Full-automatic blood taking needle assembly machine

A blood collection needle and assembly machine technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of complex internal structure, inability to install the front spring and rear spring, and difficulty in separating them, achieving good stability and compact structure , the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

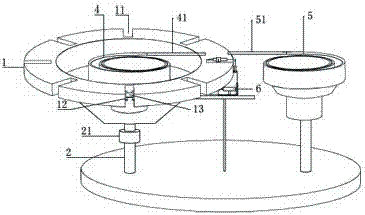

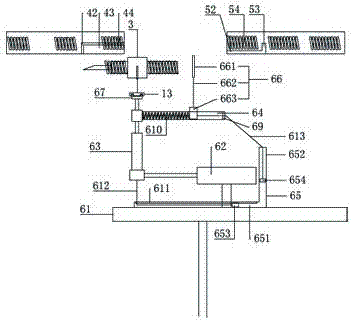

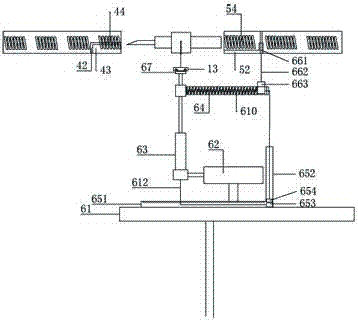

[0026] refer to Figure 1-7 As shown, a fully automatic assembling machine for blood collection needles in this embodiment includes a sample tray 1, a support frame 2 and a spring assembly workpiece, the support frame 2 is provided with a motor 21, and the sample tray 1 passes through several evenly distributed support columns and motors. The rotating shafts of 21 are connected, the sample tray 1 is a ring structure, the sample tray 1 is used to move the needle core 3 of the blood collection needle to be assembled to the station where the spring assembles the workpiece, the sample tray 1 is provided with a number of workpiece holes 11, and the workpiece holes 11 It is rectangular and extends to the outer edge of the sample tray 1. The long axis extension line of the workpiece hole 11 passes through the center of the sample tray 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com