A kind of preparation method of nanocellulose airgel microsphere coated filter paper

A technology of nano-cellulose and airgel, which is applied in the direction of surface coating liquid devices, separation methods, chemical instruments and methods, etc., can solve the problems of complicated preparation process and expensive modified filter paper materials, and achieve simple preparation steps, The effect of easy operation of the preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

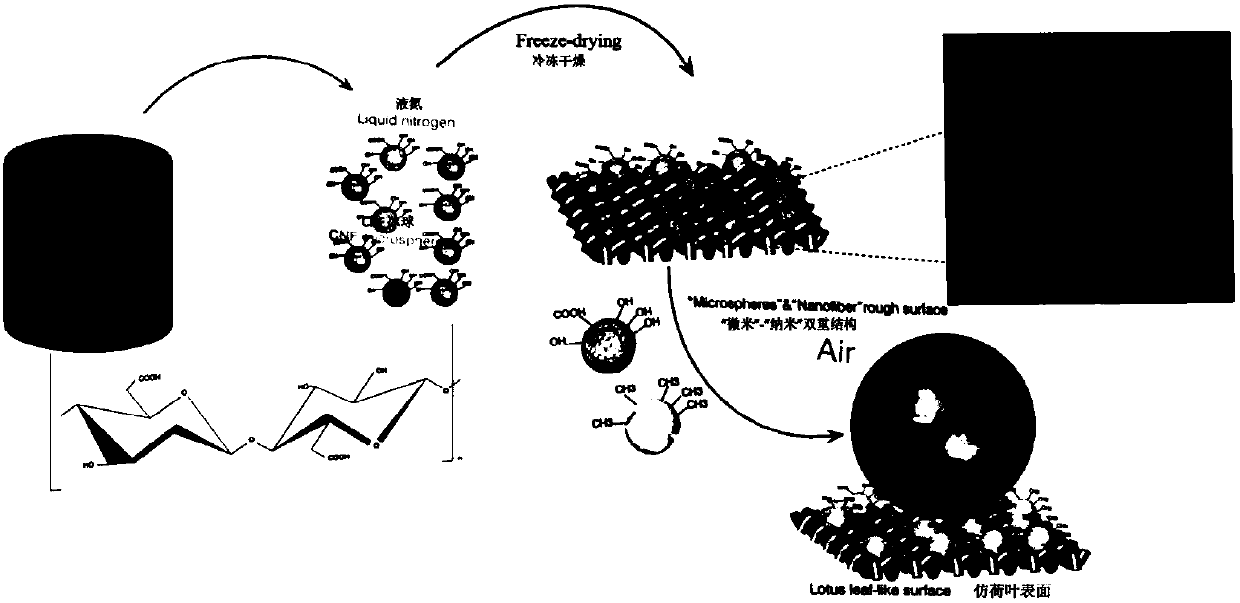

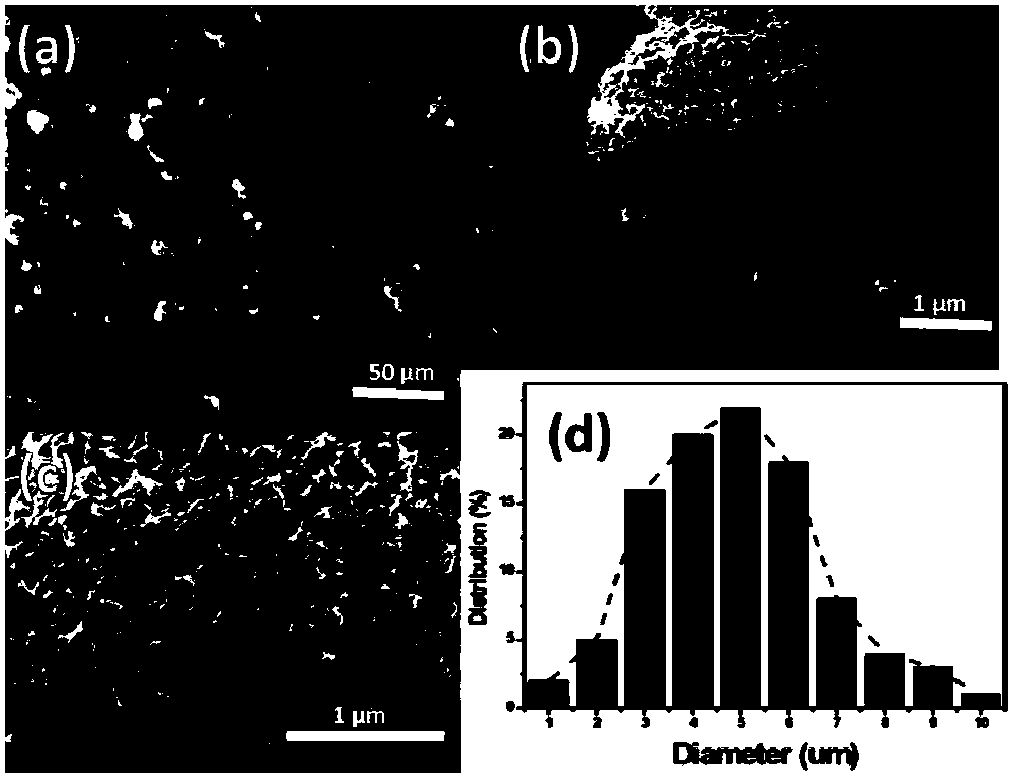

[0034] A preparation method for nanocellulose airgel microsphere coated filter paper, comprising the following steps: (the schematic diagram of the preparation process is shown in figure 1 )

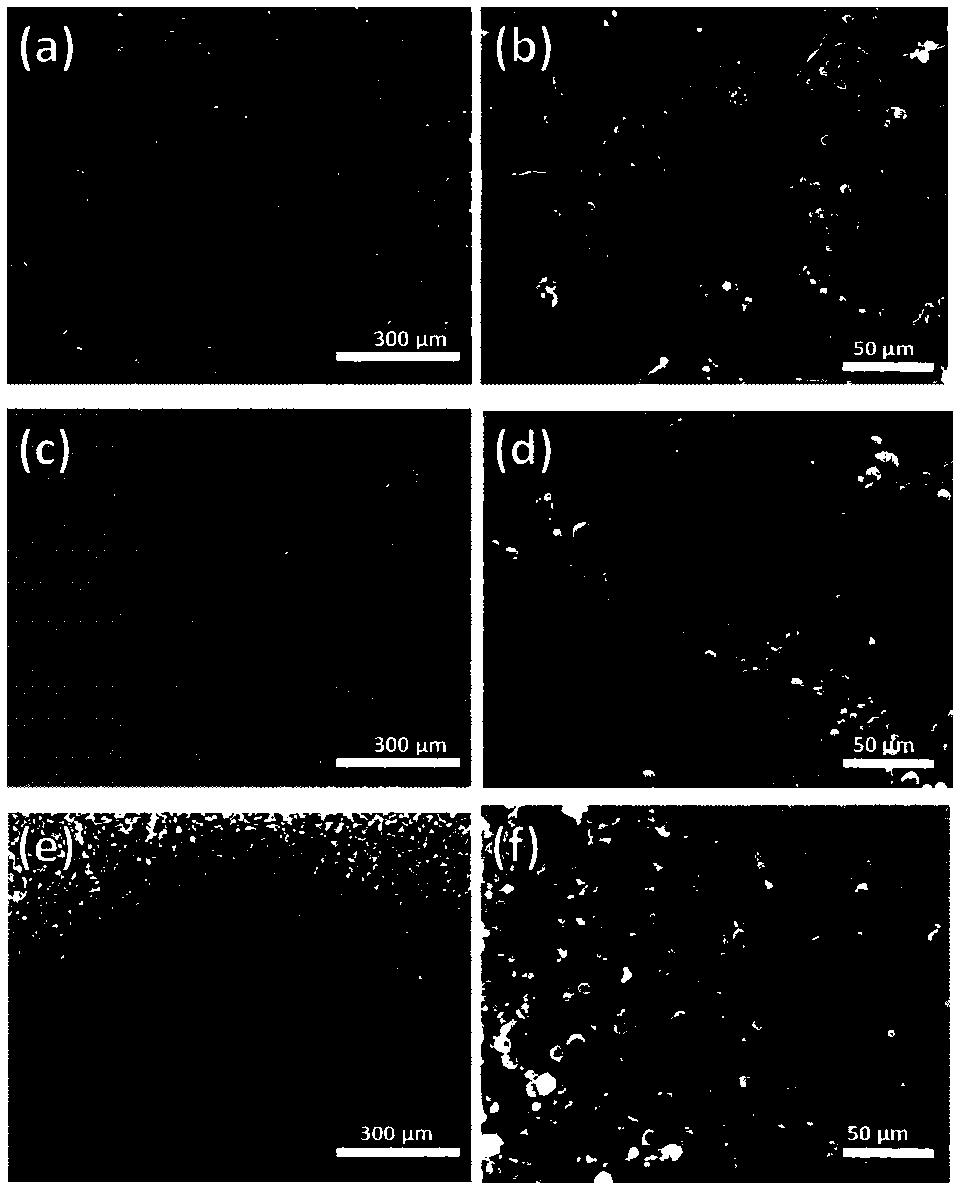

[0035] (1) Smear the nanocellulose ice crystal microsphere containing PAE resin on the industrial filter paper under low-temperature liquid nitrogen, wherein the content of PAE resin is 1.5% of the nanocellulose ice crystal microsphere weight, then place-50 ℃ and freeze Dry for 12 hours;

[0036] (2) Place the gel-linked coated filter paper obtained by freeze-drying in step (1) in a vacuum environment, and react at 120° C. for 3 hours to obtain nanocellulose airgel microsphere-coated filter paper.

[0037] Silanization modification treatment: the nanocellulose airgel microsphere coating filter paper of step (2) gained and methyldimethoxysilane are placed in the airtight container together, and wherein, the volume of methyldimethoxysilane is 10% of the volume of the filter paper coated ...

Embodiment 2

[0039] A preparation method for nanocellulose airgel microsphere coated filter paper, comprising the following steps:

[0040] (1) Smear the nanocellulose ice crystal microsphere containing PAE resin on the industrial filter paper under low-temperature liquid nitrogen, wherein the content of PAE resin is 1.3% of the nanocellulose ice crystal microsphere weight, then place-55 ℃ and freeze Dry for 12.5 hours;

[0041] (2) Place the gel-linked coated filter paper obtained by freeze-drying in step (1) in a vacuum environment, and react at 118° C. for 3 hours to obtain nanocellulose airgel microsphere-coated filter paper.

[0042] Silanization modification treatment: the nanocellulose airgel microsphere coating filter paper of step (2) gained and methyldimethoxysilane are placed in the airtight container together, and wherein, the volume of methyldimethoxysilane is 8% of the volume of the filter paper coated with nanocellulose airgel microspheres was reacted at 68° C. for 2.8 hour...

Embodiment 3

[0044] A preparation method for nanocellulose airgel microsphere coated filter paper, comprising the following steps:

[0045] (1) Smear the nanocellulose ice crystal microsphere containing PAE resin on the industrial filter paper under low temperature liquid nitrogen, wherein the content of PAE resin is 1.8% of the nanocellulose ice crystal microsphere weight, then place-50 ℃ and freeze Dry for 12 hours;

[0046] (2) Place the gel-linked coated filter paper obtained by freeze-drying in step (1) in a vacuum environment, and react at 125° C. for 3.2 hours to obtain nanocellulose airgel microsphere-coated filter paper.

[0047] Silanization modification treatment: the nanocellulose airgel microsphere coating filter paper of step (2) gained and methyldimethoxysilane are placed in the airtight container together, and wherein, the volume of methyldimethoxysilane is 12% of the volume of the filter paper coated with nanocellulose airgel microspheres was reacted at 73° C. for 3.4 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com