Photovoltaic typesetting machine

A typesetting machine and photovoltaic technology, applied in the direction of photovoltaic power generation, auxiliary devices, electrical components, etc., can solve the problems of low typesetting efficiency and high labor intensity, and achieve the effect of improving typesetting efficiency, reducing labor intensity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

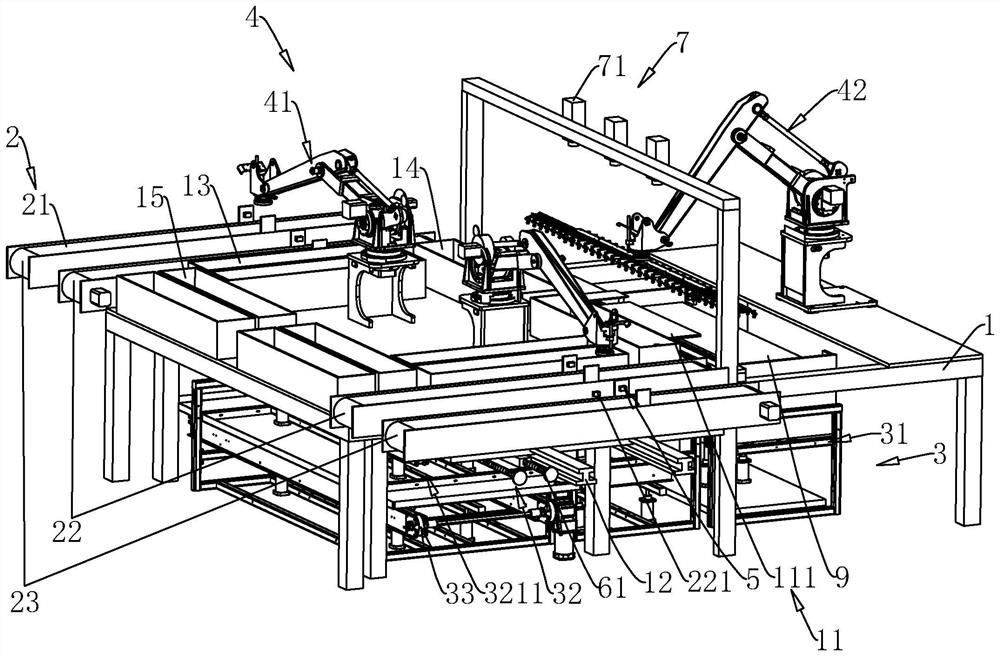

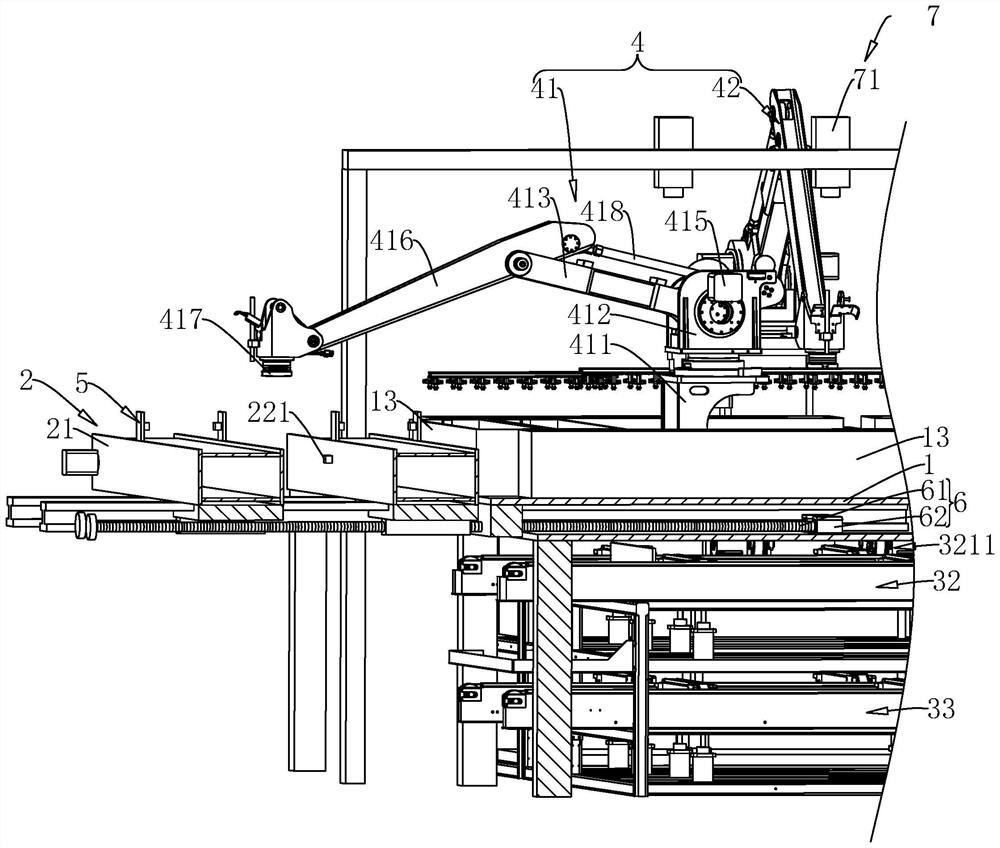

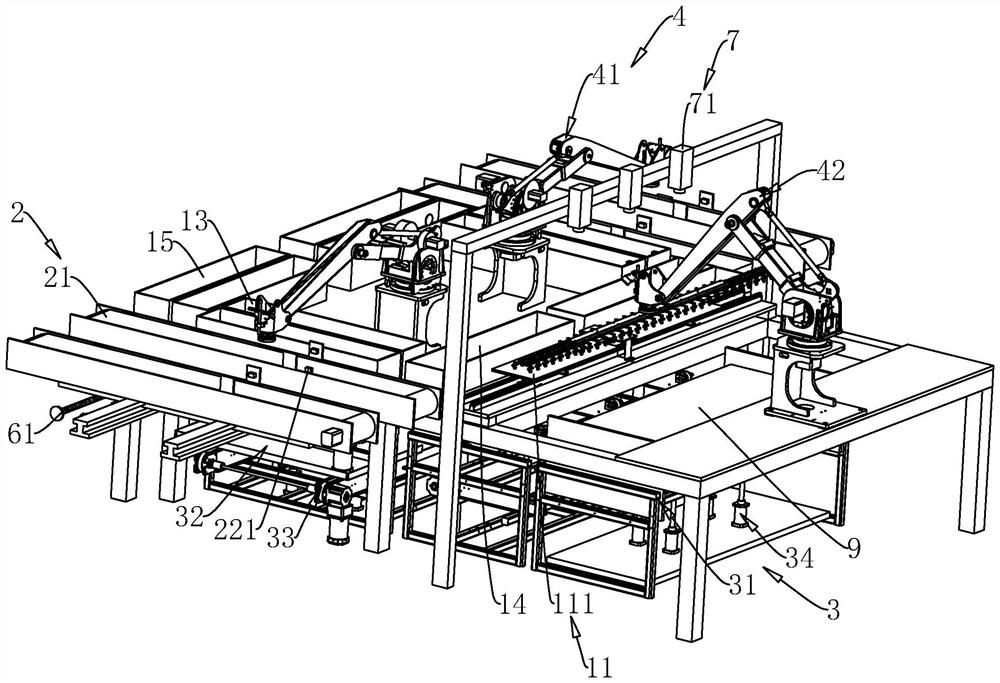

[0040] The following is attached Figure 1-8 The application is described in further detail.

[0041] The embodiment of the present application discloses a photovoltaic typesetting machine. refer to figure 1 , The photovoltaic typesetting machine includes a placement frame 1, a wiring device 2 for receiving battery strings output from the welding outlet is provided on the side of the placement frame 1, and a wiring device 2 for receiving the battery string output from the welding outlet is provided on the lower side of the placement frame 1. The glass 9 of the film moves to the transmission mechanism 3 on the side of the wiring device 2, and the holding mechanism 4 for moving the battery strings on the wiring device 2 to the glass 9 is arranged on the placement frame 1 to realize layout. When in use, directly place one end of the wiring device 2 at the outlet of the welding machine, and the welded battery string output from the outlet of the welding machine will reach the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com