Single IGBT inversion type manual arc welding machine universal for power supplies of both grids

A network power supply and inverter technology, applied in arc welding equipment, welding equipment, welding equipment, etc., to achieve high reliability, high efficiency and low cost production, and good market adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

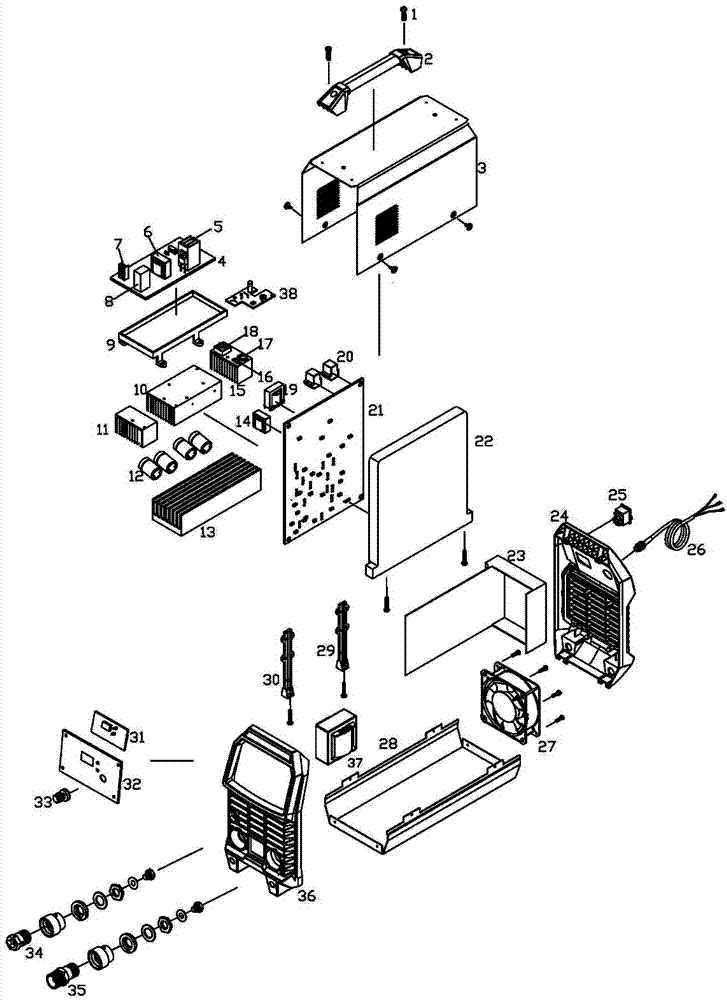

[0026] Such as figure 1 Shown, is the structural representation of a kind of IGBT inverter manual arc welding machine that utilizes the present invention to make, and the main components of its welding machine include:

[0027] 1) Shell part, including shell 3, handle 2, bottom plate 28, shell screws, etc.

[0028]2) The rear panel, the components installed on the rear panel mainly include: power switch 25, power cord 26, power cord that cannot be pulled off, rear plastic panel 24, cooling fan 27 and other parts; the power cord 26 is connected to the power grid. Power switch 25 controls the on or off of welding machine power supply. Cooling fan 27 is positioned at the rear portion of welder, and cold wind is carried out from the air intake hole of welder rear portion. It can make some heat-generating devices or components in the left circuit part, such as IGBT and radiator radiator, fast recovery diode and radiator and other components, be better cooled. Such design of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com