation sheath of wires, and leaving behind equipment and products. Quality and other issues, to achieve the effect of improving production efficiency and quality, easy to operate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

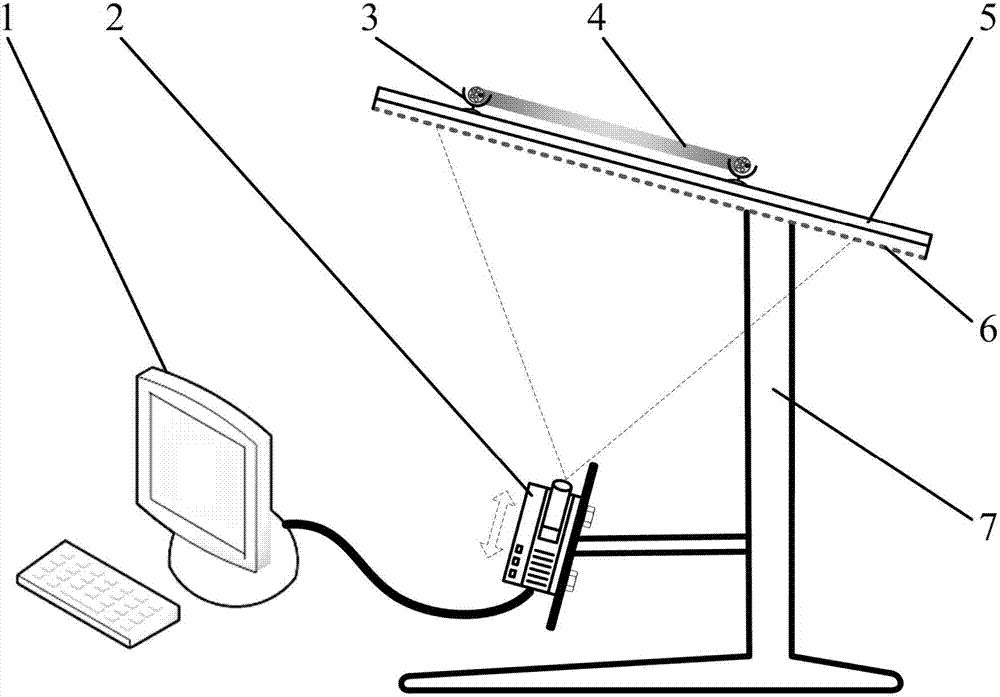

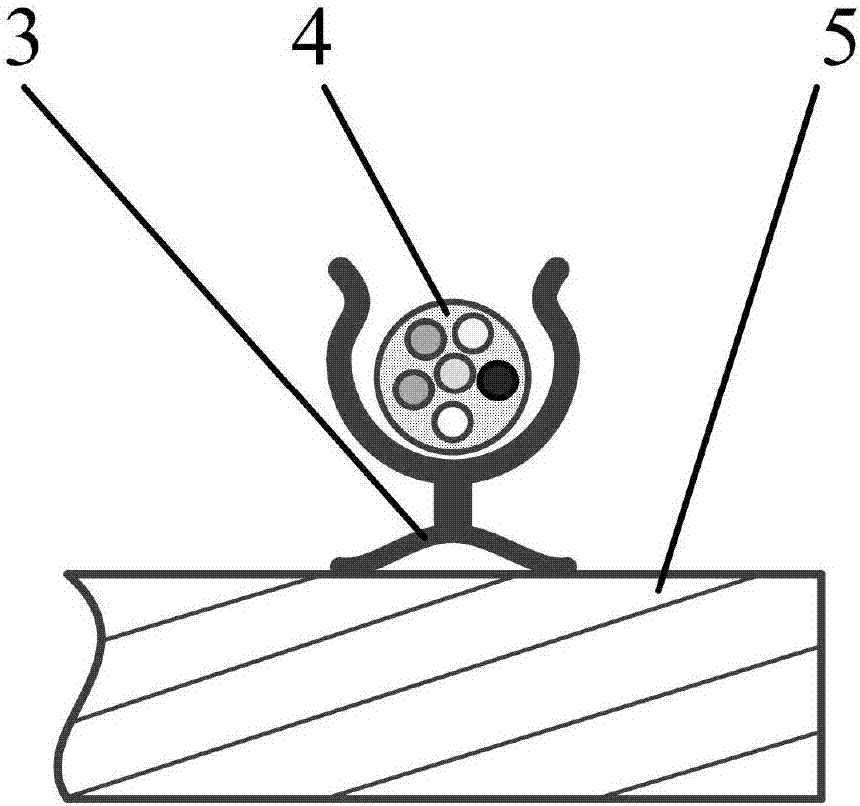

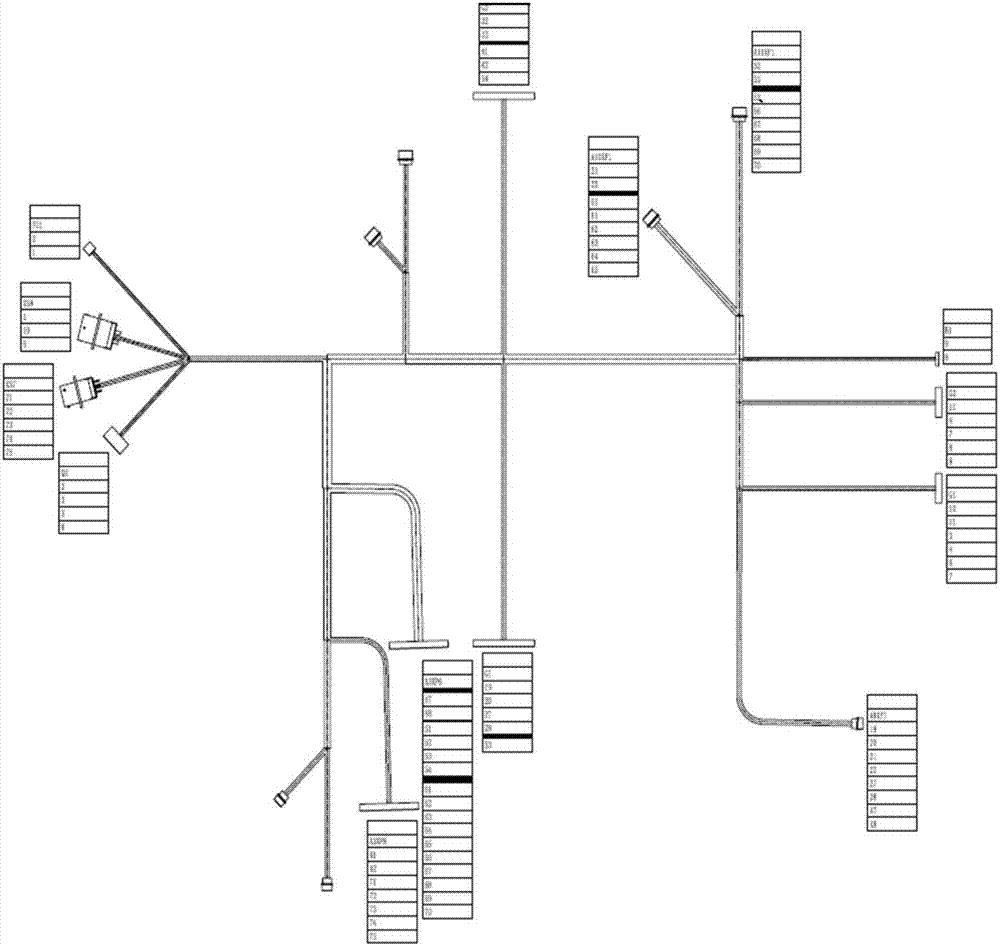

[0015] Refer to figure 1 . In the embodiment described below, the optical projection wiring forming device includes: an optical projector 2, a cable fixing member 3, a transparent wiring forming plate 5, a translucent projection screen 6, and a workbench support 7, characterized by: workbench support 7 is provided with an optical projector 2 under the transparent wiring forming board 5. The optical projector 2 uses the computer 1 to form a nail board diagram with the wiring relationship of the cable bundle 4 and its shape and geometric size information, in a ratio of 1:1 Projected on the translucent projection screen 6, the operator observes the drawings on the translucent projection screen 6 through the transparent wiring forming board 5, and forming the cable bundle 4 on the transparent wiring forming board 5, and the branch of the cable bundle 4 , Turning, etc. are positioned and fixed on the transparent wiring forming board 5 by the cable fixing member 3.

[0016] Preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com