Processing process for mugwort tea

A processing technology, the technology of wormwood tea, applied in the field of processing technology of wormwood tea, can solve the problems of reducing the quality of the final wormwood tea, easy contact of wormwood with air, and oxidation of active ingredients of wormwood, so as to shorten the production cycle, The effect of retaining nutrients and improving color quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

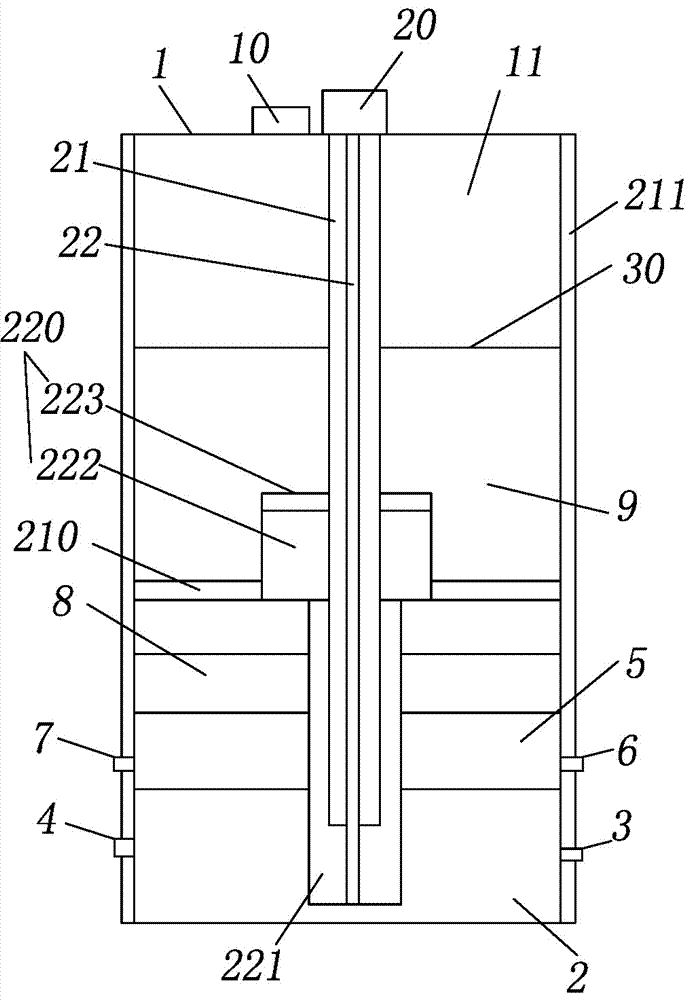

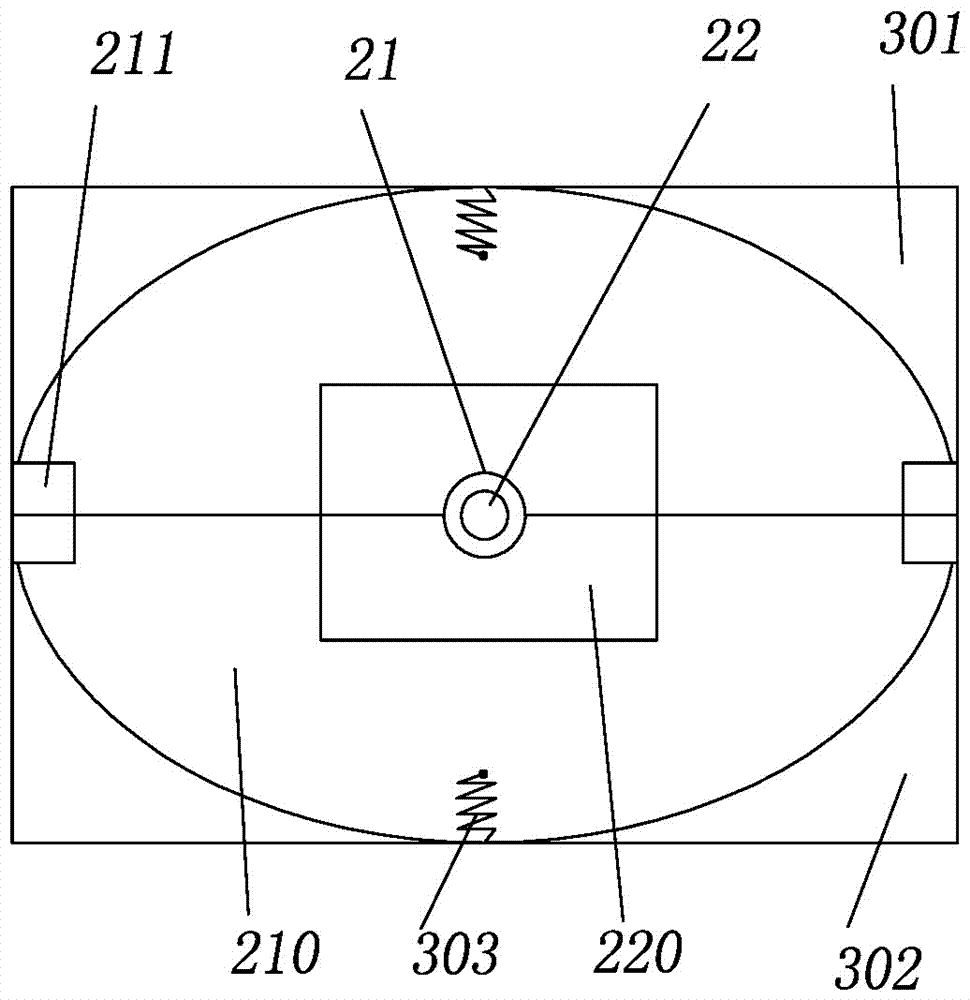

[0018] The structure of the special processing device in this embodiment is as figure 1 As shown, the cavity 1 is included, the top of the cavity 1 is provided with a material port 10, the material port 10 is provided with a cover capable of opening or closing the material port 10, and the top of the cavity 1 is also equipped with a motor 20, the output of the motor 20 The shaft is connected with a screw rod 21 and a flexible shaft 22, and the screw rod 21 is located on the central axis of the cavity 1, the screw rod 21 is hollow, and the flexible shaft 22 is located in the screw rod 21; There is a material basket connected to the upper rotation; figure 2 As shown, the shape of the support plate 210 is oval, and the two ends of the support plate 210 are provided with grooves. Connected in the groove of the support plate 210, so as to fix the support plate 210, ensure that the support plate 210 can move up and down along the screw rod 21; the material basket includes a grid-l...

Embodiment 2

[0021] The difference between this example and example 1 is: Step (2) hot water at 100°C for 30 seconds; step (3) cold water at 2°C for 5 minutes; step (4) dehydration time is 3 minutes; step (5) The temperature of the hot air is 70°C, and the kneading time is 15 minutes; in step (6), the initial temperature of the hot air is 40°C, slowly rising to 100°C, and the drying time is 20 minutes, and the moisture content of the prepared wormwood tea is 3% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com