A film unwinding automatic cutting device and film automatic unwinding equipment

An automatic cutting device and automatic unloading technology, which is applied in the field of film manufacturing, can solve the problems of reducing cutting efficiency, discounting cutting effects, and increasing manufacturing costs, and achieves the effects of improving operating efficiency, facilitating installation and maintenance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

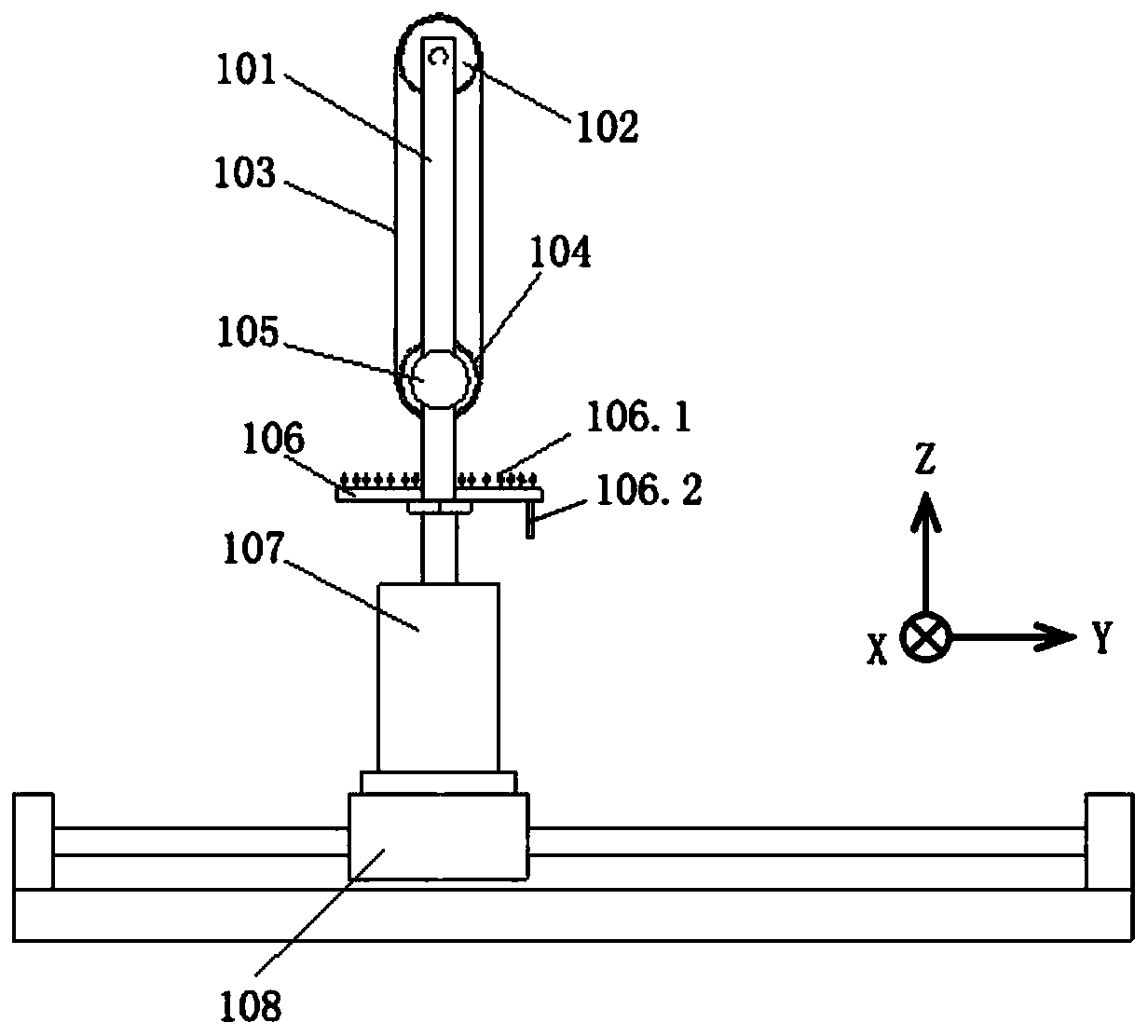

[0034] like figure 1 As shown, an automatic cutting device for film unwinding includes a cutter mechanism and a first power device that drives the cutter mechanism to move up and down along the Z-axis direction and translates along the Y-axis direction. The cutter mechanism includes a support plate 101 and is arranged on The upper sprocket 102 on the top of the support plate 101, the lower sprocket 104 that is arranged on the bottom of the support plate 101, the motor 105 that drives the rotation of the lower sprocket 104 and the chain saw 103 that is arranged on the upper and lower sprockets, the support plate 101 can be Driven by the first power device, it moves up and down along the Z axis, and makes a reciprocating linear motion along the Y axis.

[0035]The first power device includes a first linear drive mechanism, a Y-direction translation mechanism and a Z-direction lifting mechanism 107. The Y-direction translation mechanism includes a Y-direction slide table 108, and...

Embodiment 2

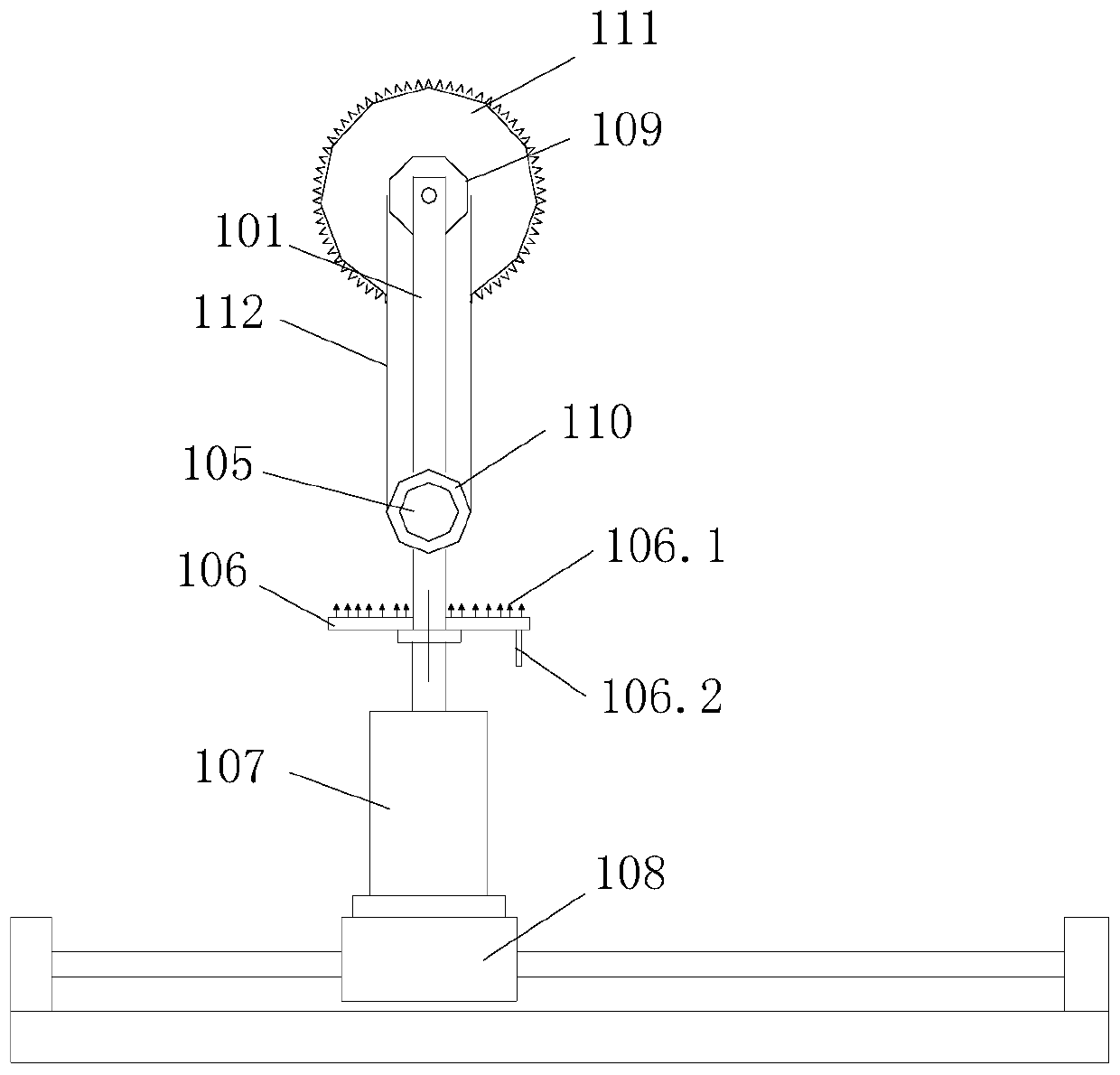

[0040] like figure 2 As shown, the structure and principle of the second embodiment are basically the same as those of the first embodiment, the only difference is that the cutter mechanism of the second embodiment is changed, and the cutter mechanism includes an upper pulley 109 arranged on the upper part of the support plate 101 , the lower pulley 110 arranged on the bottom of the support plate 101 and the timing belt 112 arranged on the upper and lower pulleys, the support plate 101 is also provided with a motor 105 that drives the rotation of the lower pulley 110, and the wheel shaft of the upper pulley 109 is also provided with There is a circular saw 111 .

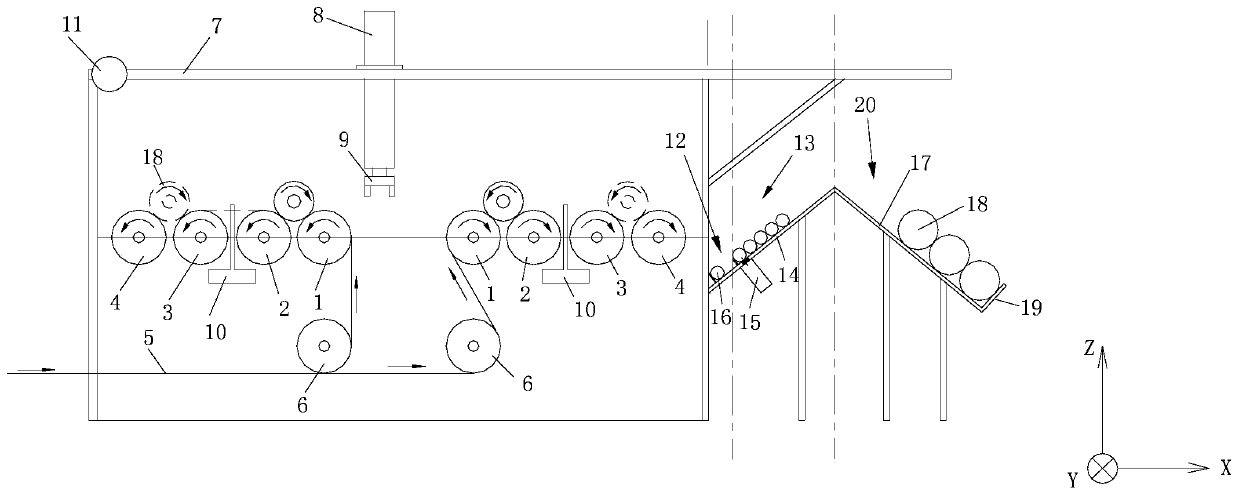

[0041] like Figure 1 to Figure 5 As shown, the present invention also discloses an automatic film unloading device, including an automatic film unloading machine and the above-mentioned automatic cutting device, the automatic film unloading machine includes a frame, and an empty roll storage area is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com