PCB warping detection device, method and system

A PCB board and detection device technology, applied in the field of PCB board warpage detection devices, can solve the problems of increasing processing steps, inaccurate detection, board surface pollution, etc., and achieve flexible and accurate detection, avoid detection missed detection, and high detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In order to solve the relevant technical problems raised in the background art, this embodiment proposes a PCB warpage detection device and method, especially for high-density PCB boards and special-shaped asymmetric PCB boards, to achieve accurate and efficient detection of their warpage.

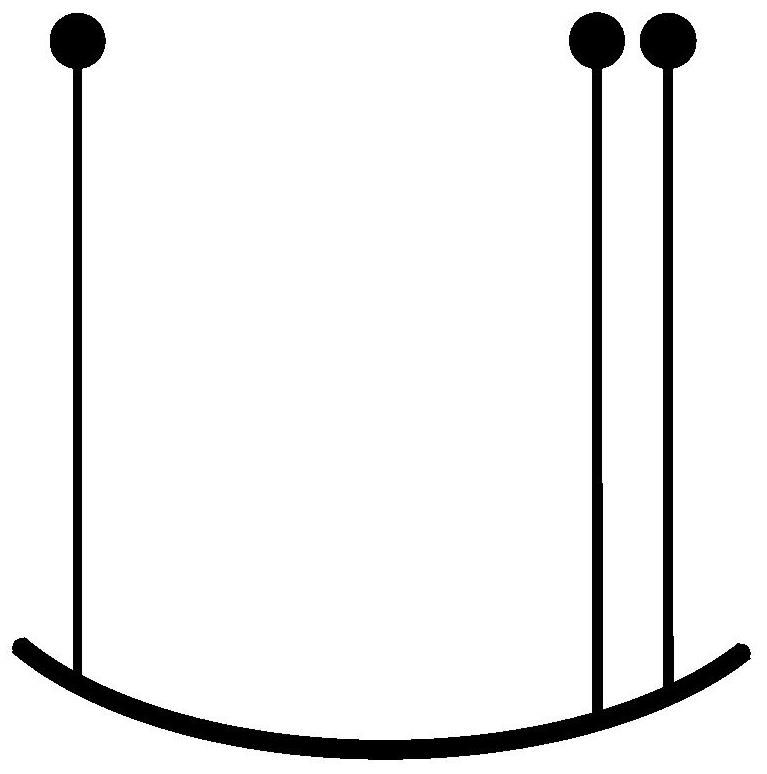

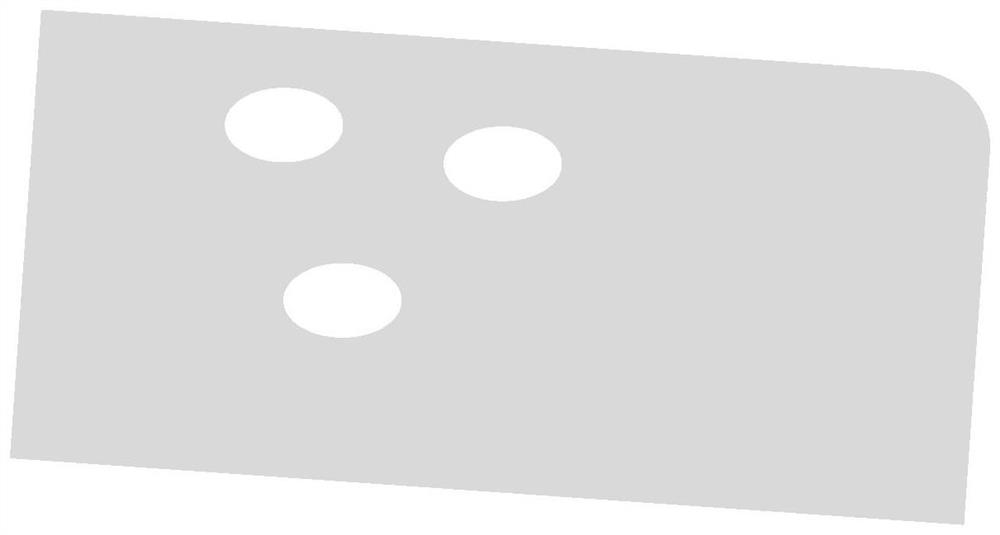

[0038] Such as figure 1 As shown, the PCB warpage detection device includes a detection table arranged under the detection device. The detection table is used to carry and position the PCB board to be tested. When testing, the PCB board to be detected is positioned on the detection table. The mature positioning methods in the prior art, such as positioning clamps and positioning screws, are used to position the PCB to be tested, which will not be repeated here.

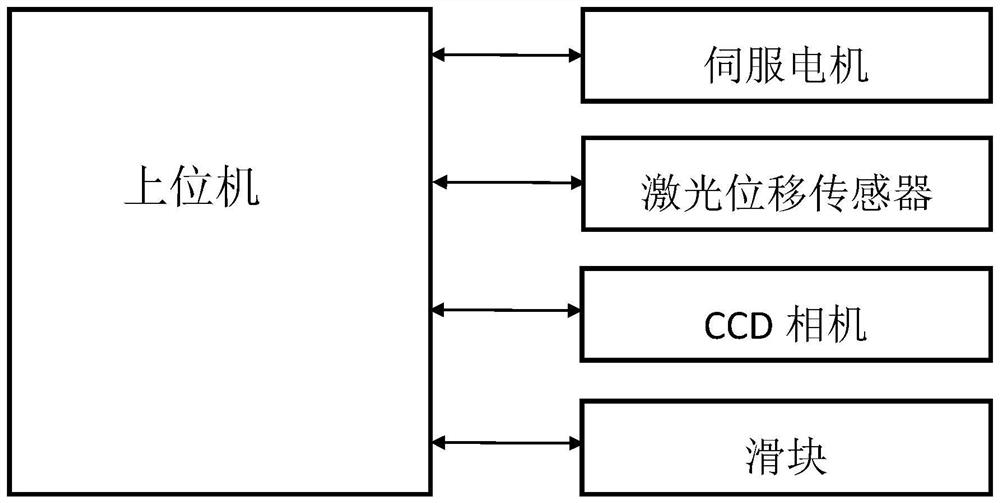

[0039] In this embodiment, a slider and a servo motor that can slide in any direction along the XY plane are arranged directly above the detection device, and the servo motor can drive the slider to slide precisely in the X...

Embodiment 2

[0054] This embodiment is further improved on the basis of Embodiment 1, and the common parts of the technical solutions will not be repeated here.

[0055] This embodiment also provides a PCB warpage detection method, which is supposed to realize the detection of PCB warpage according to the PCB warpage detection in Embodiment 1. Such as Figure 4 As shown, the method specifically includes the following steps:

[0056] Step S1. Generate a detection path for local detection. Input the original design CAD layout of the PCB board to the host computer, and generate the detection path according to the CAD layout;

[0057] In this embodiment, the detection path is determined by the edge of the PCB board and the position of key components. This step can realize the detection of key parts of special-shaped asymmetric PCB or high-speed PCB, and improve the efficiency of detection.

[0058] Step S2, performing local warpage detection. The host computer controls the servo motor to d...

Embodiment 3

[0069] This embodiment is further improved on the basis of embodiment 1 or embodiment 2, and the common parts of the technical solutions will not be repeated here.

[0070] This embodiment provides a PCB warpage detection system. The detection system adopts the detection device in Embodiment 1 and the detection method provided in Embodiment 2 to realize the detection of PCB warpage. The system includes a feeding module, a detection module and unloading module.

[0071] The loading module is used to place the PCB board to be tested on the detection table. The detection module adopts the detection method provided in Embodiment 2 to detect the warpage of the PCB board to be tested, and the unloading module unloads the detected PCB board. In this embodiment, the unqualified PCB boards are eliminated, and the qualified PCB boards are sent to the next process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com