Method for preparing hollow structure carbon fibers by using cotton as raw material

A carbon fiber and raw material technology, applied in the field of preparing hollow structure carbon fiber, can solve problems such as environmental hazards, and achieve the effects of high adsorption capacity, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

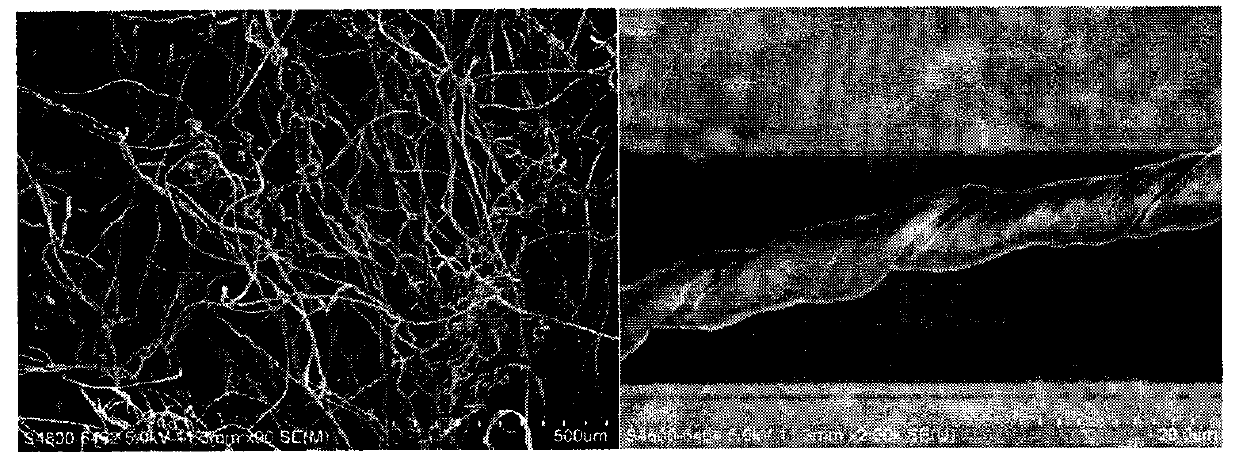

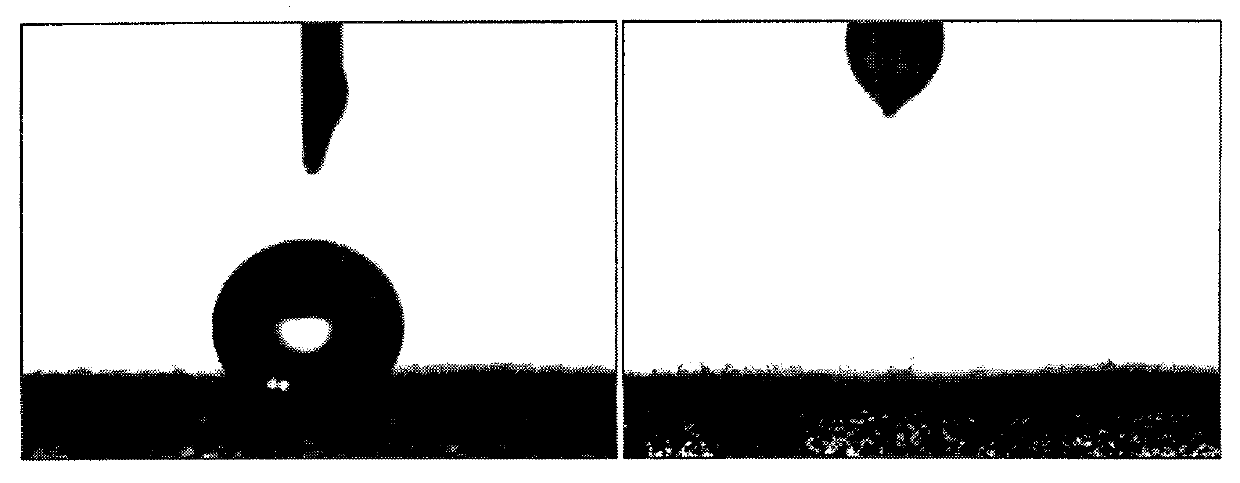

[0029] The cotton raw material without any treatment was directly placed in a tube furnace, under the protection of nitrogen, the gas flow rate was 1mL / min, and the heating rate was 2°C / min, and carbonized at a high temperature of 400°C for 1 hour. After the reaction, cool down to room temperature under the protection of nitrogen to prepare hollow carbon fibers. Depend on figure 1 It can be seen that the carbon fiber made from cotton after carbonization at 400°C has a complete structure, and the fiber length is about 1 to 5 cm. Depend on figure 2 It can be seen that the contact angle formed by water droplets on the surface of carbon fibers is >150°, while oil droplets are completely absorbed on the surface. Therefore, the prepared carbon fibers are superhydrophobic and lipophilic. Depend on image 3 It can be seen that the fiber material (CCFs-400) prepared at 400 °C is mainly composed of amorphous carbon and graphite grains. Depend on Figure 4 It can be seen that the ...

Embodiment 2

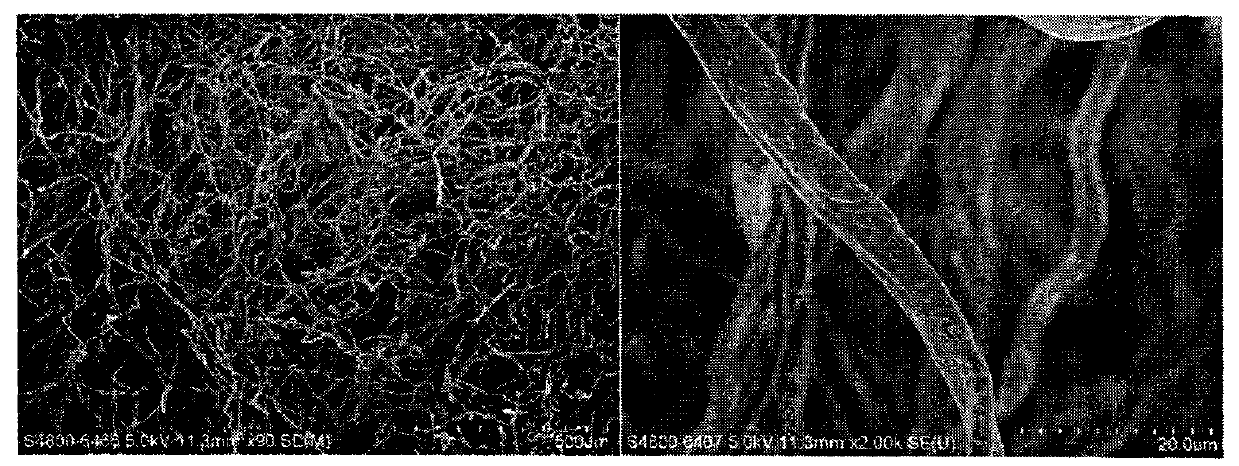

[0031] The cotton raw material without any treatment was directly placed in a tube furnace, under the protection of nitrogen, the gas flow rate was 1mL / min, and the heating rate was 2°C / min, and carbonized at a high temperature of 600°C for 1 hour. After the reaction, cool down to room temperature under the protection of nitrogen to prepare hollow carbon fibers. Depend on Figure 5 It can be seen that the carbon fibers prepared from cotton after carbonization at 600 °C are still structurally intact. Depend on Figure 6 It can be seen that the carbon fiber has a hollow structure with a pore size of about 4.6 μm. This novel structure can greatly improve the adsorption performance of carbon fibers, and it is convenient to recover the adsorbed substances from the micropores. Depend on image 3 It can be seen that the fiber material (CCFs-600) prepared at 600 °C is mainly composed of amorphous carbon and graphite grains. Depend on Figure 4 It can be seen that the adsorption ...

Embodiment 3

[0033] The cotton raw material without any treatment is directly placed in a tube furnace, under the protection of nitrogen, the gas flow rate is 2mL / min, and the heating rate is 2°C / min, and it is carbonized at a high temperature of 800°C for 1 hour. After the reaction, cool down to room temperature under the protection of nitrogen to prepare hollow carbon fibers. Depend on Figure 7 It can be seen that the carbon fibers prepared from cotton after carbonization at 800 °C are still structurally intact. Depend on Figure 8 It can be seen that the carbon fiber has a hollow structure with a pore size of about 3.8 μm. Depend on image 3 It can be seen that the fiber material (CCFs-800) prepared at 800°C is mainly composed of amorphous carbon and graphite grains, and the peak at 2θ=44.36° is clearly visible, indicating that the content of graphite is increasing. Depend on Figure 4 It can be seen that the adsorption capacities of the prepared carbon fiber to peanut oil, ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com