Electronic components typesetting machine

A technology for electronic components and typesetting machines, applied in the direction of electrical components, electrical components, etc., can solve the problems of unable to meet the requirements of automatic typesetting of products, unable to meet the needs of mass production, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

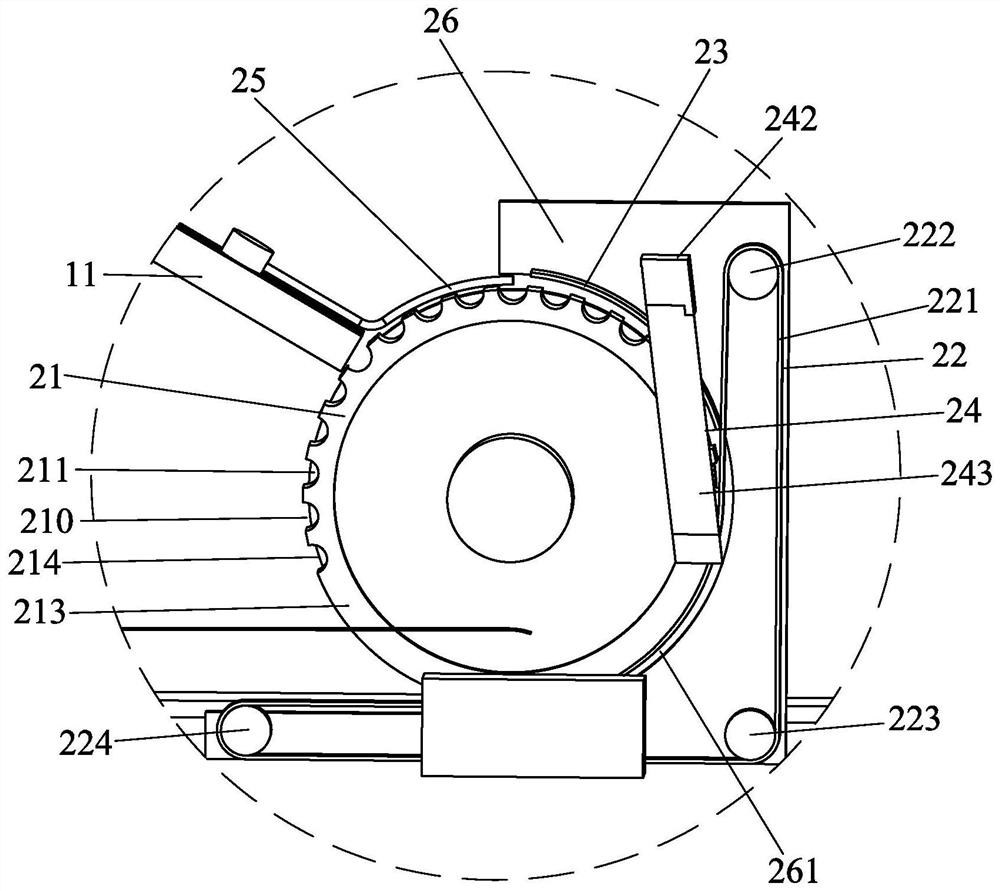

[0025] In order to describe in detail the technical content, structural features, and achieved effects of the present invention, detailed descriptions are given below with reference to the embodiments and the accompanying drawings.

[0026] see Figure 5 , in a specific embodiment of the present invention, an electronic component typesetting machine is used to typeset the capacitor core 900, the capacitor core 900 has a main body 901 and two pins 902 extending from one end of the main body 901, and the electronic component typeset The machine places the pins 902 of several capacitor cores 900 on the strip B in turn and covers them with paper tape P at the same time to glue the pins 902 on the strip B; The other end is uneven.

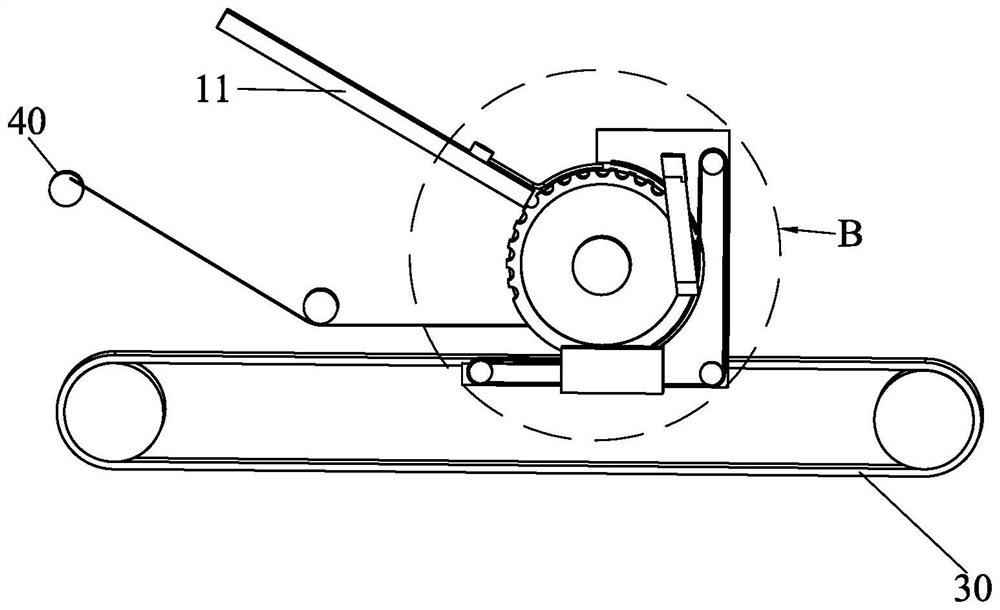

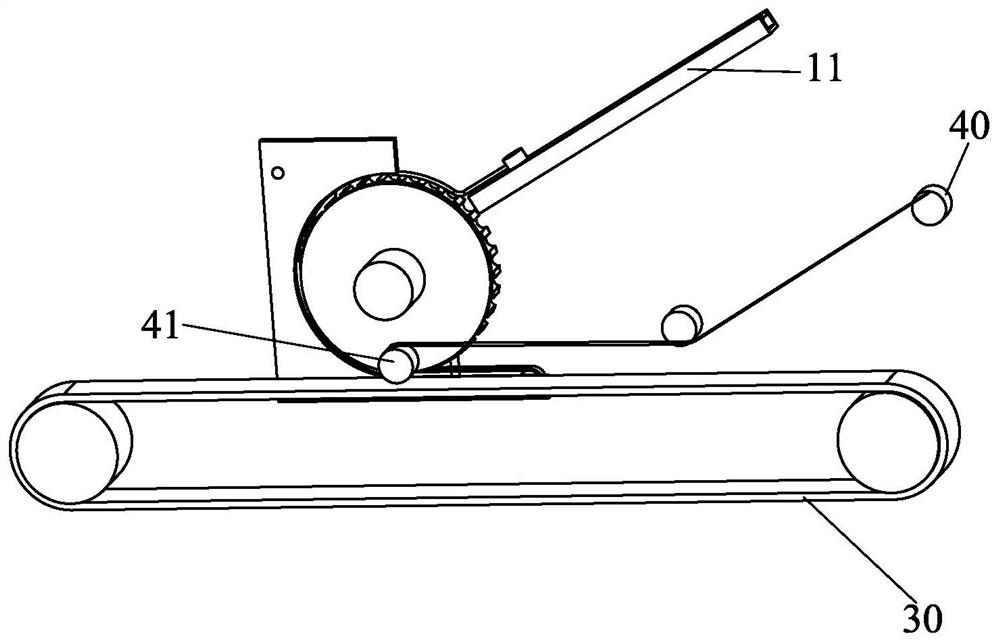

[0027] see Figure 1 to Figure 4 , the electronic component typesetting machine includes a component feeding device, a component conveying device, a strip conveying device 30, a paper tape conveying device 40 and a control drive module (not shown), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com