Integrated forming process for support and plate body of plastering plate

A plastering board and integrated technology, which is applied in the technical field of integral molding of the bracket and the board body, can solve problems such as gaps in stamping and welding, easy loosening, and high production costs, so as to reduce the difficulty of processing and reduce processing steps. The effect of high repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

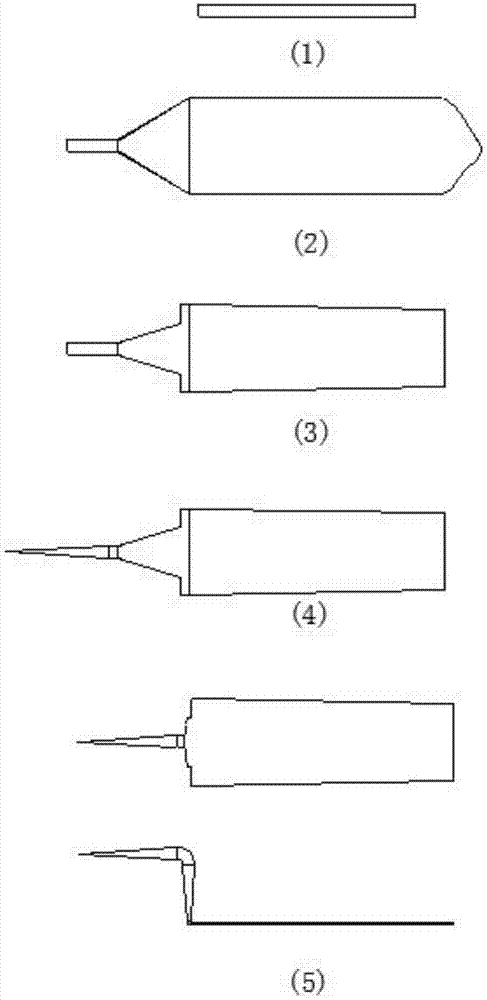

[0027] Such as figure 1 Shown, a kind of technology that the support of plasterboard and board body are integrally formed, comprises the following steps:

[0028] (1) blanking the coiled steel into a single steel blank;

[0029] (2) One end of the steel blank is rolled into a block plate, and the other end retains the original shape.

[0030] (3) take the obtained plate with a hot rolling mill to form the external dimensions after the support is horizontally connected with the plate body, to obtain the first semi-finished product;

[0031] (4) forging the tail of the first semi-finished product into the shape of a bracket with a forging press to obtain the second semi-finished product;

[0032] (5) Bending the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com