Automatic reset rotary printing table applied to 3D printer

A 3D printer and automatic reset technology, applied in the field of 3D printing, can solve the problems of workpiece deformation, insufficient adhesion between the workpiece and the printing table, unfavorable printing work, etc., and achieve the effect of improving the forming rate of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

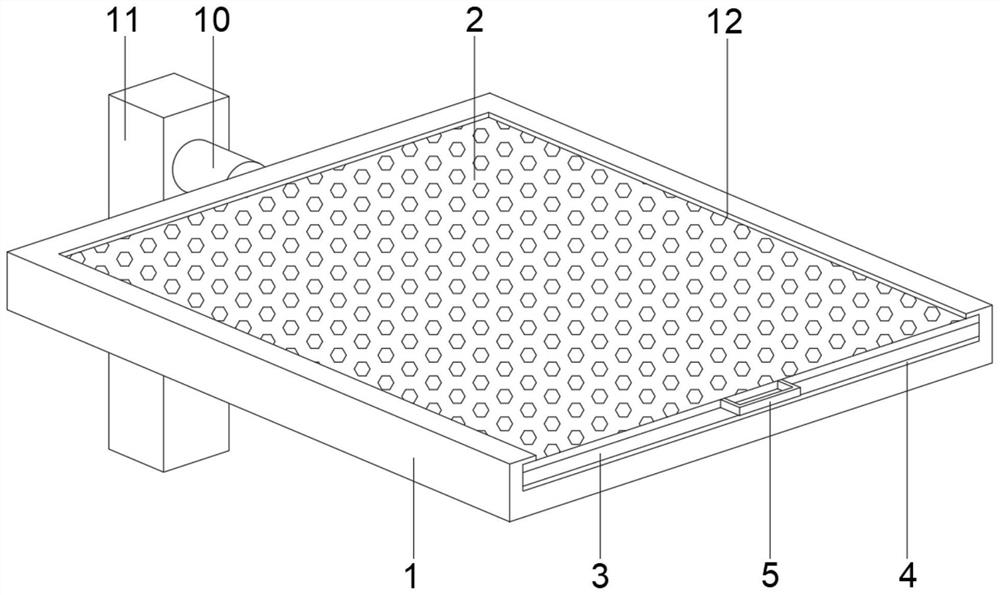

Embodiment 1

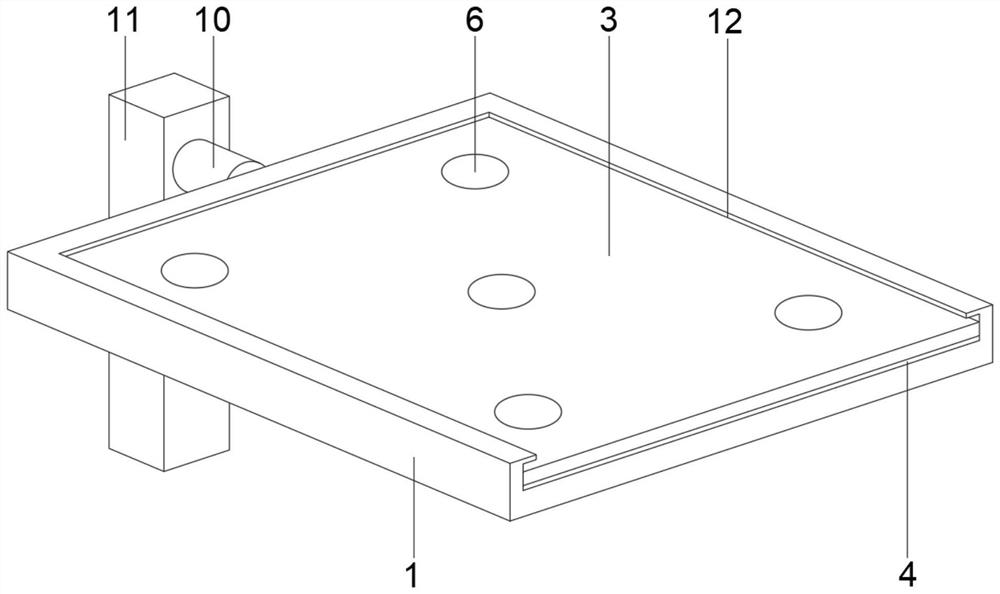

[0027] One end of the constant temperature heating tube 7 is electrically connected with a heating tube electrode 8, and the number of the heating tube electrodes 8 is provided in two groups, which are electrically connected at both ends of the constant temperature heating tube 7, and the constant temperature heating tube 7 is S-shaped. Embedded inside the constant temperature heating plate 3 .

Embodiment 2

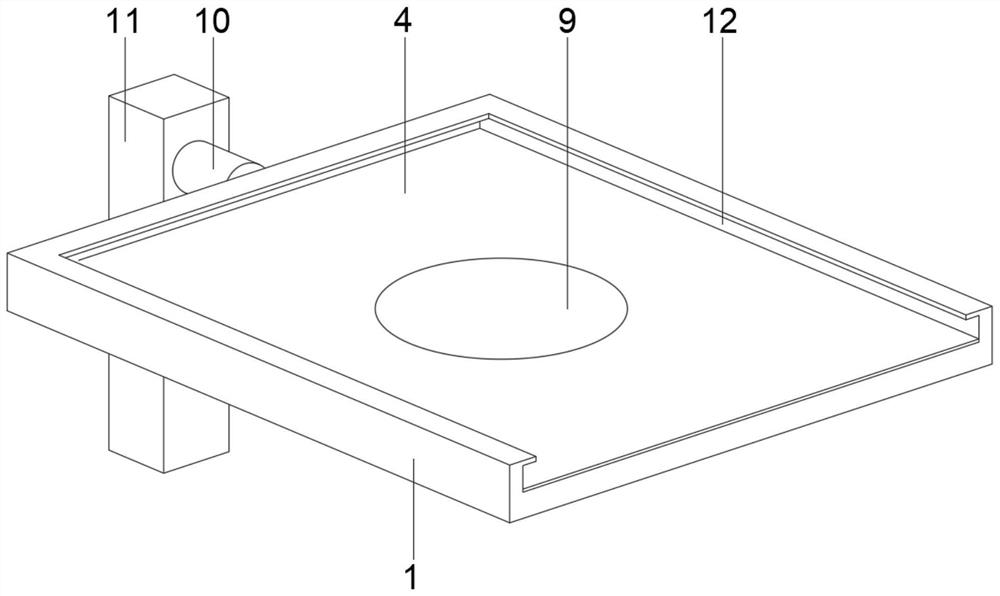

[0029] A level monitor 9 is embedded inside the buffer and heat insulating pad 4 .

Embodiment 3

[0031] One end of the outer casing 1 of the printing table is fixedly connected with a printing table rotating shaft 10 , and one end of the printing table rotating shaft 10 is provided with a printing table lifting control rod 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com