An automatic unwinding machine for mulch film

An automatic unloading and filming technology, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., to achieve the effects of increasing competitiveness, improving product quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

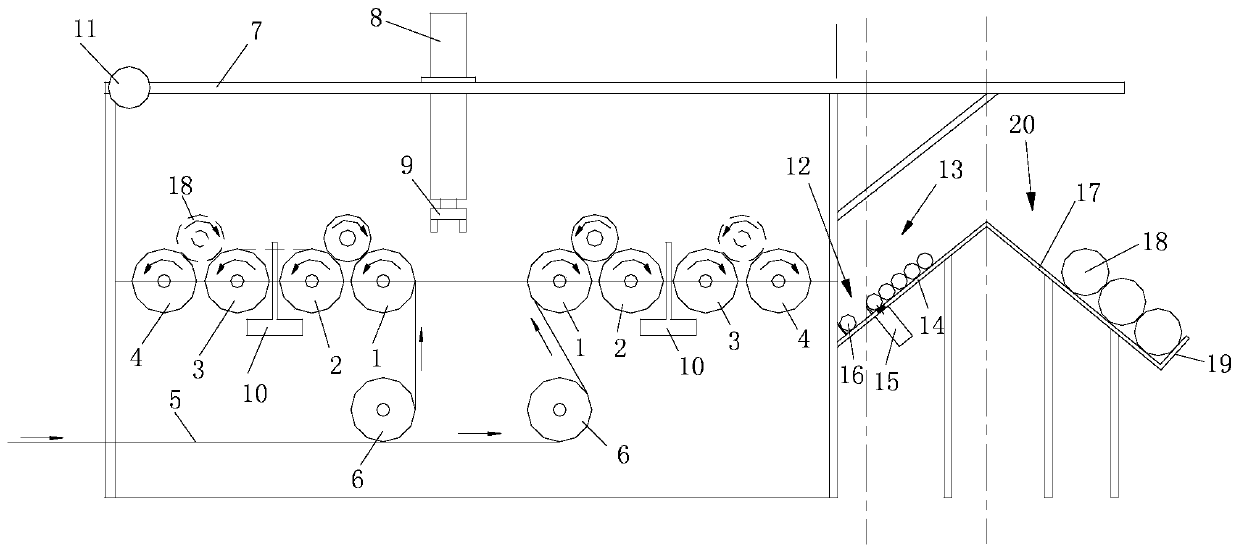

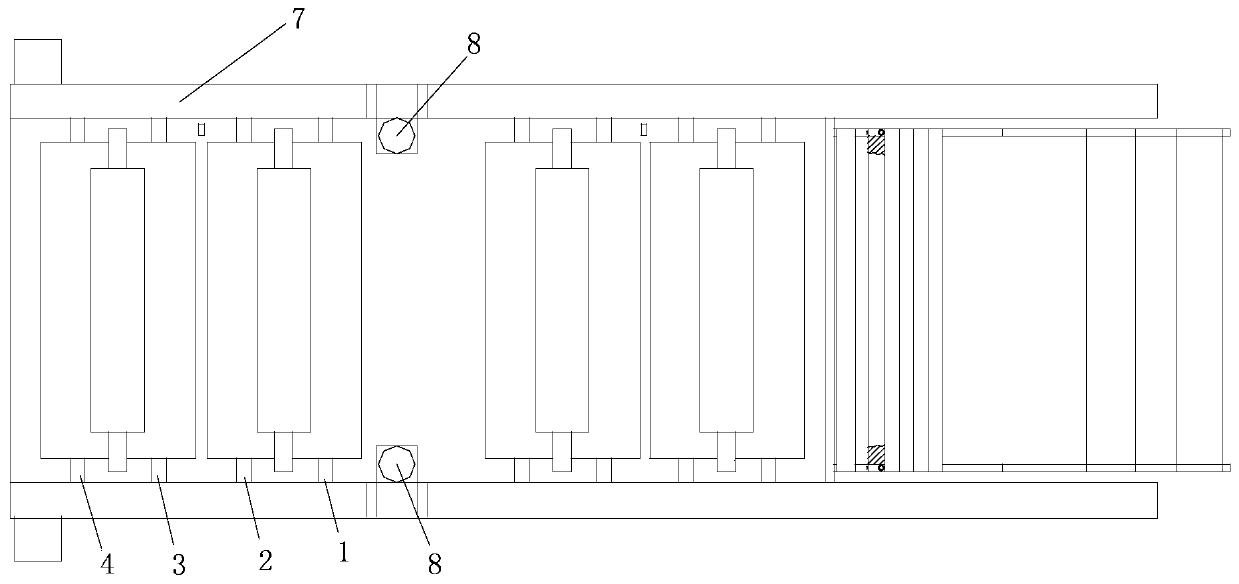

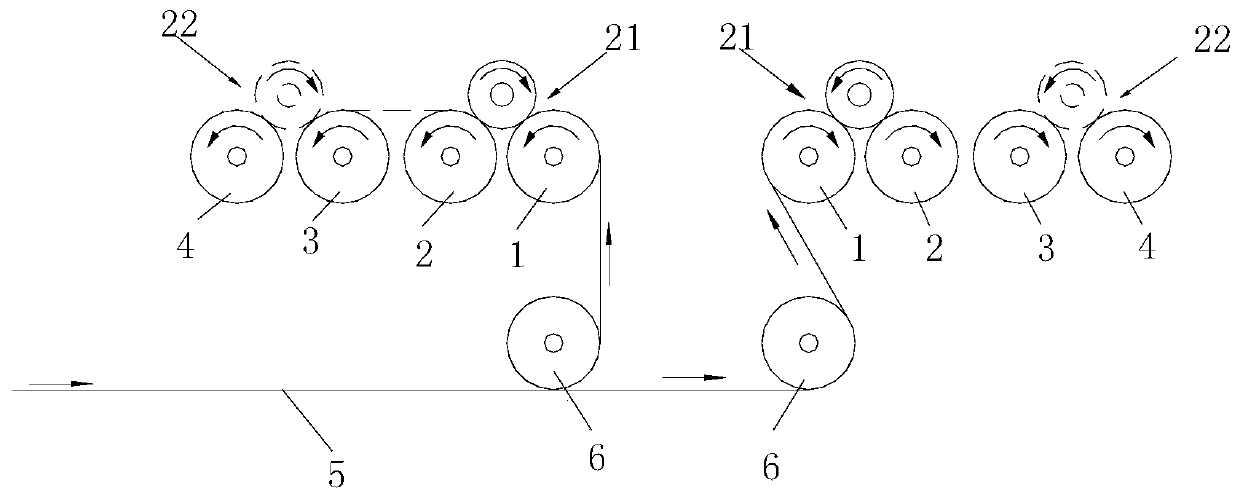

[0031] Such as Figure 1 to Figure 3 As shown, an automatic film unloading machine includes a frame on which an empty roll storage area, a full roll storage area 20 and a winding area are arranged, and a plurality of empty rolls of unwrapped plastic film 5 are placed in the empty roll storage area The roll 16, the full roll storage area is used to store the full roll 18 wrapped with the mulch film 5 of a specified thickness. The specific film thickness on the roll is set according to actual requirements. In order to make the demarcation between the regions clearer and easier to express, figure 1 Dotted lines are set in the drawing.

[0032] Below, the present invention will be further described by taking the winding area provided with two film winding stations as an exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com